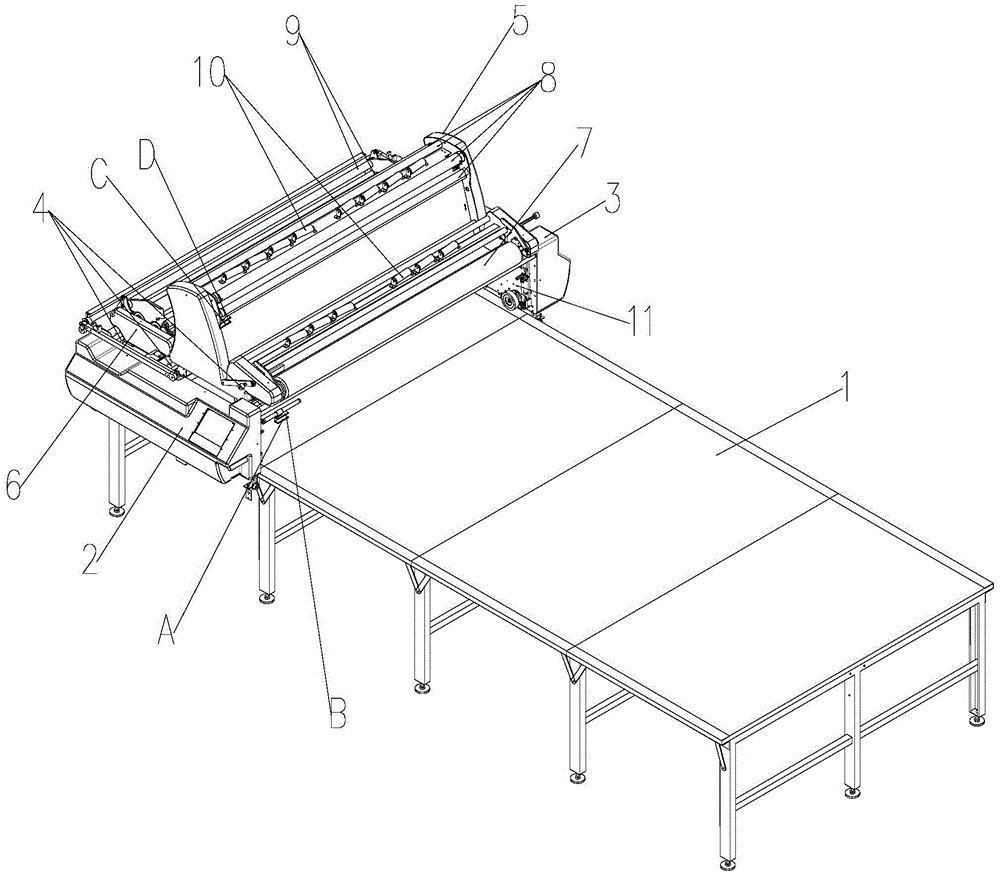

Two-stage edge aligning system of full-automatic cloth laying machine

A cloth spreading machine, fully automatic technology, applied in the direction of spreading thin soft materials, thin material handling, transportation and packaging, etc., can solve problems such as uneven cloth edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

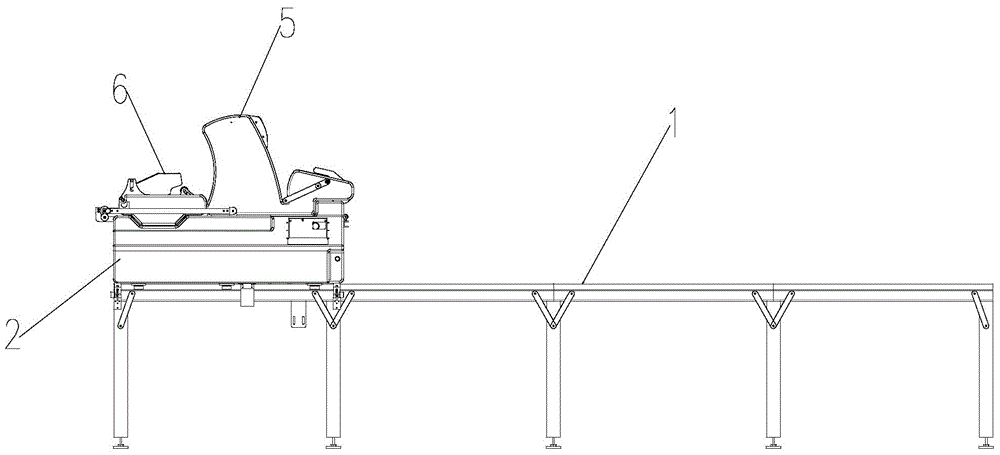

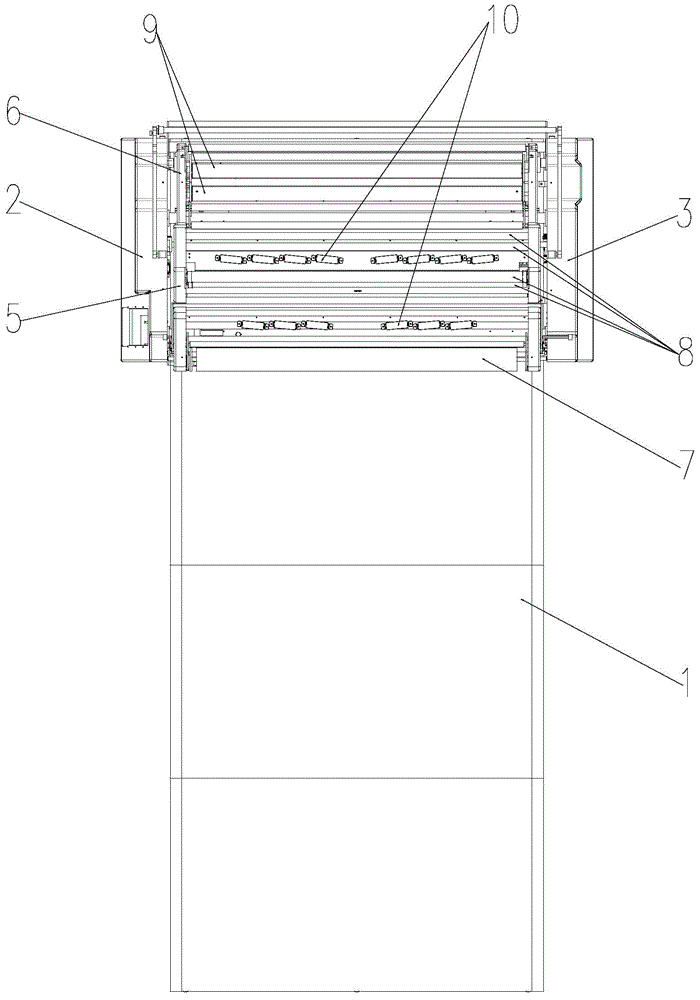

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0014] see Figure 1 to Figure 4 , the double-stage side-to-side system of the fully automatic spreading machine of the present invention comprises a platen 1, a left side plate 2 and a right side plate 3 respectively installed on both sides of the upper rear end of the platen 1 through the walking part 11 of the whole machine, fixed on the A plurality of crossbeams 4 between the side plates 2, 3, a front cradle 5 and a rear cradle 6 mounted on the crossbeam 4 that can move left and right separately, and cloth feed rollers 7 and multiple cloth feed rollers installed on the front and rear ends of the front cradle 5, respectively. A spreading roller 8, two primary side-to-side sensors C, D for controlling the left and right movement of the rear cradle 6 are fixedly connected to the left side of the front cradle 5, and the two primary side-to-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com