Cloth ironing equipment for garment production

A technology for ironing equipment and cloth, applied in the field of garment production, can solve problems such as affecting the ironing effect and re-wrinkling of the cloth, and achieves the effects of convenient operation, reduced friction, and convenient pressing treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

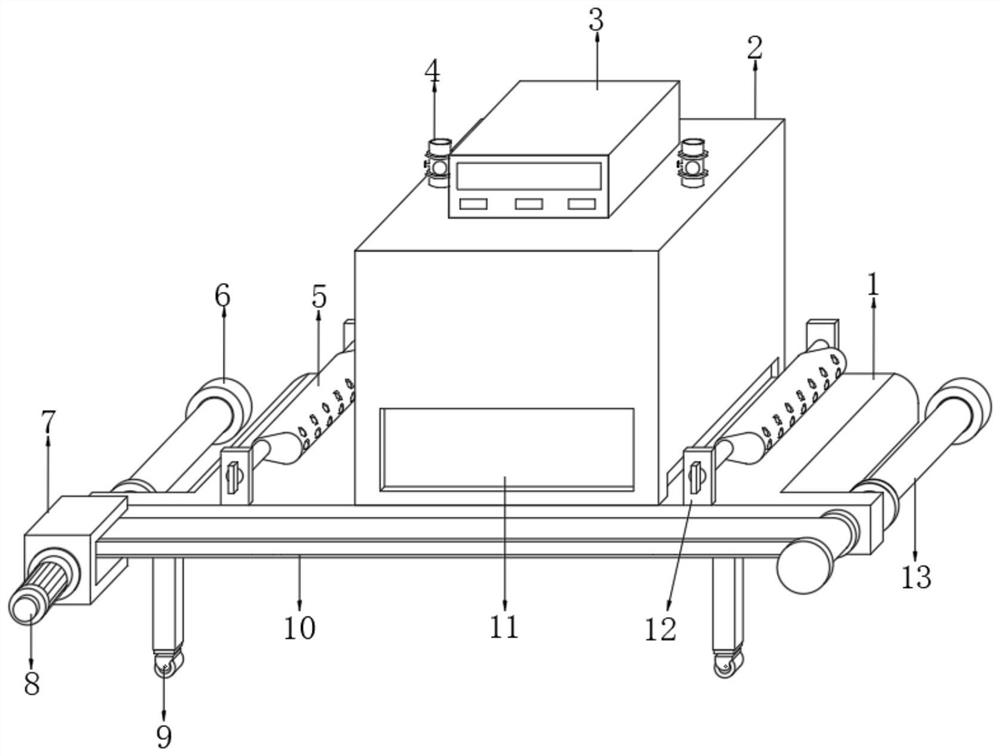

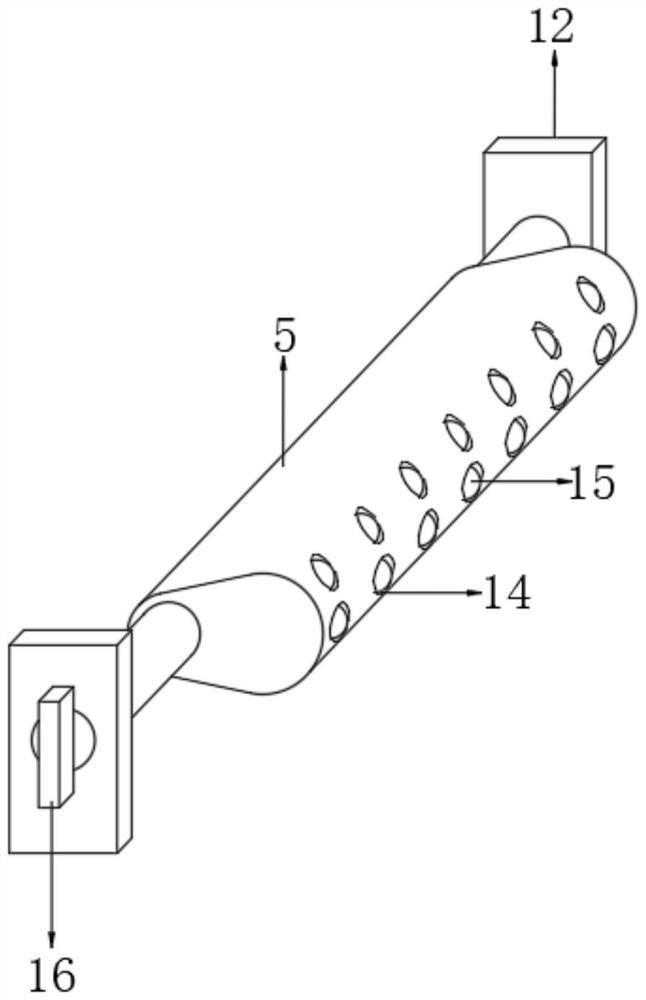

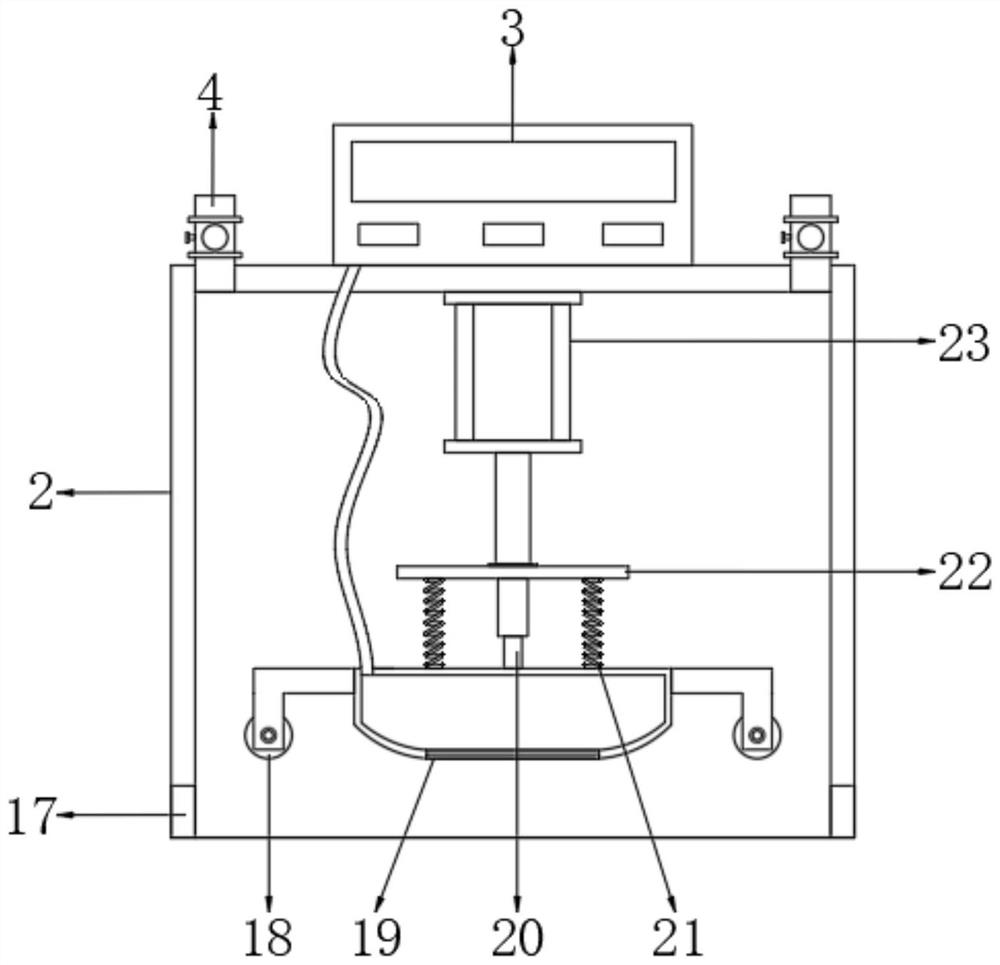

[0030] refer to Figure 1-4 , a cloth ironing device for garment production, comprising a support platform 1, installation grooves are opened on both sides of the top of the support platform 1, and a fixed rod 13 is connected to the inner wall of one side of the installation groove through bearing rotation, and the support platform 1- One end of the side outer wall is connected with a mounting frame 7 by bolts, and one side of the mounting frame 7 is connected with a motor 8 by bolts, and one end of one of the fixed rods 13 is welded with a connecting shaft passing through the support table 1, and the outer wall of the connecting shaft is connected to the motor. 8 is provided with a transmission assembly 10 between the outer walls of the output shaft, the middle position of the top of the support table 1 is connected with the ironing box 2 by bolts, and the bottoms of both sides of the ironing box 2 are provided with inlets and outlets 17, and the top of the support table 1 Th...

Embodiment 2

[0040] refer to Figure 5 , a cloth ironing device for clothing production. Compared with Embodiment 1, this embodiment replaces the threaded hole 25 and the threaded rod 26 with an insertion hole 29 and an insertion rod 28 in turn, and the insertion rod 28 is inserted into the insertion hole 29 Inside, the inserting rod 28 is made up of the first cross bar and the second cross bar, the top side of the second cross bar has a limiting groove, and one side of the second cross bar is welded with a limiting groove inserted in the limiting groove. A second spring 27 is fixedly connected between one end outer wall of the insertion rod 28 and one side inner wall of the insertion hole 29 .

[0041] Working principle: When fixing the cloth take-up reel, pull out the limit cylinder 6 directly from the fixing rod, so that the limit frame is out of the limit slot, and insert the cloth take-up reel on the fix rod 13, so that The limit frame is inserted in the limit groove, and the limit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com