Automobile exhaust thermal energy storing and converting method and device

A technology for thermal energy storage and automobile exhaust, which is used in exhaust devices, mufflers, internal combustion piston engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

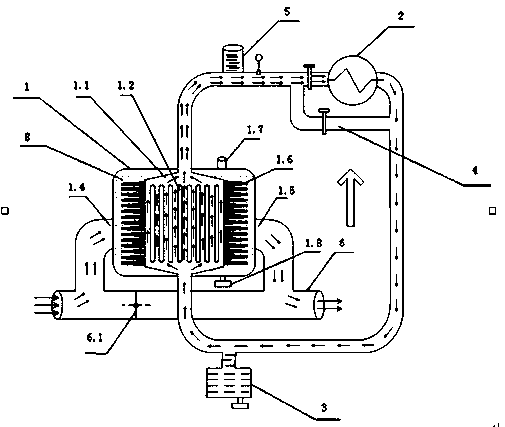

Embodiment 1

[0071] A tandem automobile exhaust thermal energy storage and conversion device, which is composed of an energy collection heat exchanger 1 and a plurality of energy use heat exchangers 2 connected in series, and each energy use heat exchanger 2 is connected in parallel with a bypass conductor with a valve F Oil pipe 4, the front end of each energy-using heat exchanger is provided with a valve F controlled; the front end of the energy-using heat exchanger combined in series is provided with an expansion and pressure reducing valve 5; , car wok 22, car water heater 23 or car water dispenser, car oven 24, such as Figure 6 shown;

[0072] When working, the 800°-1000° unstable high-temperature exhaust gas in the automobile exhaust pipe 6 is exchanged for heat through the energy-collecting heat exchanger 1, and the high-temperature heat transfer oil in the energy-collecting heat exchanger 1 is heated to 300°-500°. When needs work simultaneously with a plurality of energy-consumin...

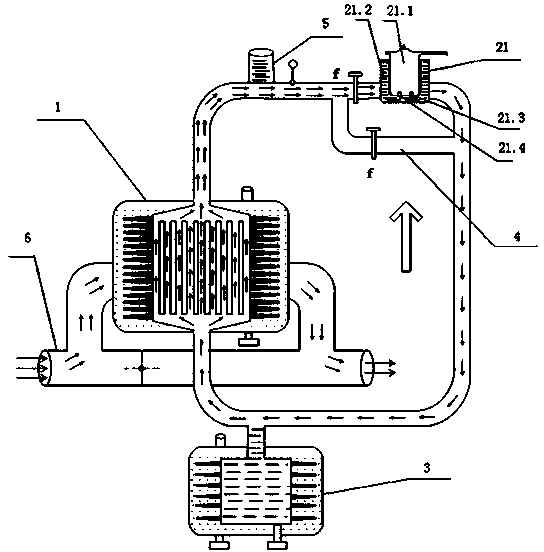

Embodiment 2

[0090] A parallel automobile exhaust thermal energy storage and conversion device, which is composed of an energy collection heat exchanger 1 and a plurality of energy utilization heat exchangers 2 connected in parallel, and each energy utilization heat exchanger is provided with a control valve F at the front end; parallel connection The front end of the combined energy-using heat exchanger is provided with an expansion and pressure reducing valve 5; the energy-consuming heat exchanger combined in parallel is composed of an automobile pressure cooker 21, an automobile frying pan 22, an automobile water heater 23 or an automobile water dispenser and an automobile oven 24 in parallel, And the parallel combined energy heat exchanger is connected in parallel with a bypass oil guide pipe 4 with a valve F, such as Figure 7 shown;

[0091] When working, the 800°-1000° unstable high-temperature exhaust gas in the automobile exhaust pipe 6 is exchanged for heat through the energy-col...

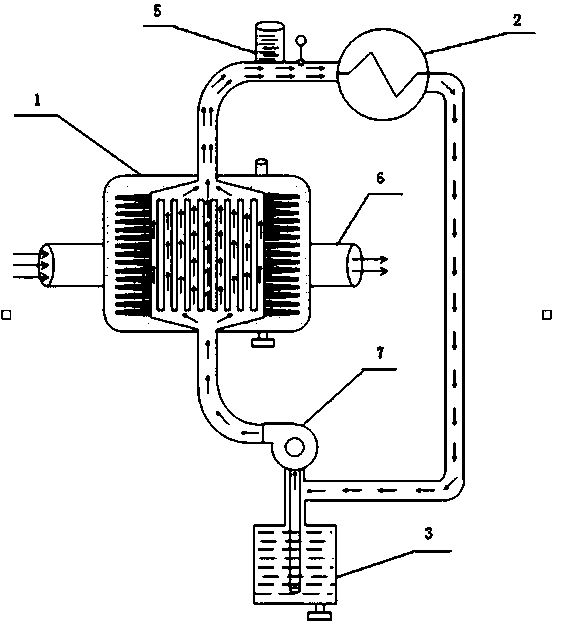

Embodiment 3

[0094] A parallel-connected automobile exhaust thermal energy storage and conversion device is to replace the energy-consuming heat exchanger 2 with a thermoelectric power generation device 9, which is composed of a thermoelectric heat exchanger 9.1, a semiconductor power generation module 9.2, and a radiator 9.3. The thermoelectric heat exchanger The input end of 9.1 communicates with the upper end of the energy-collecting heat exchanger 1 located between the automobile exhaust pipes 6 through the heat-conducting oil pipeline, and the output end of the temperature-difference heat exchanger 9.1 passes through the heat-conducting oil pipeline through the high-temperature oil pump 7 set on the thermal energy storage tank 3 and the collector. The lower end of the energy heat exchanger 1 is connected, and the heat exchange end face of the thermoelectric heat exchanger 9.1 is provided with a semiconductor power generation module 9.2, and the other end face of the semiconductor power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com