Extruding-expanding device and method for pile foundation

A technology of extruding and expanding device and pile foundation, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of soil slump, poor effect of extruding soil, affecting the bearing capacity of bearing disk piles, etc. The effect of increasing the bearing capacity of pile foundation and reducing soil collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

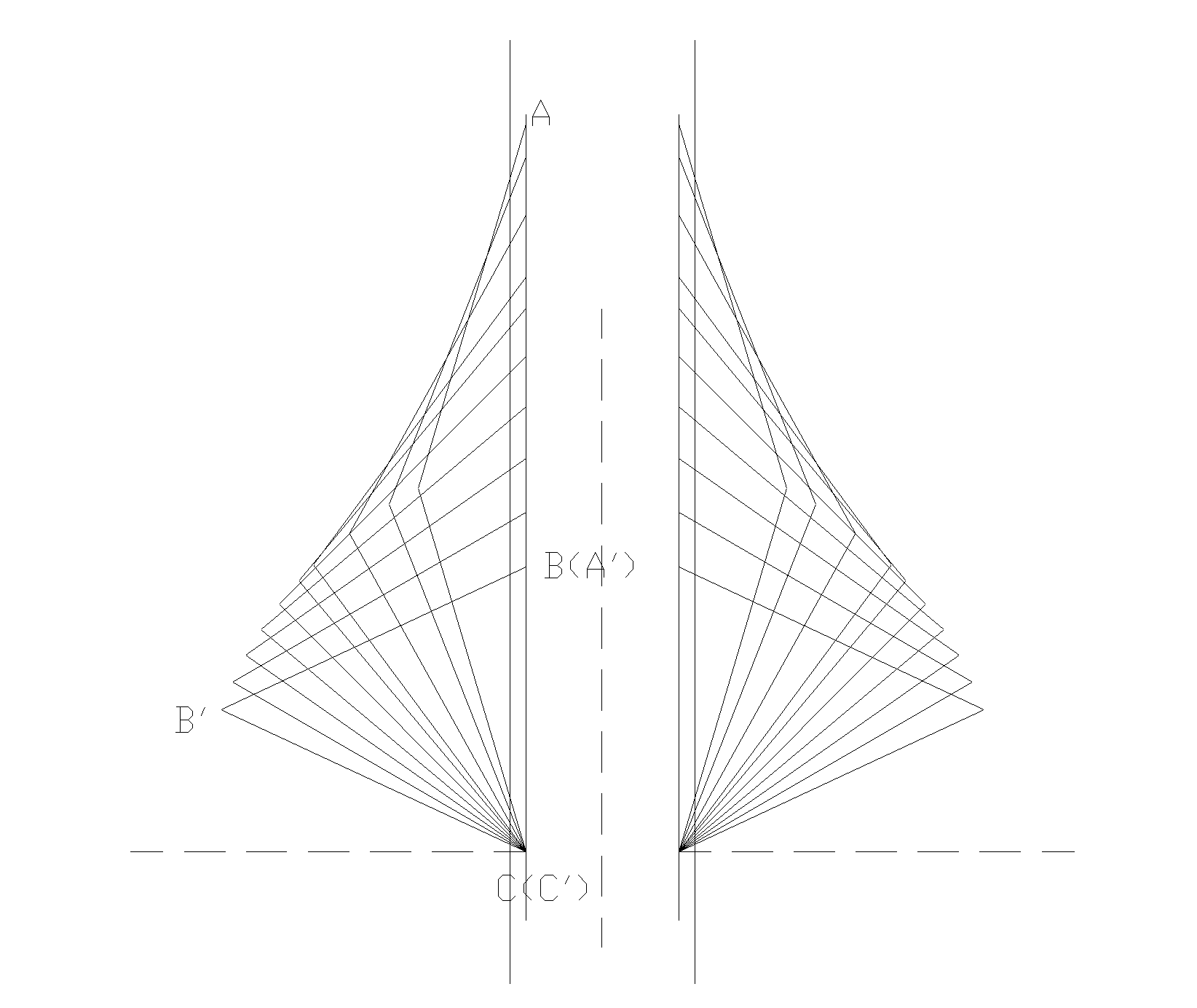

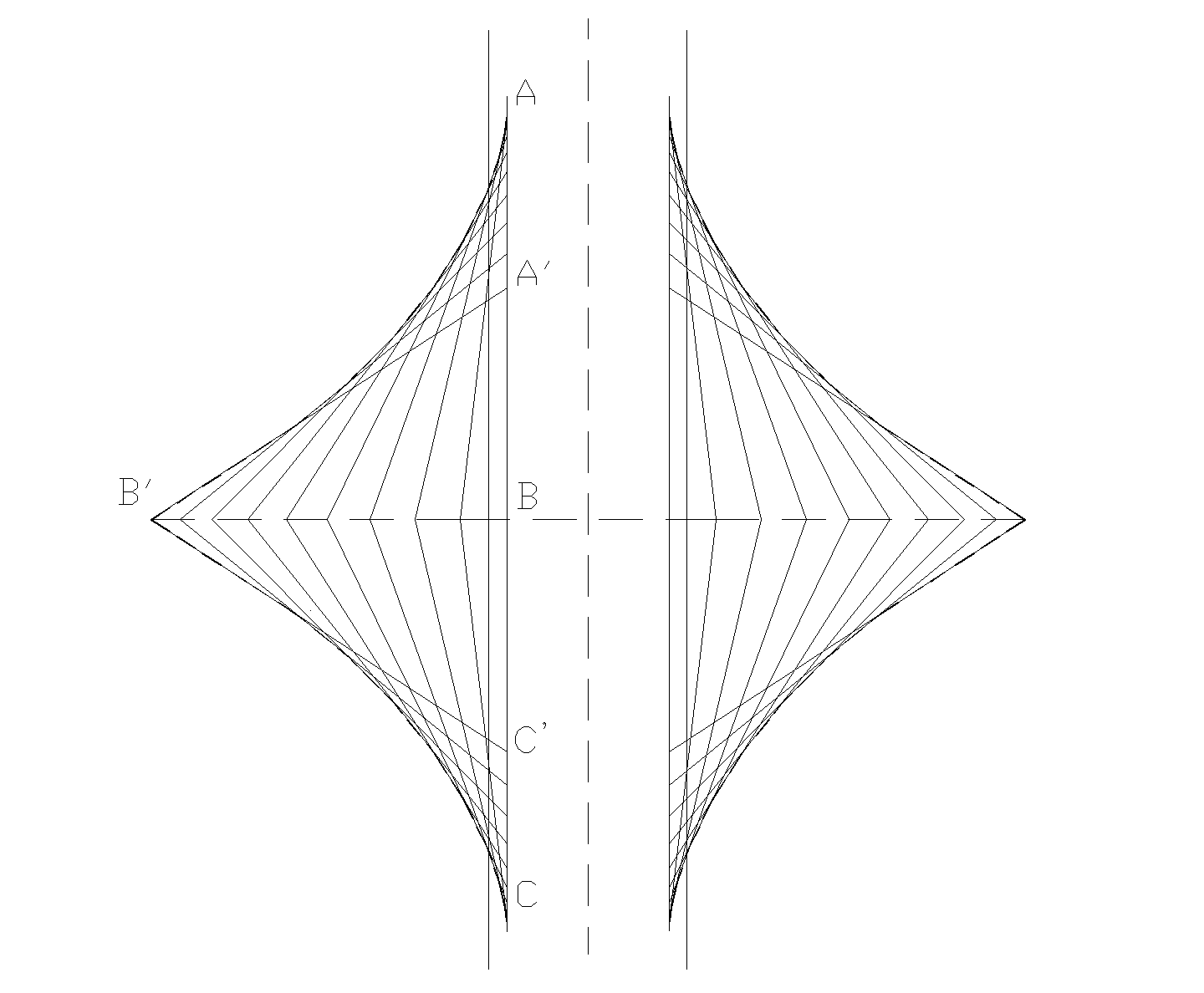

Image

Examples

Embodiment Construction

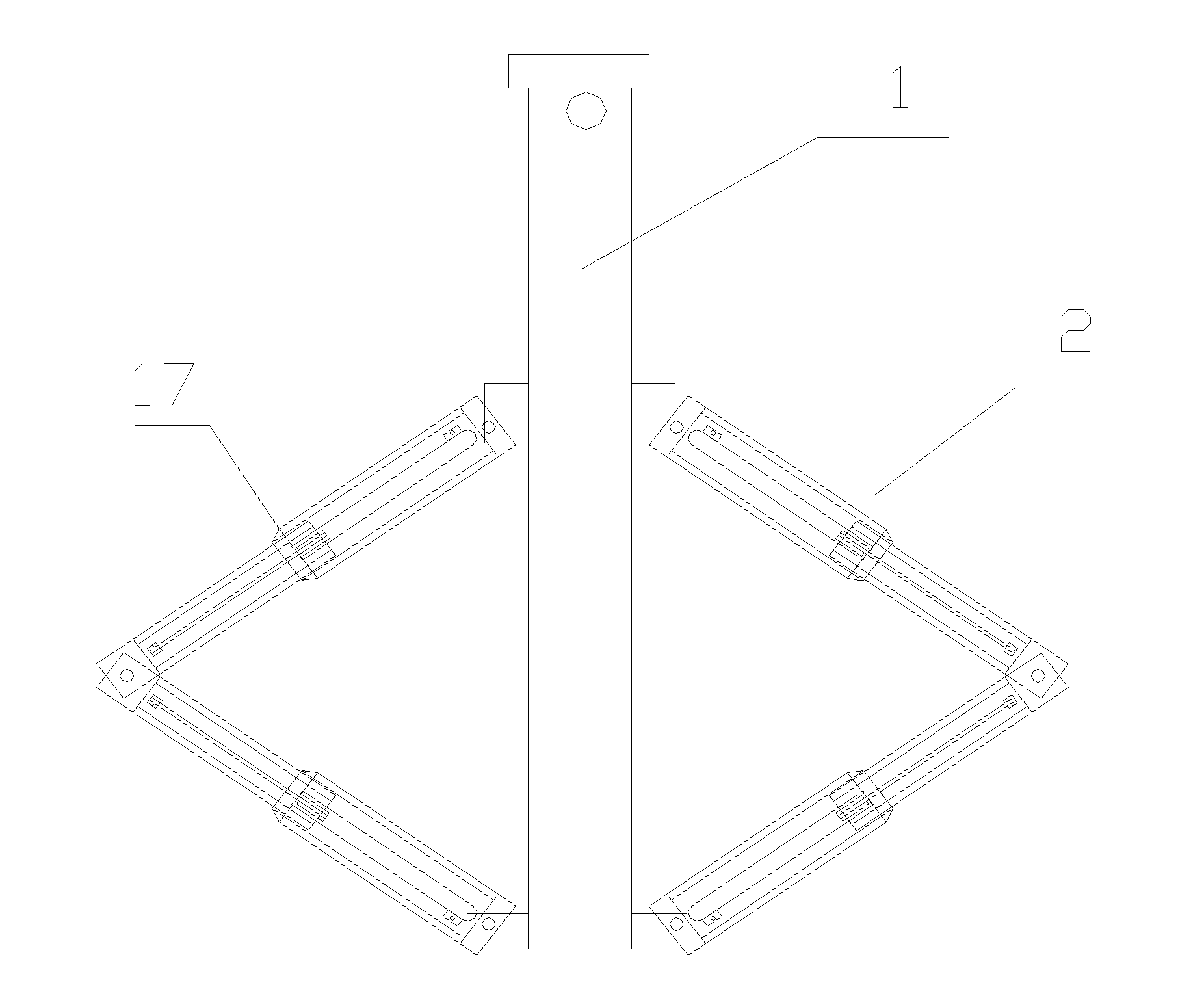

[0046] A kind of pile foundation that the present invention relates to expands device, and its preferred embodiment is as follows:

[0047] first implementation

[0048] see image 3 as well as Figure 4.1~4.4, the device comprises a receiving device 1 and an extruding and expanding arm 2 connected to the receiving device 1; the receiving device 1 of the present invention can adopt the structure of the existing receiving device 1; and the extruding and expanding arm 2 of the present invention includes a telescopic expanding arm 17 ; wherein the telescopic expansion arm 17 includes a first arm 3 and a second arm 4; the second arm is socketed in the first arm and the first arm 3 and the second arm 4 are socketed by a hydraulic cylinder, which is driven by the hydraulic cylinder to realize Telescopic, when the second arm 4 is hinged with the receiving device 1, the first arm 3 can be stretched along the outer wall of the second arm 4; or when the first arm 3 is hinged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com