Composite capacitor-resistor type full-flexibility touch and pressure sensor

A capacitive resistance, composite technology, applied in the field of sensing, can solve the problem that the sensor cannot detect both tactile force and pressure force, and achieve the effect of improving resolution and sensitivity, realizing bending deformation, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

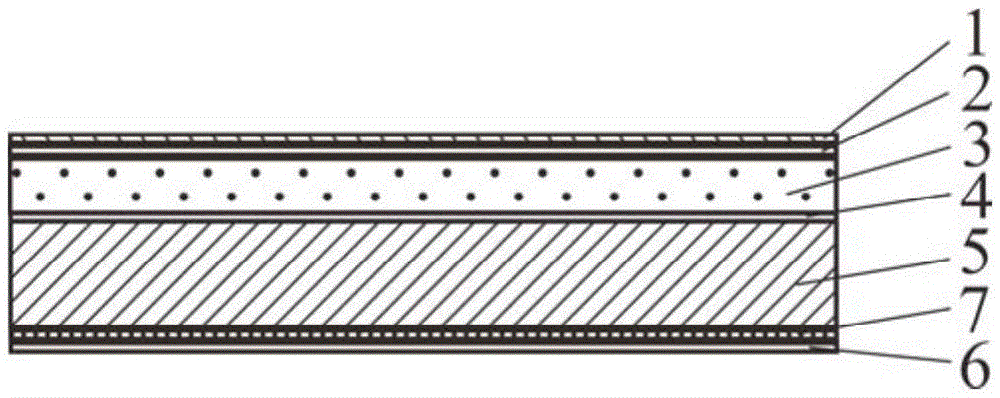

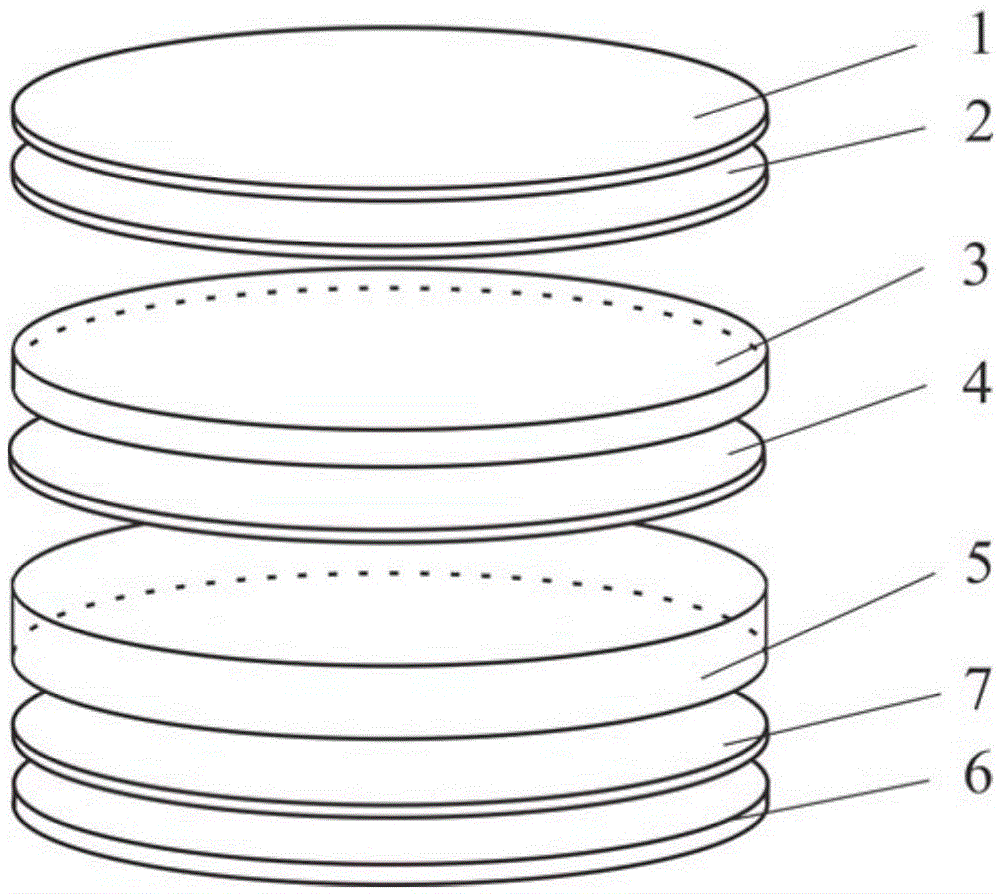

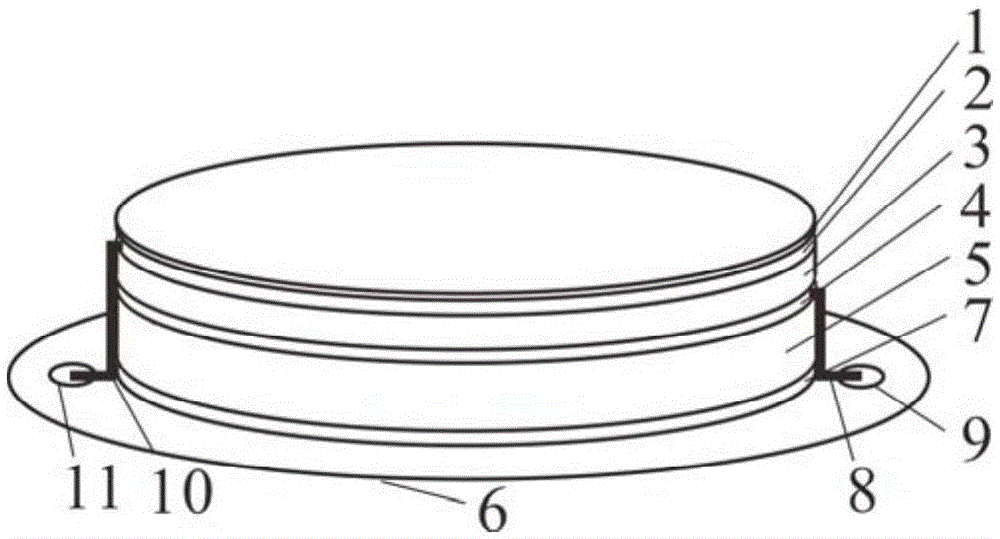

[0031] Such as figure 1 , figure 2 As shown, the fully flexible touch pressure sensor based on the capacitance-resistance composite type in this embodiment has a multi-layer upper and lower structure, and a lower electrode 7 is arranged on the upper surface of the flexible substrate 6, and a resistive layer 5 is arranged above the lower electrode 7. A common electrode 4 is provided above the resistance layer 5, a capacitive layer 3 is provided above the common electrode 4, an upper electrode 2 is provided above the capacitive layer 3, and a flexible protective layer 1 is provided above the upper electrode 2;

[0032] Wherein the capacitance layer 3 is located above the resistance layer 5, the thickness of the capacitance layer 3 is 1 mm, the thickness of the resistance layer 5 is 2 mm, the height of the entire sensor is 3.5 mm, and the diameter is 8 mm;

[0033] The resistance layer 5 uses carbon nanotubes / carbon black filled silicone rubber as the sensitive material, adopts...

Embodiment 2

[0054] In order to explore the influence of different sensitive materials on the performance of the sensor, in this embodiment, the sensitive material of the capacitance layer 3 in the embodiment 1 is replaced with PDMS, and the rest remain the same as in the embodiment 1. The capacitance-stress relationship curve of the gained fully flexible touch pressure sensor is as follows Figure 9 As shown, compared with the capacitive layer made of silicone rubber as the sensitive material, the capacitive layer made of PDMS has higher sensitivity, but the resolution is only 0.5N.

Embodiment 3

[0056] In order to explore the influence of different sensitive materials on the performance of the sensor, in this embodiment, the sensitive material of the resistance layer 5 in the embodiment 1 is replaced by a carbon nanotube / carbon black filled silicone rubber with a mass fraction of 6%, and the rest remain the same as in the embodiment 1. . The resistance-stress relationship curve of the gained fully flexible tactile pressure sensor is as follows Figure 10 As shown, compared with the carbon nanotube / carbon black filled silicone rubber with a mass fraction of 5% as a resistive layer, the carbon nanotube / carbon black filled silicone rubber with a mass fraction of 6% has a higher sensitivity , but it can only detect a maximum stress of 80N (1250kPa).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com