Low-temperature refining technology for plant oil through four-step method

A low-temperature refining, four-step technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of vitamin, long-chain unsaturated fatty acid destruction, carcinogen styrene-to-propanol ratio and trans fatty acid, and high input cost of production equipment , to achieve the effect of improving oil quality, improving flavor and stability, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

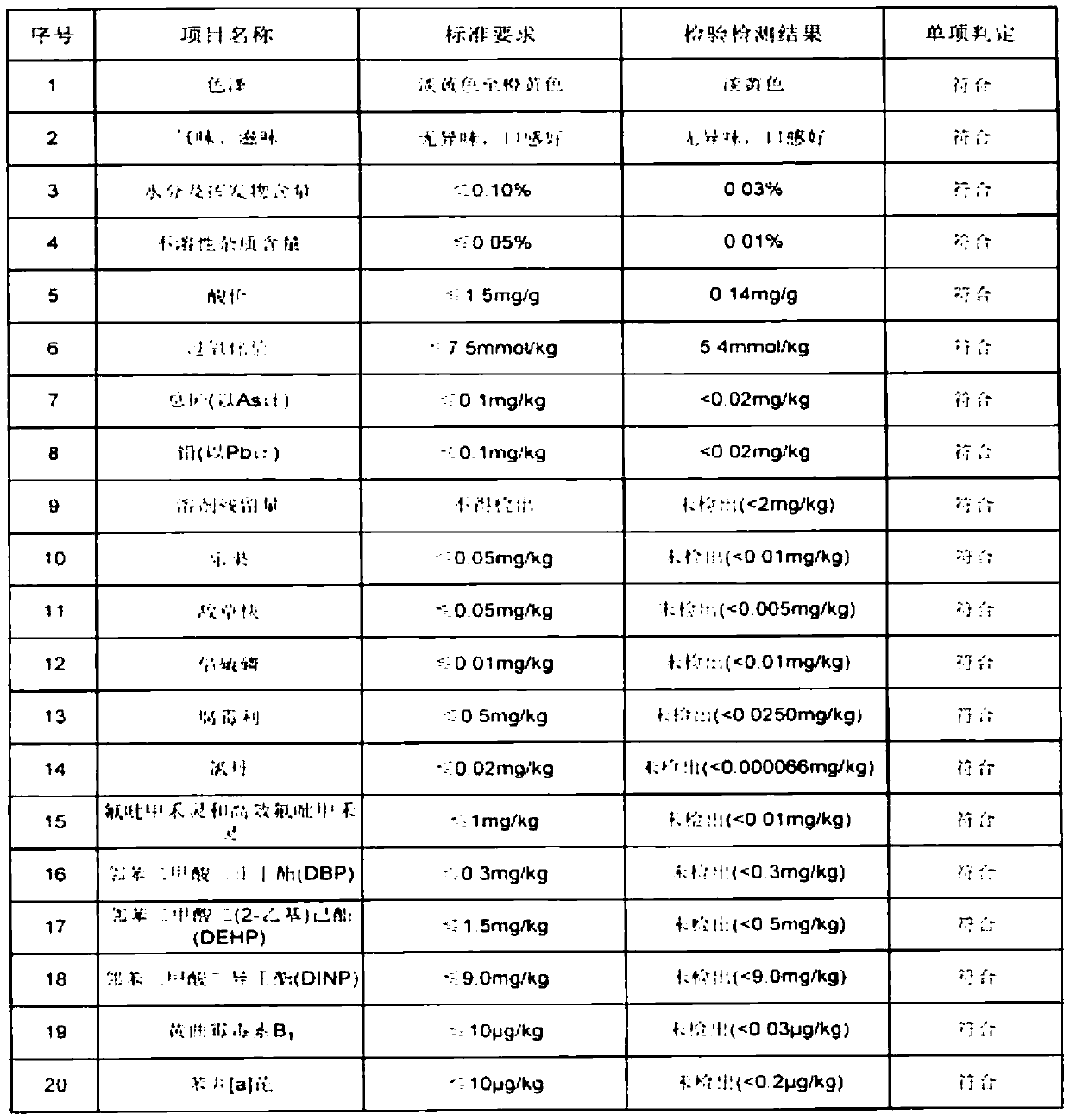

[0030] Example 1: A four-step low-temperature refining process for vegetable oil, which includes the following steps: (1) hydration; (2) purification; (3) purification; (4) winterization;

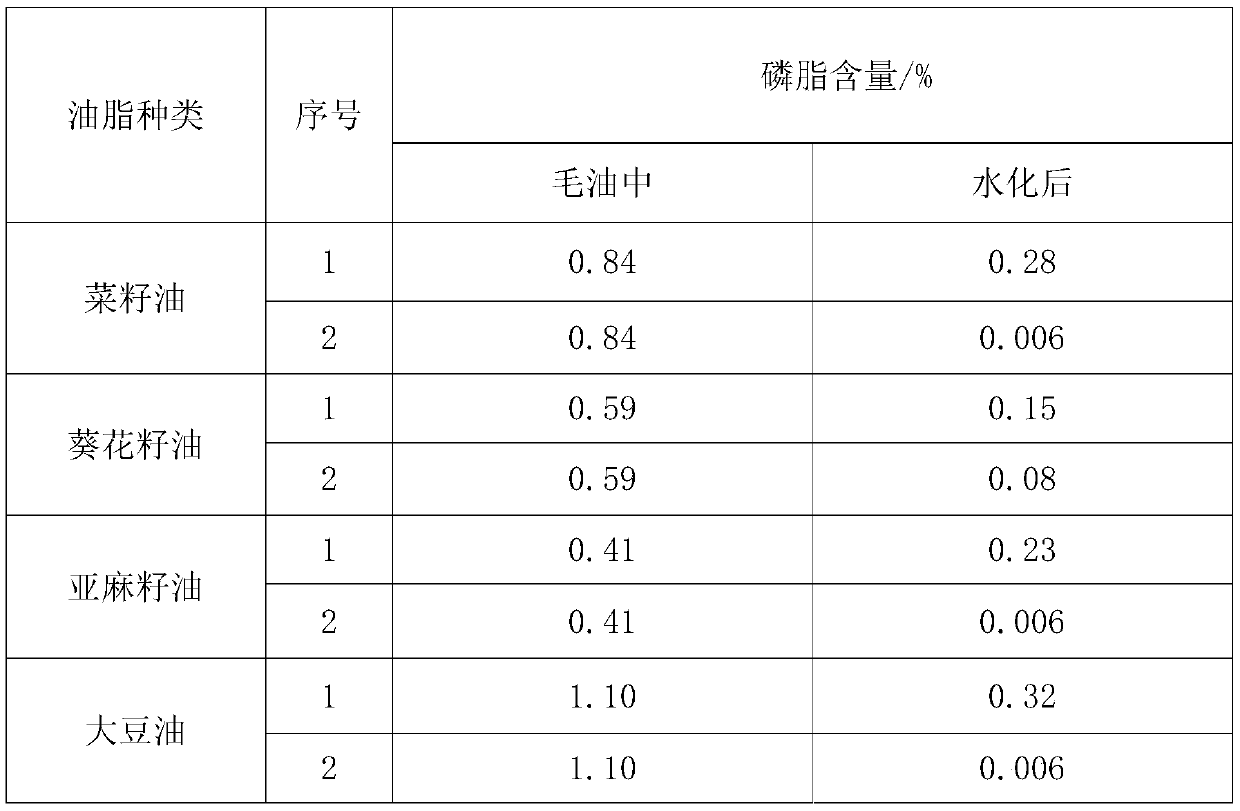

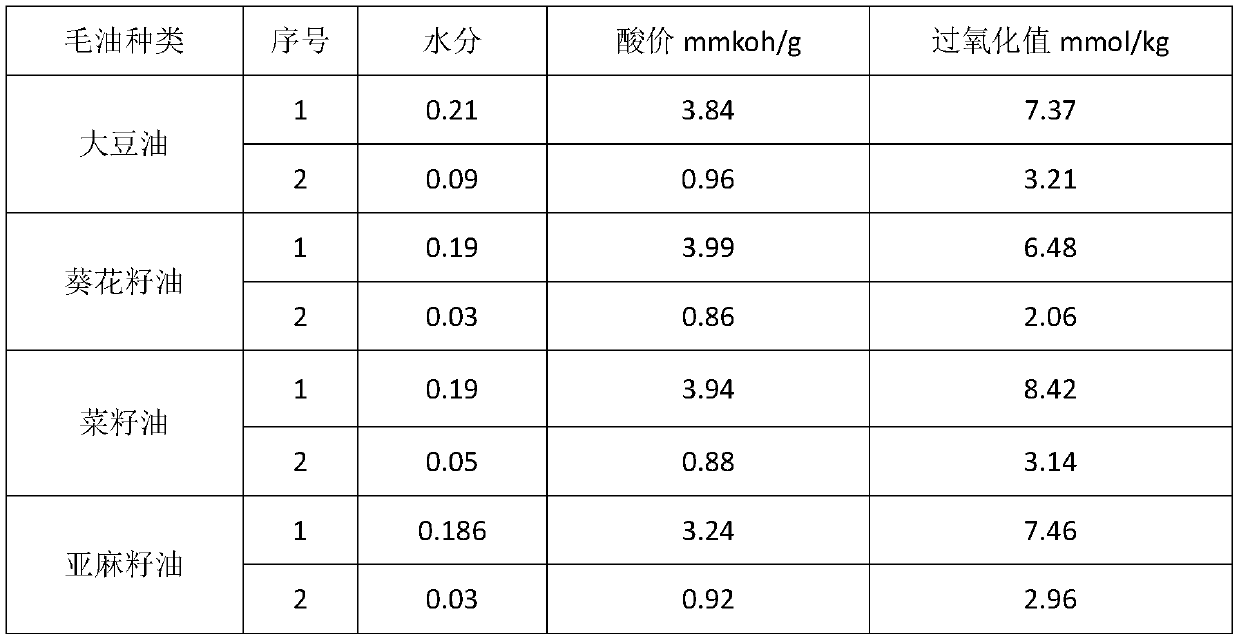

[0031] (1) Hydration: The crude oil is heated to 55°C, and then the gradient water addition method is adopted. The total water quality is twice the gum content in the crude oil, and the water temperature is controlled at 10°C higher than the oil temperature to obtain the hydrated grease ; Using the hydration method of the present invention to remove the phospholipids and part of the protein and gum in the crude oil, ensure the quality of the oil, and extend the shelf life of the vegetable oil to a greater extent.

[0032] The specific steps of the gradient water addition method are:

[0033] The quality of the first water added is 50% of the total quality of water added. During the process of adding water, stir at 60 rpm for 20 minutes to make the hydrophilic phospholipids rapidly absorb water, sw...

Embodiment 2

[0048] Example 2: A four-step low-temperature refining process for vegetable oil, which includes the following steps: (1) hydration; (2) purification; (3) purification; (4) winterization; wherein,

[0049] (1) Hydration: The crude oil is heated to 72°C, and then a gradient water addition method is used. The total water quality is 3 times the gum content in the crude oil. The water temperature is controlled at 13°C higher than the oil temperature to obtain the hydrated grease ; Using the hydration method of the present invention to remove the phospholipids and part of the protein and gum in the crude oil, ensure the quality of the oil, and extend the shelf life of the vegetable oil to a greater extent.

[0050] The specific steps of the gradient water addition method are:

[0051] The quality of the first water added is 60% of the total quality of water added. During the process of adding water, stir at 70 rpm and stir for 30 minutes to make the hydrophilic phospholipids rapidly absor...

Embodiment 3

[0066] Example 3: A four-step low-temperature refining process for vegetable oil, which includes the following steps: (1) hydration; (2) purification; (3) purification; (4) winterization;

[0067] (1) Hydration: The crude oil is heated to 60°C, and then a gradient water addition method is used. The total water quality is 2.5 times the gum content in the crude oil, and the water temperature is controlled at 12°C higher than the oil temperature to obtain hydrated grease ; Using the hydration method of the present invention to remove the phospholipids and part of the protein and gum in the crude oil, ensure the quality of the oil, and extend the shelf life of the vegetable oil to a greater extent.

[0068] The specific steps of the gradient water addition method are:

[0069] The quality of the first water added is 55% of the total quality of water added. During the process of adding water, stir at 65 rpm for 25 minutes to make the hydrophilic phospholipids rapidly absorb water, swell, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com