Penetrating type reverse-flow drying device

A drying device and penetrating technology, applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems that cannot meet the needs of modern production and life, slow drying speed, large volume, etc., and achieve reduction Effects of steam consumption, lower discharge temperature, and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

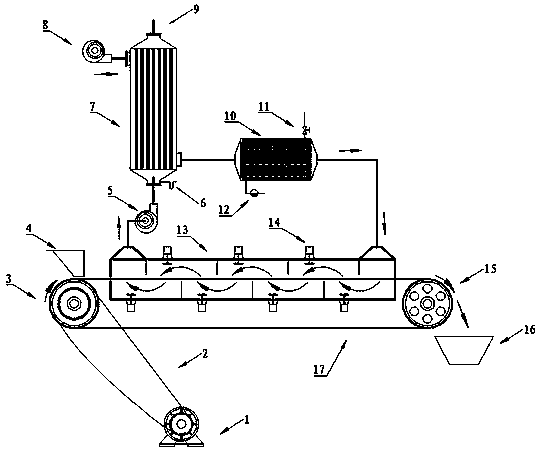

[0014] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0015] like figure 1 The shown penetrating countercurrent drying device includes a heat exchanger 7, an air heater 10, a driving drum 3, a driven drum 15, a sieve plate type conveying steel belt 17 and a dryer main body 13, wherein the heat exchanger 7 The upper side is connected to the blower 8, and the lower side is connected to the air heater 10. The driving drum 3 is connected to the double-stage cycloid reducer 1 through the transmission chain 2. The driving drum 3 and the driven drum 15 pass through the sieve plate type The conveying steel belt 17 constitutes a material transmission system, one end of the material transmission system is provided with a hopper 4, and the other end is provided with a hopper 16, and the sieve plate type conveying steel belt 17 passes through the main body 13 of the dryer, which is sealed structure, a plurality of axial flow fans 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com