Apparatus for improving sulfur recovery ability of sulfur melting system

A technology of sulfur recovery and capacity, applied in the direction of sulfur compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of insufficient stillness and sedimentation of sulfur foam, and achieve the effect of reducing temperature, uniform heating and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

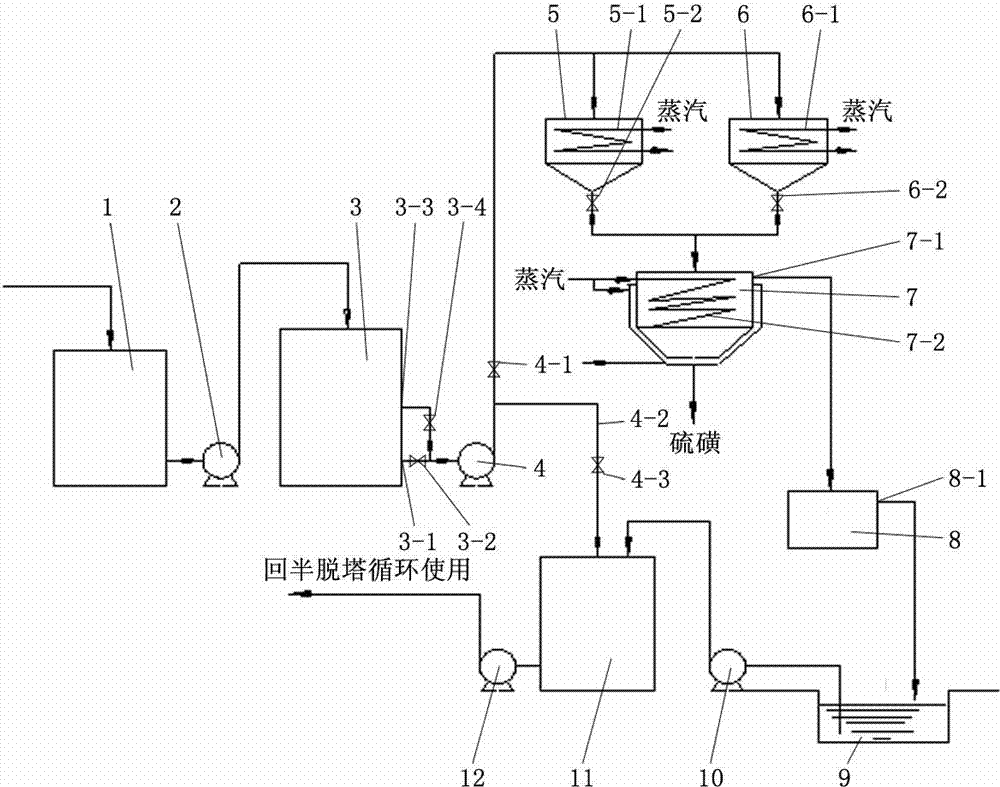

[0017] figure 1 The equipment shown to improve the sulfur recovery capacity of the sulfur melting system mainly includes an oxidation regeneration tank 1, an intermediate tank 3, an elevated tank, a sulfur melting tank 7, a settling tank 8, a cooling tank 9 and a rich solution tank 11; In addition to the sulfur foam outlet 3-1 originally opened in the lower part, a liquid outlet 3-3 is also opened in the middle; the equipment has two high-level tanks, and the two high-level tanks are the first high-level tank 5 and the second high-level tank. Slot 6, steam heating coils 5-1 and 6-1 for feeding steam are respectively arranged in the two high-level tanks, and valves 5-2 and 6-2 are respectively arranged at the discharge ports of each high-level tank; sulfur melting kettle 7 The upper part of the separator is provided with a separator, the separator is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com