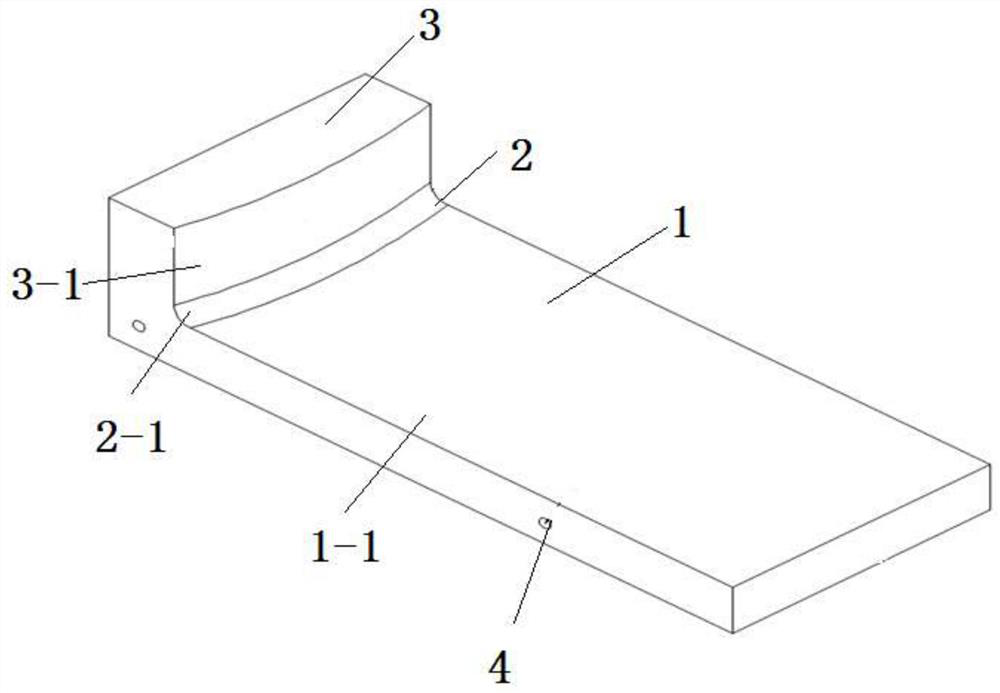

Forging mold for near-net-formed titanium strip plate blank and free forging machining method

A near-net shape and processing method technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of low comprehensive yield of titanium strips, changes in structure and morphology, and high prices of titanium strips , to achieve the effect of increasing the yield, changing the shape of the structure, and shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A free forging processing method for a near-net-shaped titanium strip slab, specifically implemented according to the following steps:

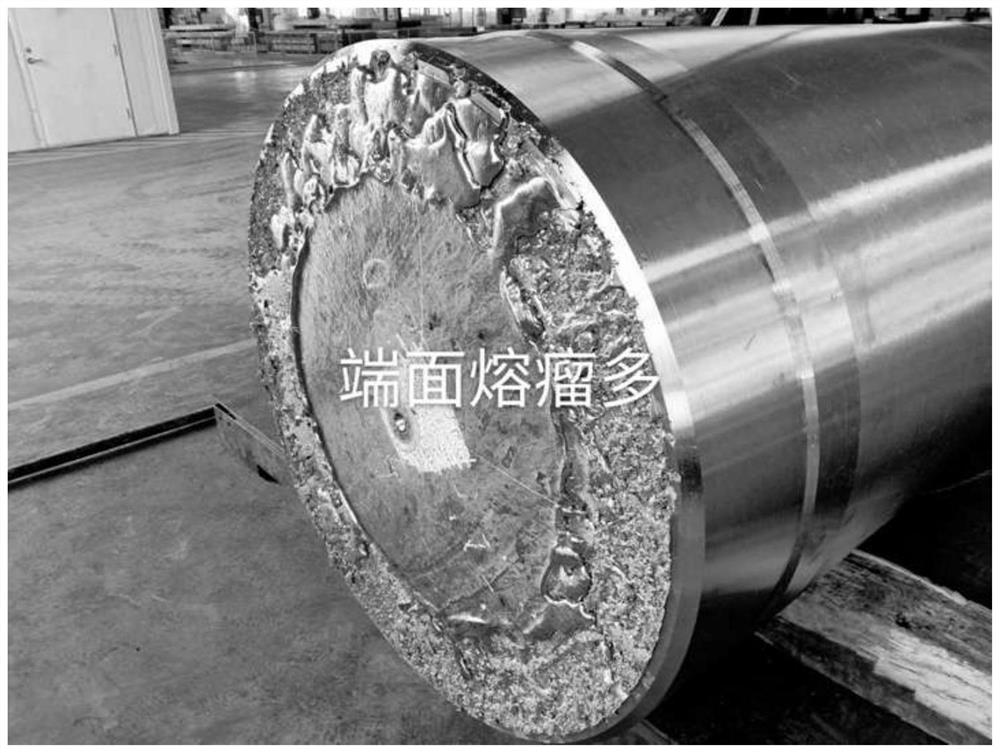

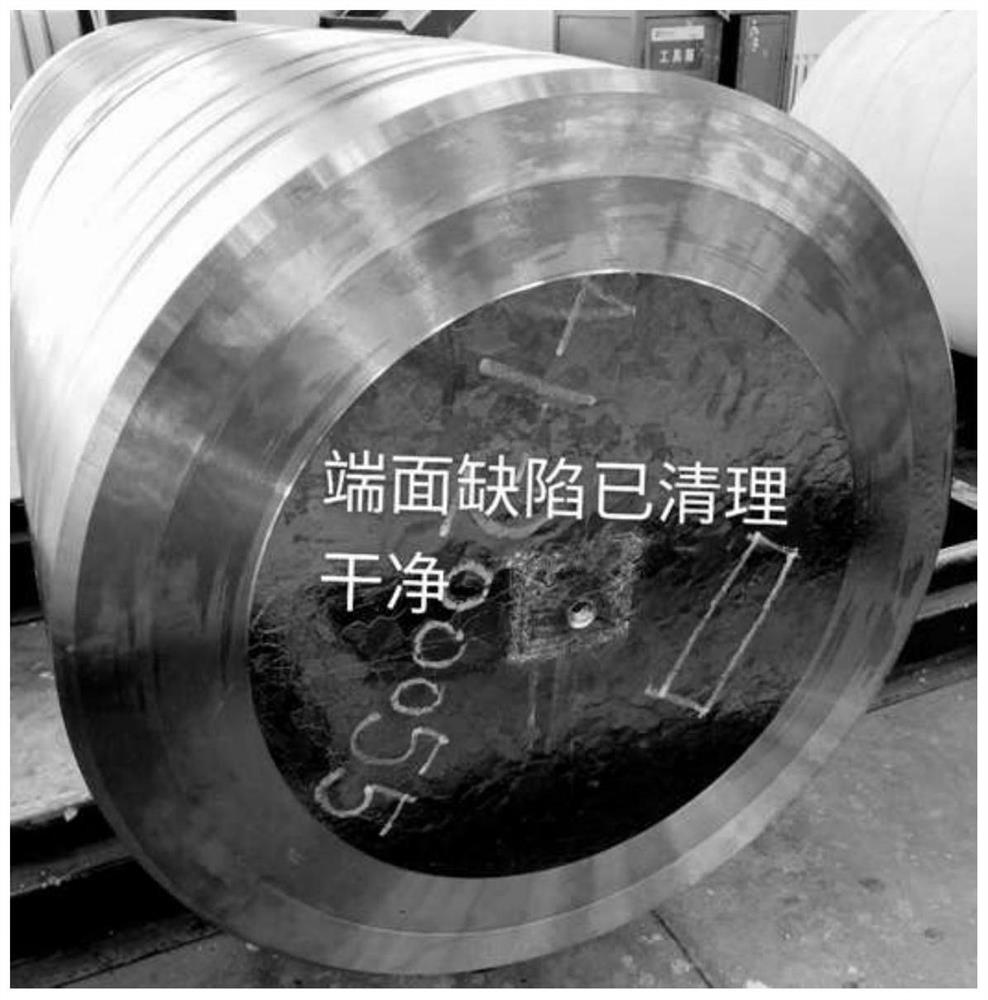

[0074] Step (1) Ingot preparation: The titanium and titanium alloy ingots smelted in a vacuum consumable electric arc furnace for the second time are peeled along the circumferential direction on a heavy-duty lathe. Then remove the defects on the head and bottom of the ingot (especially the coral-like defects at the position of the riser of the ingot). Next, fillet the head and tail of the ingot.

[0075] In step (1), the titanium and titanium alloy ingots used are secondary smelted by vacuum consumable arc method, the grade is TA1, the diameter is Φ1020mm, and the weight is 8995kg.

[0076] In step (1), the ingot head and tail fillet radius R=15mm.

[0077] Step (2) Ingot heating: firstly from room temperature to 800°C, heating time 150 minutes; then heat preservation at 800°C, heat preservation time 180 minutes; then heat up to 100...

Embodiment 2

[0084] The titanium and titanium alloy ingots used in the step (1) are secondary smelted by the vacuum consumable arc method, the grade is TA1, the diameter is Φ1020mm, and the weight is 8960kg. The remaining forging methods and process parameters are the same as in Example 1, and the size of the obtained finished product is: 220 (thickness) × 1280 (width) × 6940 (length) mm.

Embodiment 3

[0086] The titanium and titanium alloy ingots used in the step (1) are secondary smelted by the vacuum consumable arc method, the grade is TA1, the diameter is Φ1020mm, and the weight is 8990kg. The other forging methods and process parameters are the same as in Example 1, and the size of the obtained finished product is: 220 (thickness) × 1280 (width) × 6970 (length) mm.

[0087] Embodiment 1-3 effect verification:

[0088] After carrying out effect verification to three titanium belt slabs that embodiment 1-3 obtains, the data are as follows:

[0089]

[0090] It can be seen from the verification data that the finished product rate of the three ingots after forging has increased by 10.42% compared with 88% before the implementation, reaching 98.42%. Based on an annual output of 20,000 tons of titanium strip products of this specification, the current market price is 85,000 yuan / t, and the residual material is 30,000 yuan / t, then: 20000×10.42%×(8.5-3.0)=114.62 million yua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com