Single working station linen unfolding and conveying device

A conveying device and a single-station technology, which is applied in the directions of transportation and packaging, winding strips, and spreading thin soft materials, etc., and can solve problems such as poor surface flatness, poor linen flatness, and high labor intensity for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

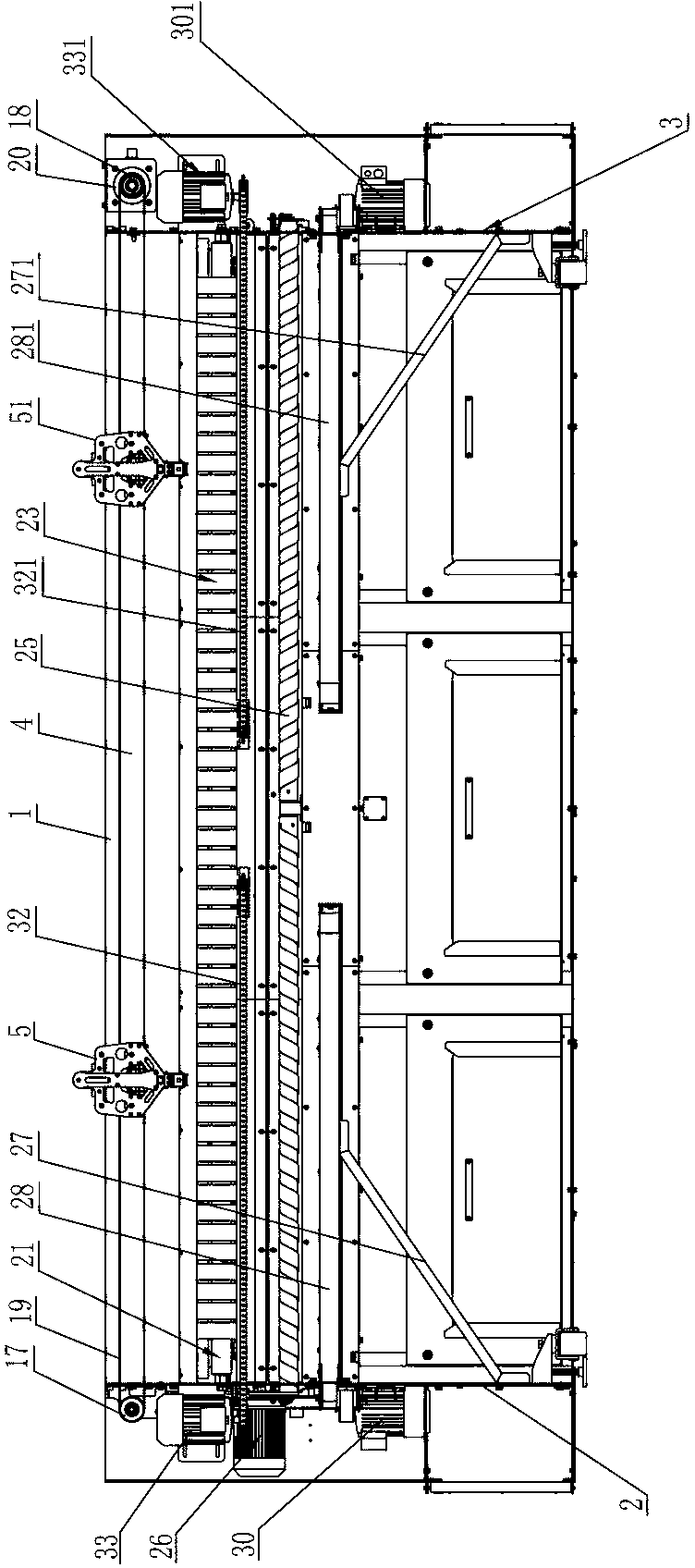

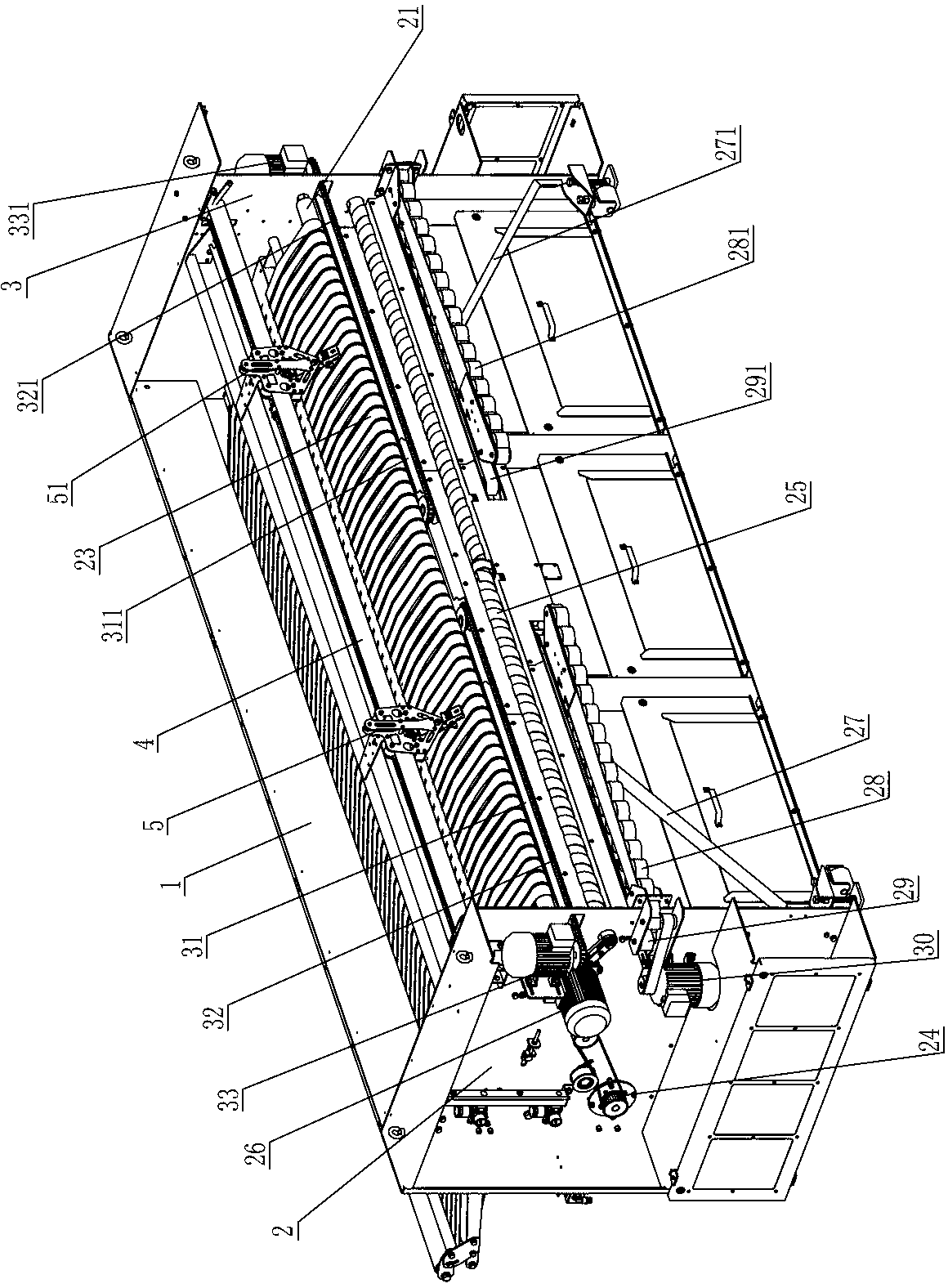

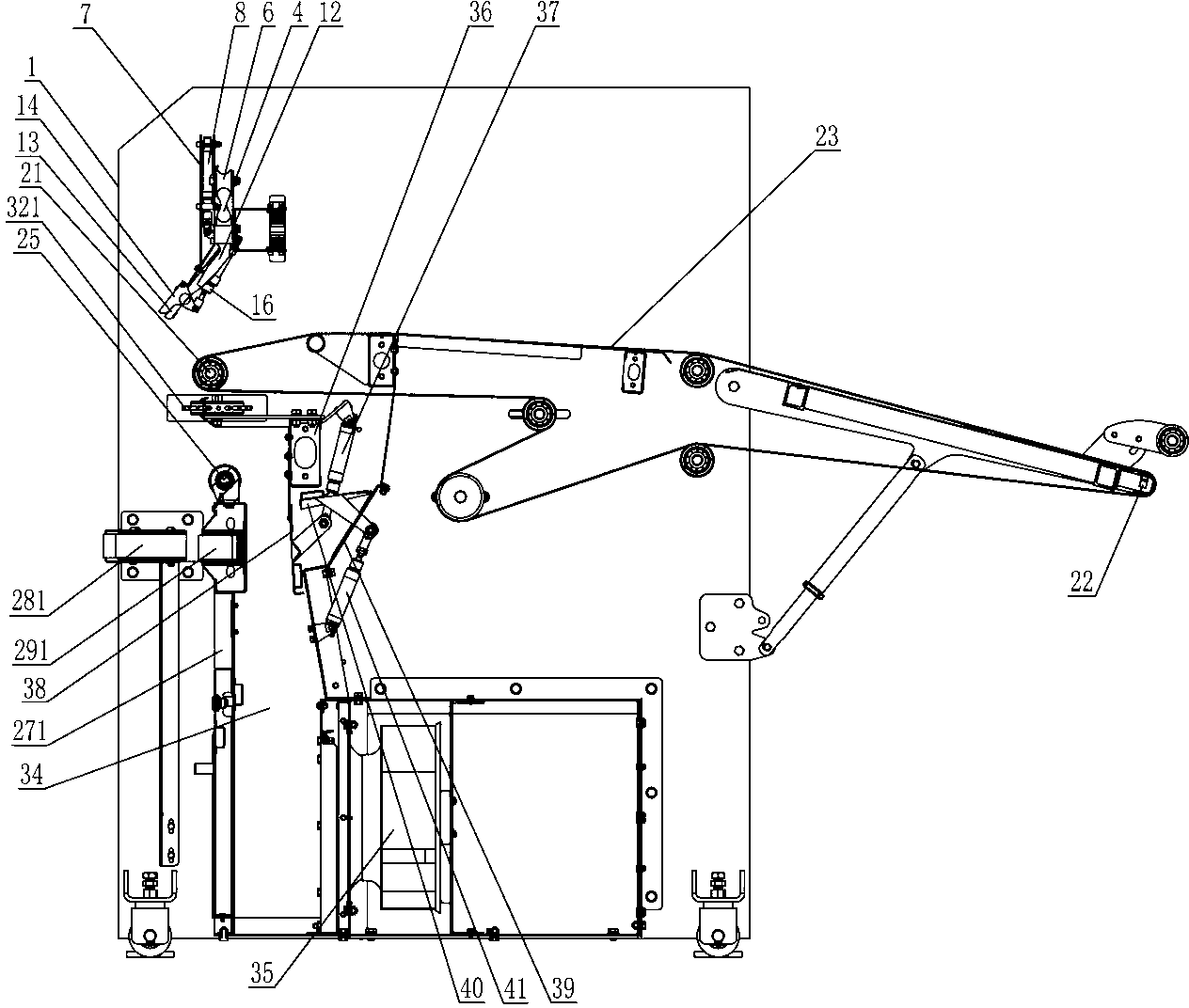

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5As shown, the single-station spread conveying device includes: a frame 1, a track 4 is fixed between the left side panel 2 and the right side panel 3 above the front end of the frame 1, and a rail 4 is movable on the track 4 There are two spread manipulators 5, 51 that can clamp the linen. In this embodiment, since the structures of the spread manipulators 5 and 51 are the same, only one of the spread manipulators will be used as an example to describe its structure below. Explanation: The structure of the spread manipulator is: a movable frame 7 with a pulley 6 installed, the movable frame 7 slides on the track 4 through the pulley 6, a swing cylinder 8 is installed on the movable frame 7, and the piston rod of the swing cylinder 8 passes through The connecting block 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com