Synchronous air flotation system for cloth-paved tables

A cloth spreading and air pump technology, applied in the field of spreading tables, can solve the problems of increased labor costs, power loss, energy waste, etc., and achieve the effect of convenient modification, low cost, and reduced manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

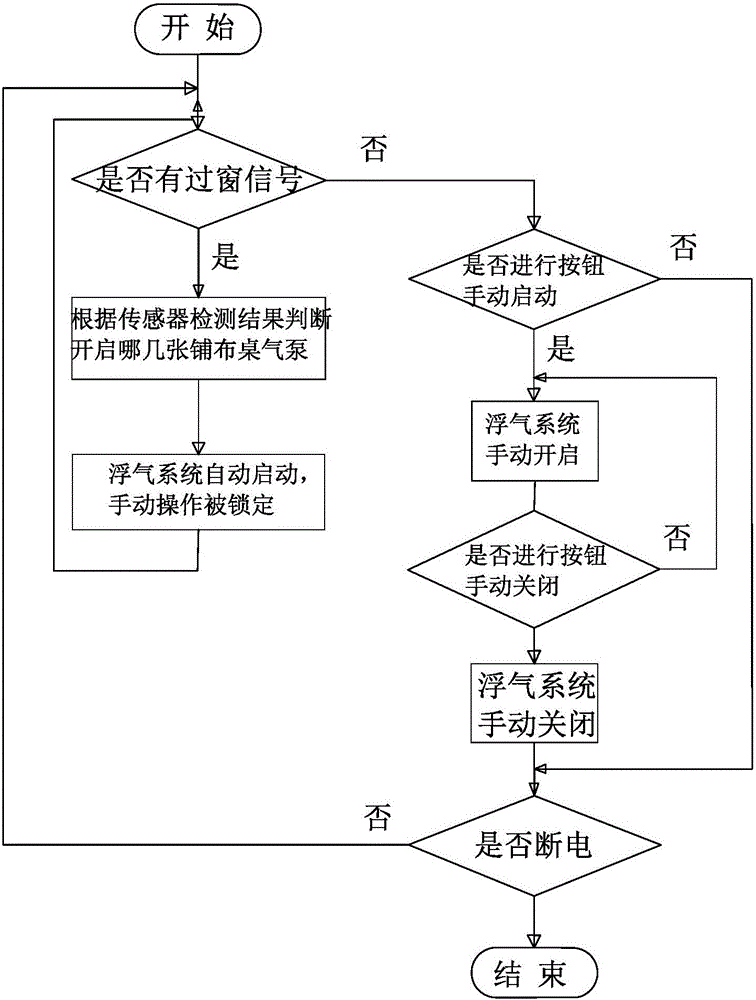

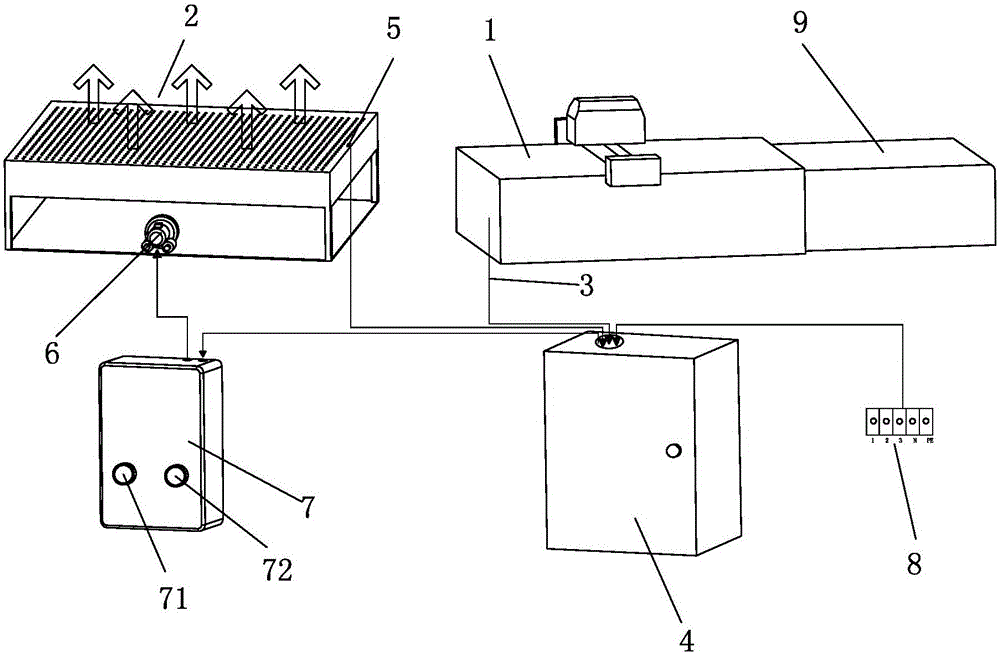

[0016] The present invention will be further described below with specific embodiment, see figure 1 -2:

[0017] A synchronous floating air system for spreading tables, including a window signal provided by a cutting bed 1, and more than one air-floating spreading table 2 arranged side by side, and one end of the cutting bed 1 is connected to a receiving platform 9 , the signal line 3 of the signal through the window is drawn from the electric control box of the cutting bed 1, and is electrically connected with the control box 4 through a plug, and an air pump 6 is arranged under each spreading table 2, and the air pump 6 is combined with the control box 4 through the window The signal controls the start and stop, and the control box 4 is electrically connected with the power supply 8 .

[0018] The control box 4 is also electrically connected with the manual button box 7, and the manual button box 7 is electrically connected with the air pump 6 to manually control the start ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com