Device for harmless treatment of high-temperature tail gas in combustion process

A technology of harmless treatment and combustion process, applied in separation devices, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of atmospheric environmental pollution, can not completely eliminate waste gas, etc., and achieve the effect of reducing the discharge temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical features, technical contents and technical effects of the present invention, the accompanying drawings of the present invention will now be described in more detail in conjunction with the embodiments.

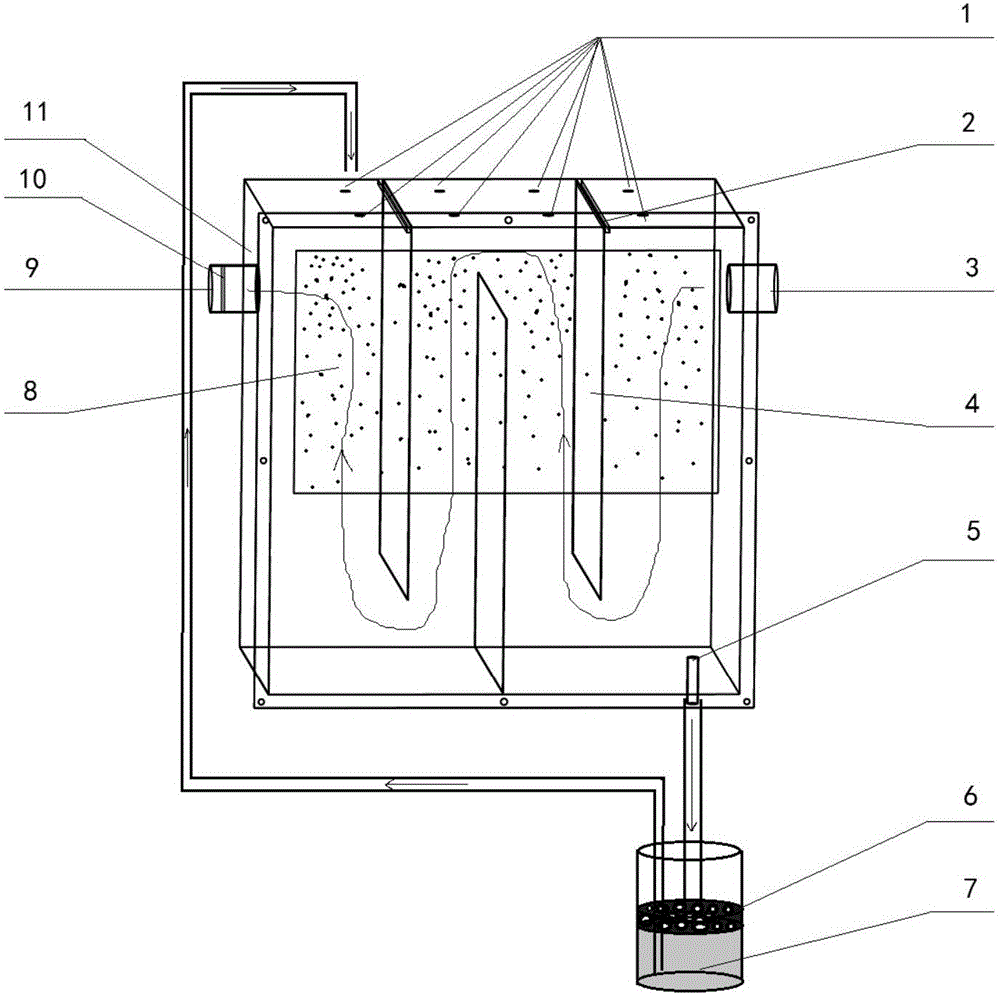

[0022] Such as figure 1 As shown, the present invention provides a device for harmless treatment of tail gas, which mainly includes a tail gas treatment device and a waste water treatment device. The tail gas treatment device includes a box body 11 , a nozzle 1 , three baffles 4 and an observation window 8 , and the waste water collection device mainly includes a waste water filter device 6 . When working, several nozzles produce fully atomized water mist to fill the entire box, and the three baffles 4 are fixed by the slot 2, mainly to change the trajectory of the exhaust gas, so that the exhaust gas and the water mist are fully mixed, and the absorption of exhaust gas particles is increased. ,Reduce the temperature. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com