Cloth spreading machine

A cloth spreading machine and cloth pressing plate technology, which is applied in the directions of winding strips, folding thin materials, spreading thin soft materials, etc., can solve the problems of small working space, high cost, high labor intensity, etc., and achieve a simple structure. , low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

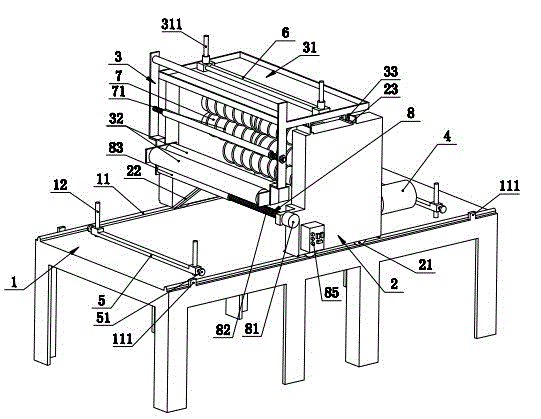

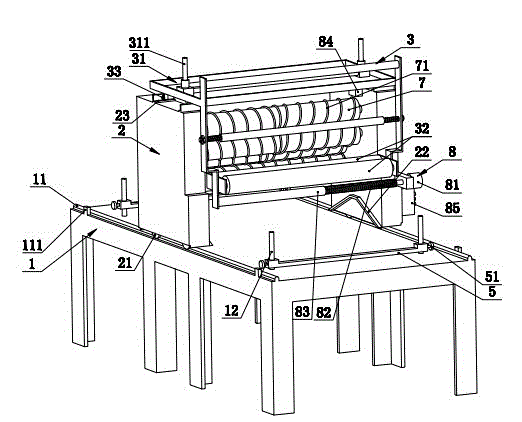

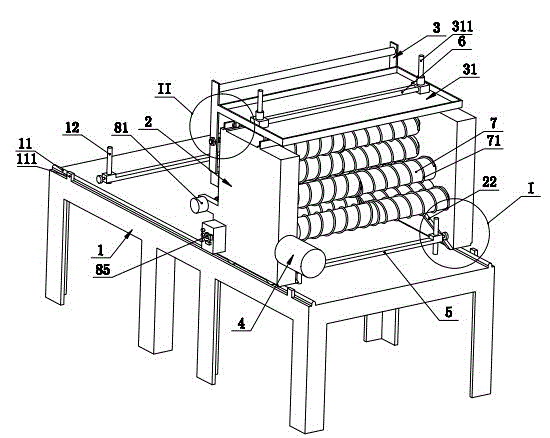

[0021] Such as figure 1 , 2 , 3, 4, and 5 show a cloth spreading machine, including a workbench 1, a moving frame 2, a feeding frame 3 and a three-phase motor 4, and the X-axis direction of the workbench 1 is provided with two parallel Guide rails 11, the moving frame 2 is correspondingly provided with pulleys 21 that form a linear sliding fit with the two parallel guide rails 11 on the workbench 1 in the X-axis direction, and the parallel guide rails 11 on the workbench 1 The left and right ends in the X-axis direction are also symmetrically provided with baffles 111 that limit the left and right sliding distance of the pulley 21 on the mobile frame 2 . The left and right ends of the workbench 1 in the X-axis direction are also symmetrically provided with workbench bosses 12 whose central axis is in the Z-axis direction, and the workbench bosses 12 at the left and right ends of the workbench 1 are fitted with a The workbench boss 12 is a cloth pressing plate 5 that slides u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com