Energy-store state-liquid driving device of secondary flow-regulation coupling hydraulic energy accumulator

A hydraulic accumulator and secondary adjustment technology, which is applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., to achieve the effect of reducing energy consumption and reducing installed power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

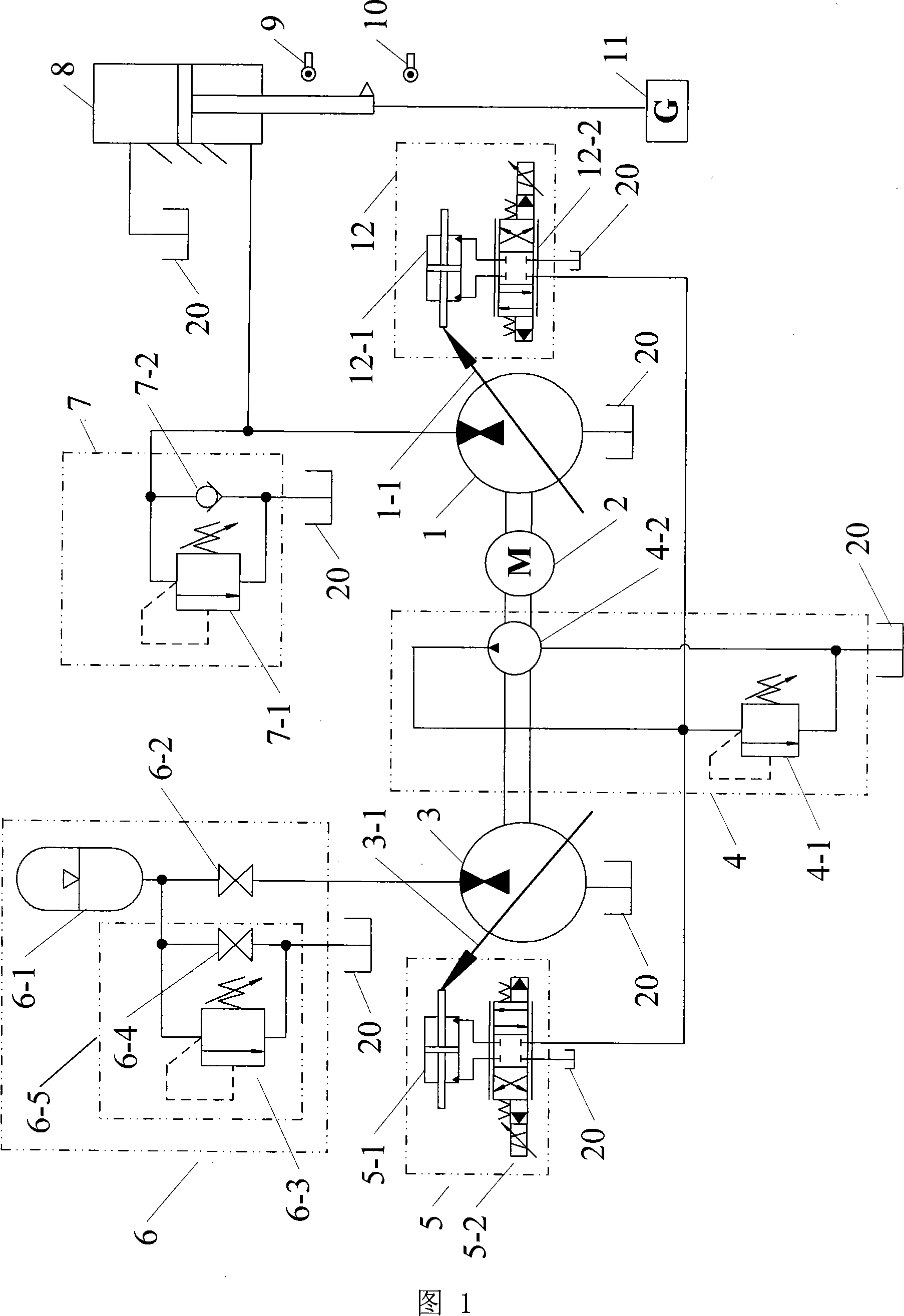

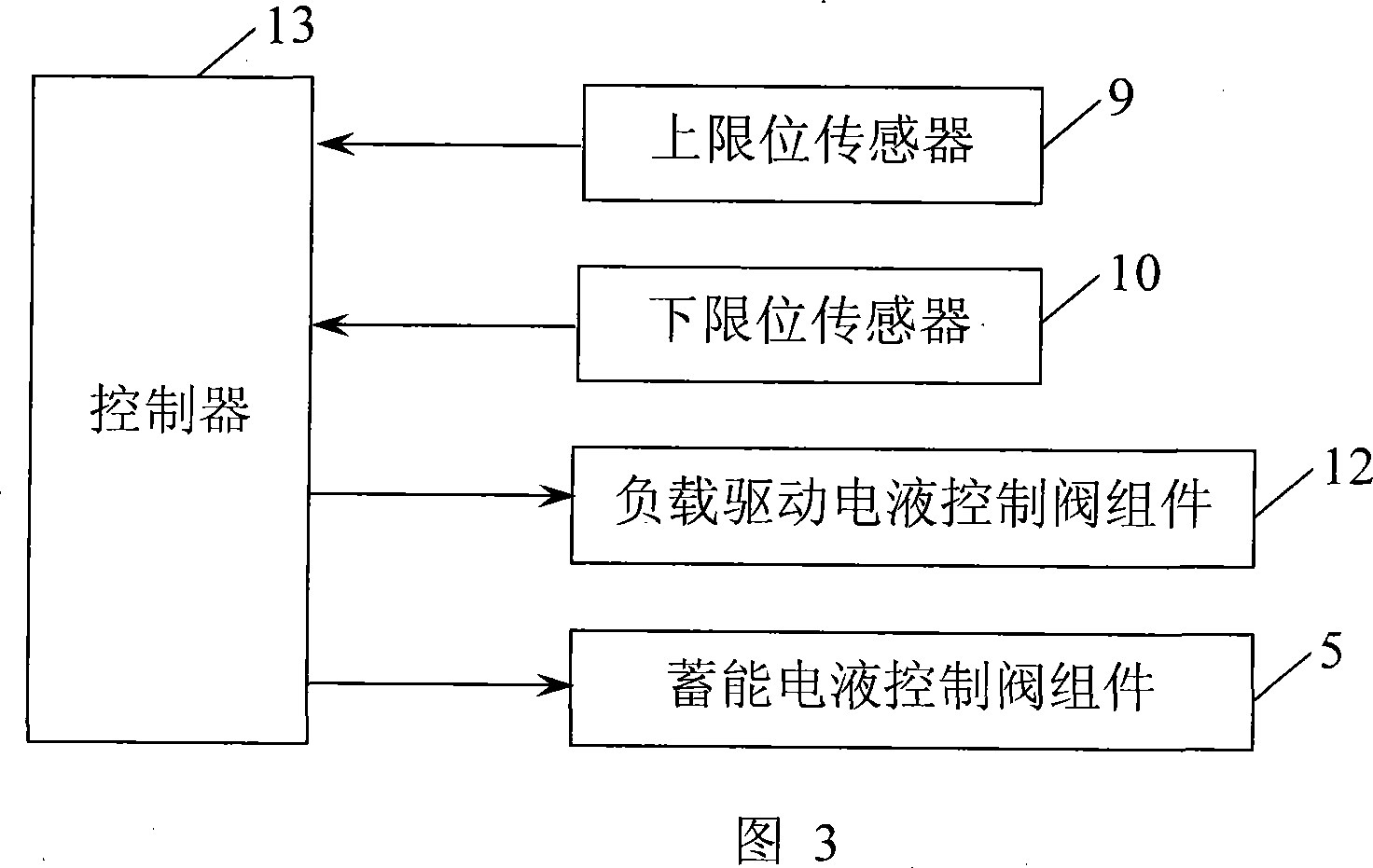

[0009] Specific implementation mode 1: The hydraulic accumulator energy storage hydrostatic transmission device for secondary flow adjustment in this embodiment is driven by a load to drive a hydraulic pump / motor 1, an electric motor 2, an energy storage hydraulic pump / motor 3, and a control oil circuit assembly 4 , energy storage electro-hydraulic control valve assembly 5, hydraulic accumulator assembly 6, hydraulic cylinder safety valve assembly 7, hydraulic cylinder 8, upper limit sensor 9, lower limit sensor 10, load-driven electro-hydraulic control valve assembly 12 and controller 13 composition.

[0010] The piston rod of the hydraulic cylinder 8 is connected to an external heavy load 11, and an upper limit sensor 9 and a lower limit sensor 10 are fixed on the side of the piston rod of the hydraulic cylinder 8, and the upper limit sensor 9 and the lower limit sensor 10 The distance between them is equal to the working stroke of the hydraulic cylinder 8, and the electrica...

specific Embodiment approach 2

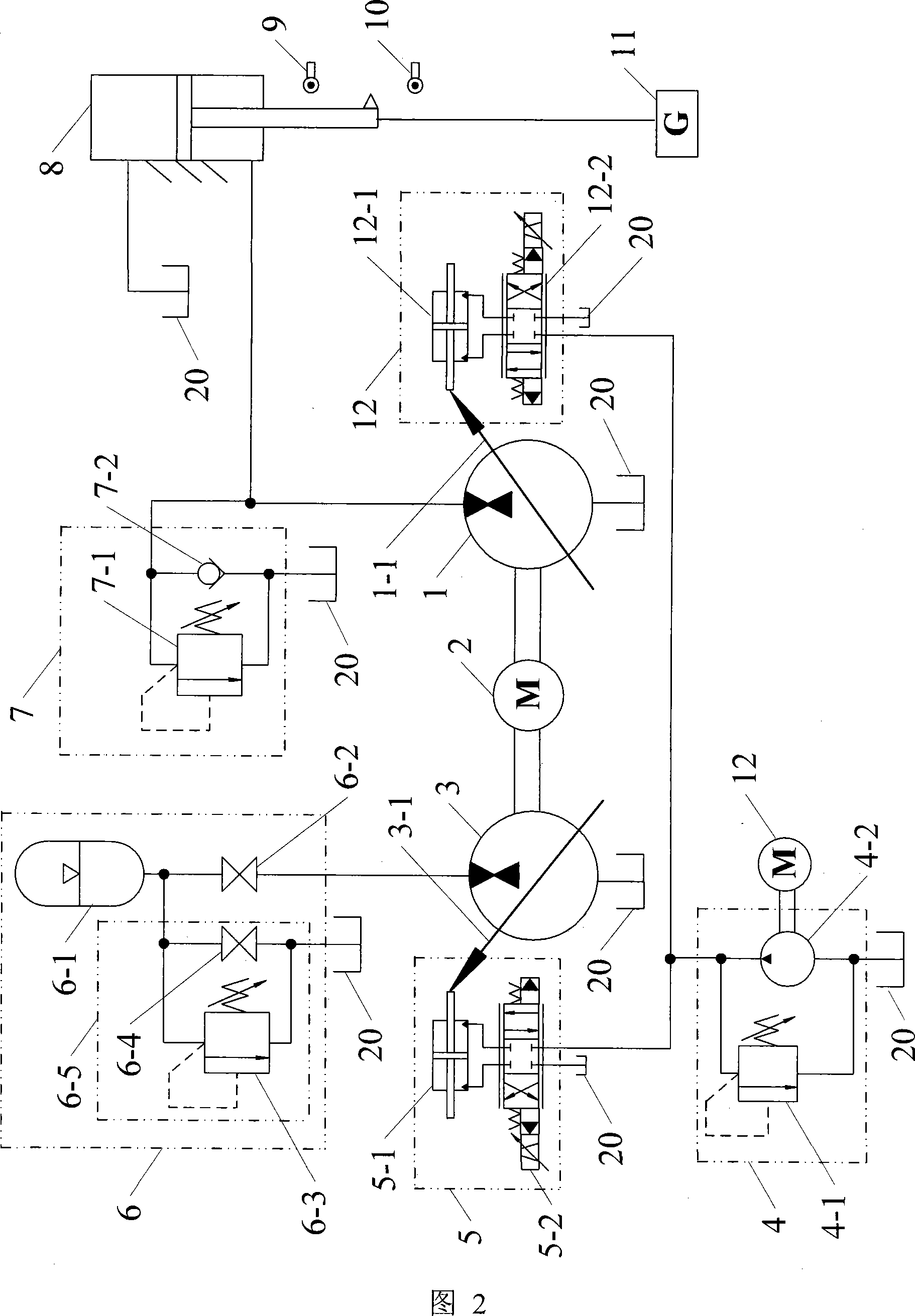

[0023] Embodiment 2: The difference between this embodiment and the hydrostatic transmission device for secondary flow regulation coupled hydraulic accumulator energy storage described in Embodiment 1 is that it also includes a control oil circuit driving motor 14, a control oil circuit assembly The transmission shaft of the control hydraulic pump 4-2 in 4 is not connected with the output shaft of the motor 2, but is fixedly connected with the output shaft of the control oil passage drive motor 14.

[0024] The control oil circuit assembly 4 of this embodiment works independently and is not affected by the working condition of the transmission motor 2 .

specific Embodiment approach 3

[0025] Specific Embodiment 3: The difference between this embodiment and the secondary regulating flow coupling hydraulic accumulator energy storage hydrostatic transmission described in Embodiment 1 or 2 is that it also includes a plurality of accumulator assemblies 6, so The oil delivery ports of the plurality of hydraulic accumulator assemblies are connected in parallel and communicate with the oil delivery ports of the accumulator hydraulic pump / motor 3.

[0026] In this embodiment, multiple hydraulic accumulator assemblies 6 are used in parallel, and multiple hydraulic accumulator assemblies can be configured according to the actual site conditions and the volume and output pressure of the selected accumulator, which improves the versatility of the system .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com