Deep recovery device for flue gas heat of power station boiler and method of deep recovery device

A recovery device and power plant boiler technology, applied in heat pumps, indirect heat exchangers, heat exchanger shells, etc., can solve problems such as heating attenuation and difficulty in starting lithium bromide at low temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

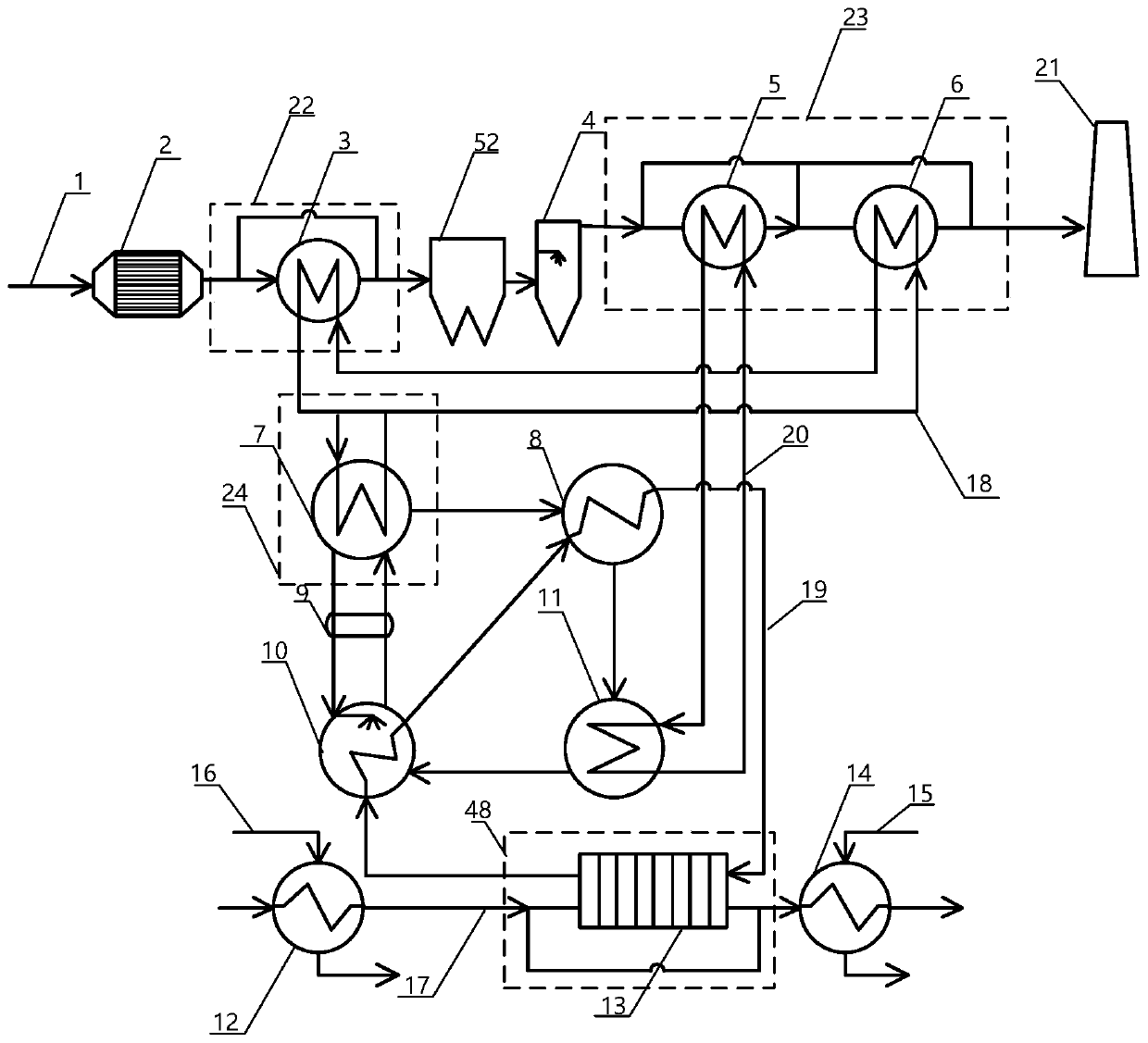

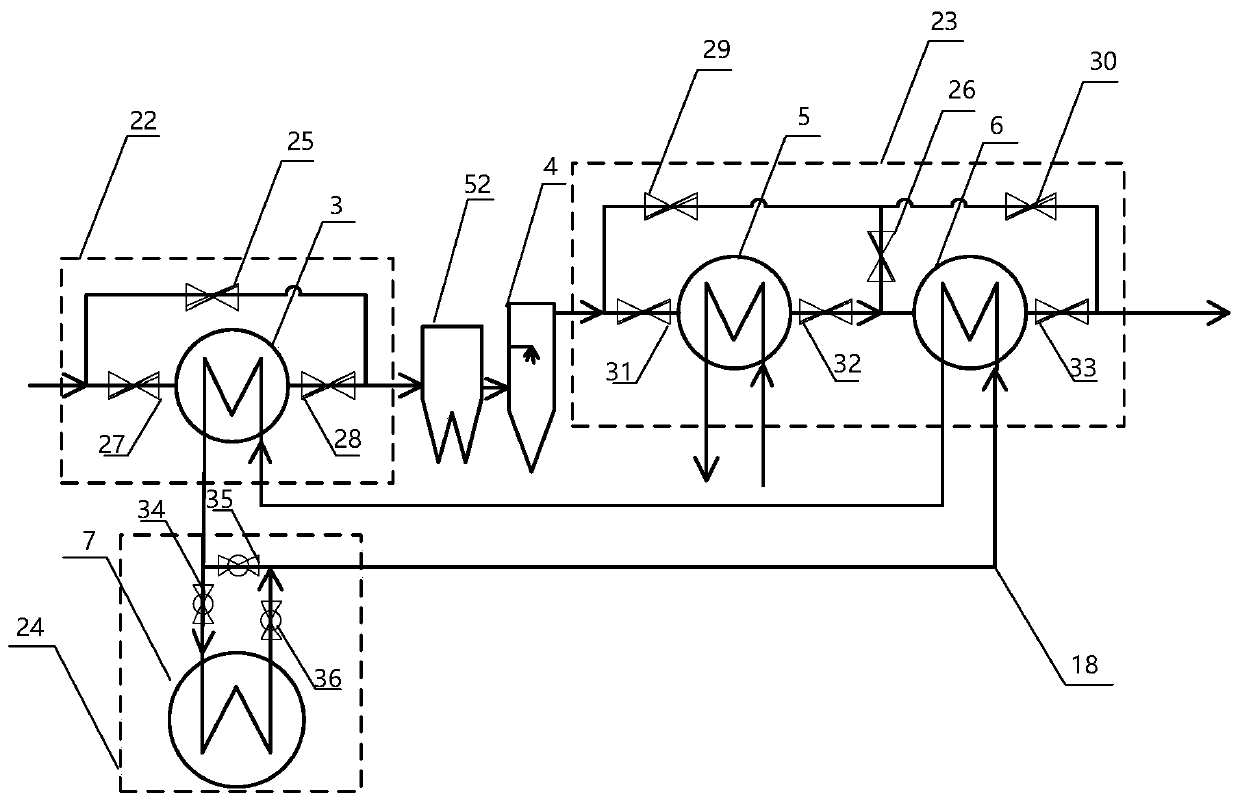

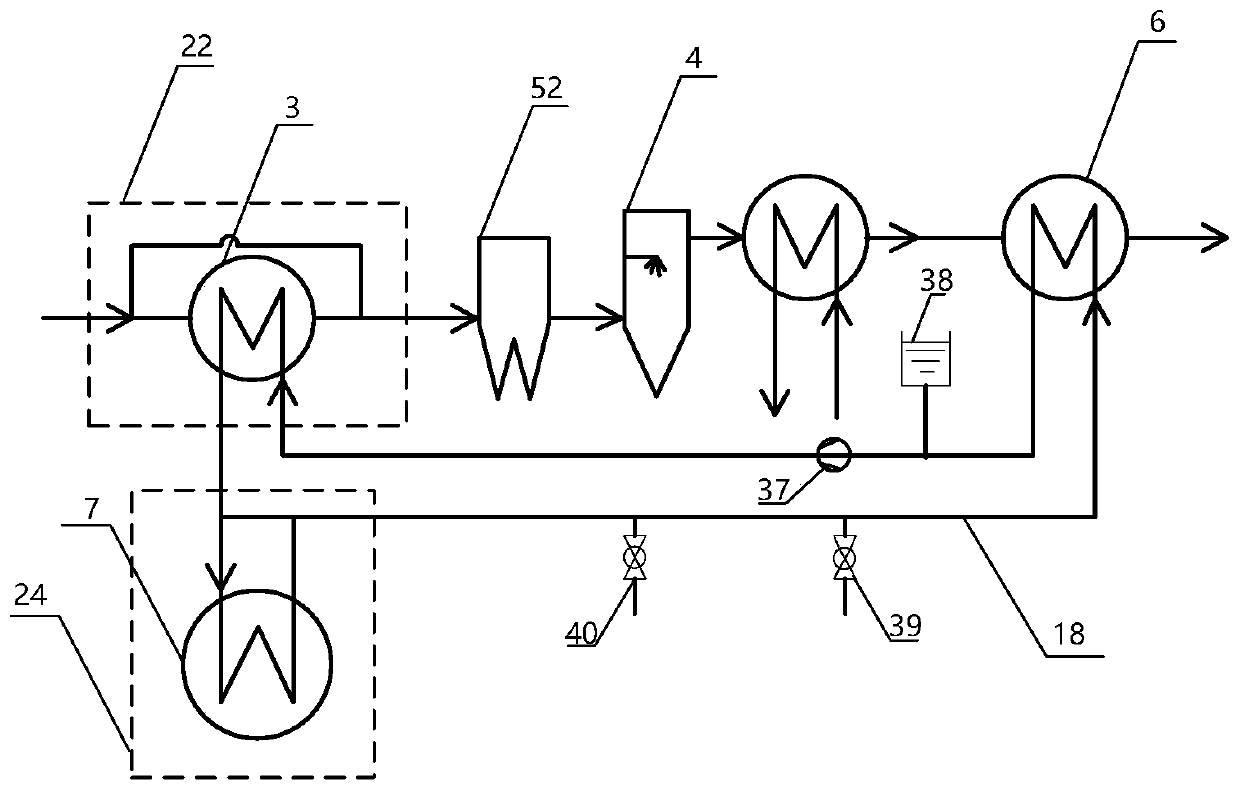

[0029] Example 1: A deep recovery device for exhaust waste heat of power plant boilers, including sensible heat exchangers, latent heat exchangers, flue gas heaters, hot water absorption heat pumps, plate heat exchangers, water pipes and flue , the sensible heat of the utility boiler exhaust flue gas is firstly recovered by the sensible heat exchanger, the flue gas inlet of the sensible heat exchanger is connected with the flue gas outlet of the air preheater, and the flue gas outlet of the sensible heat exchanger is connected with the flue gas inlet of the dust collector, The outlet of the circulating water in the sensible heat exchanger is connected to the inlet of the heat source driven by the absorption heat pump generator, and then the flue gas from the power station boiler enters the latent heat exchanger after being desulfurized by the desulfurization tower, and the latent heat of vaporization of the water vapor in the flue gas is recovered and used for latent heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com