Internal and external cyclone reverse shunting-type air dedusting method and device

An air dust removal and split flow technology, which is applied in the field of air purification, can solve the problems of limited use range, high space requirements for the use site, and high noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below with reference to the accompanying drawings and preferred specific embodiments of the present invention.

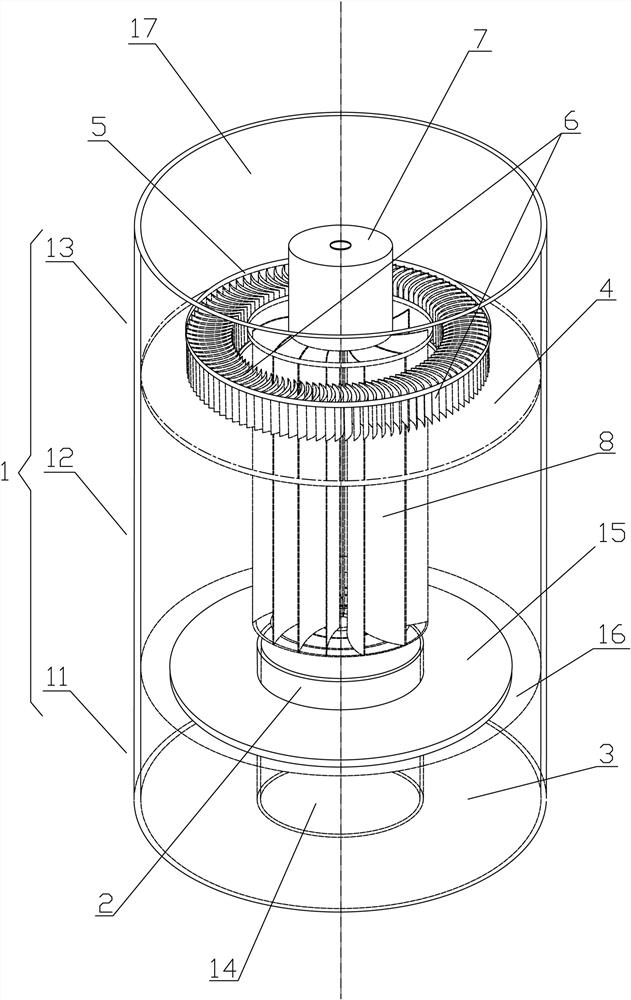

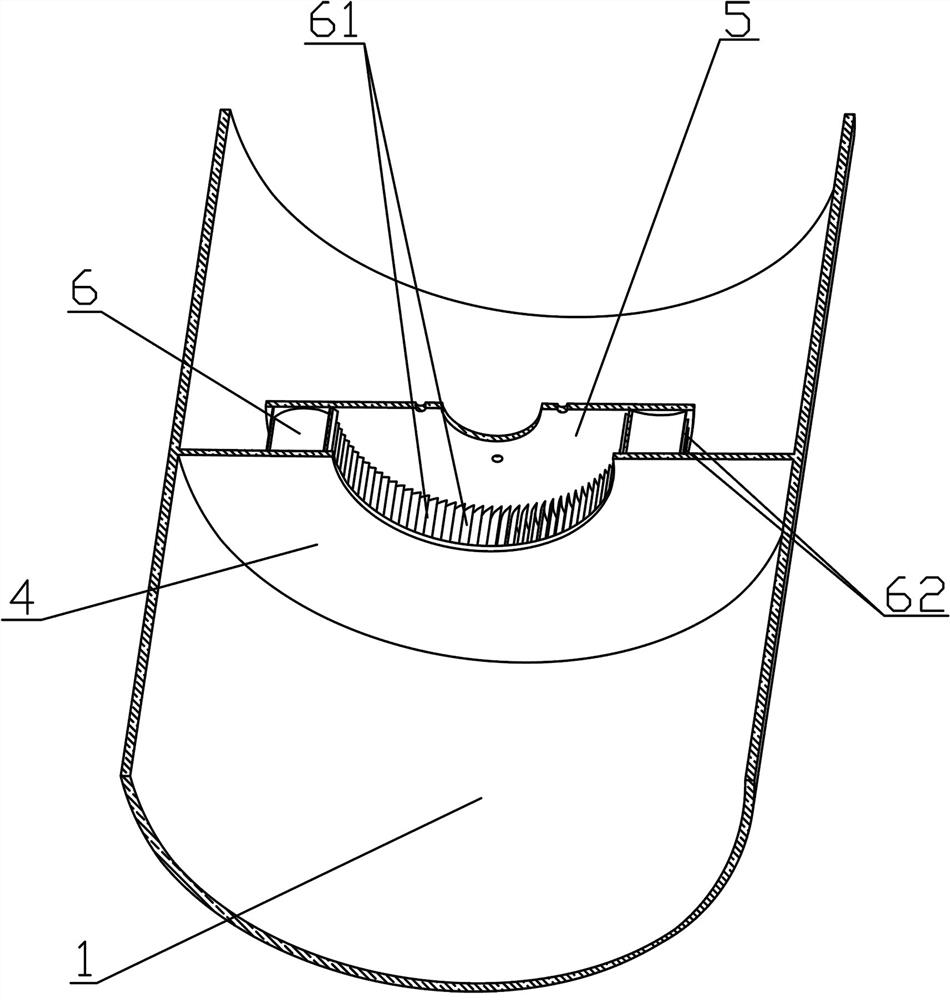

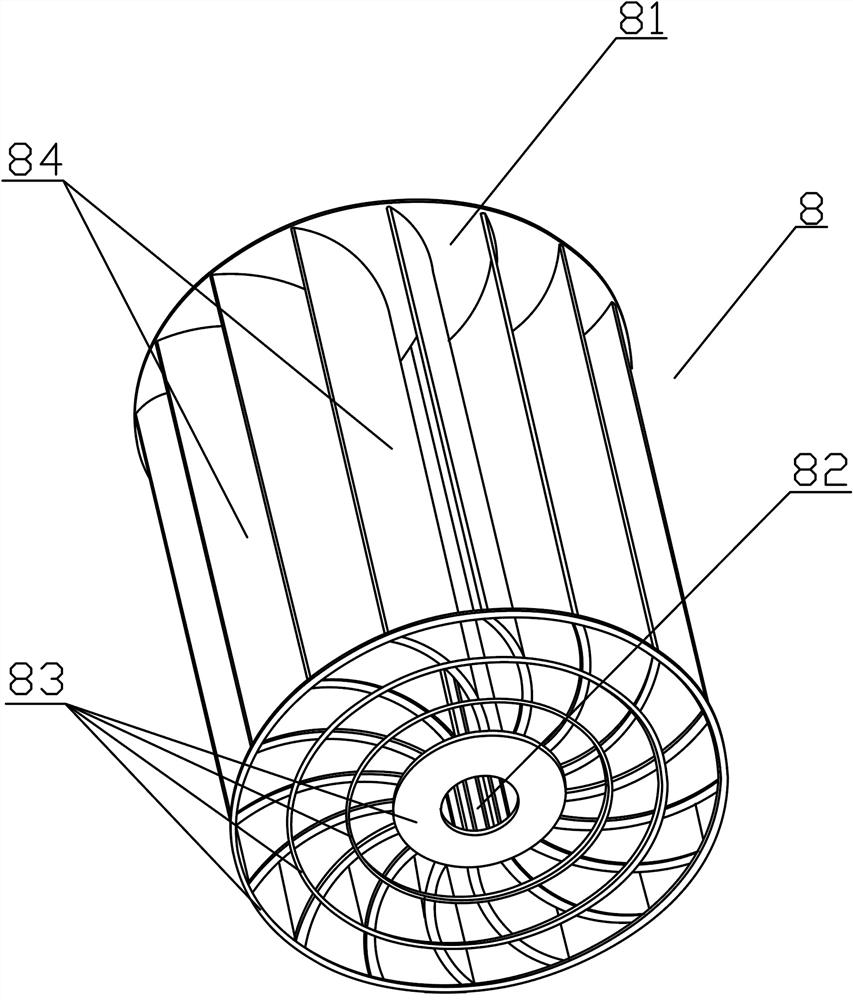

[0040] refer to Figure 1 to Figure 2 As shown in the present invention:

[0041] An inner and outer cyclone reverse split-flow air dust removal device, comprising a shell 1 with a cylindrical structure as a whole, the cylindrical shell 1 can be divided into interconnected ones in order from bottom to top in the axial direction of the cylindrical shell 1 , the air inlet dust collecting section 11 located in the lower part of the shell 1 , the cyclone reverse splitting section 12 located in the middle of the shell 1 , and the exhaust section 13 located in the upper part of the shell 1 .

[0042] Specifically, the air intake and dust collection section 11 includes an air intake duct 2 axially disposed at the middle of the bottom surface of the housing 1 and a dust collection box 3 disposed outside the air intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com