Cloth spreading machine with manipulator cloth clamping mechanism

A technology of manipulators and cloth stretching machines, which is applied in the direction of spreading thin soft materials, sending objects, thin material processing, etc., and can solve the problems of reducing the accuracy of cloth cutting, inconsistent length of cloth spreading, and misalignment of cloth ends. To achieve the effect of high work efficiency, tidy stacking and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

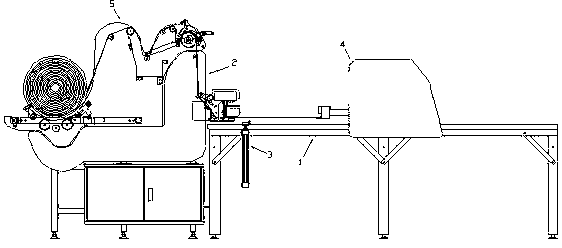

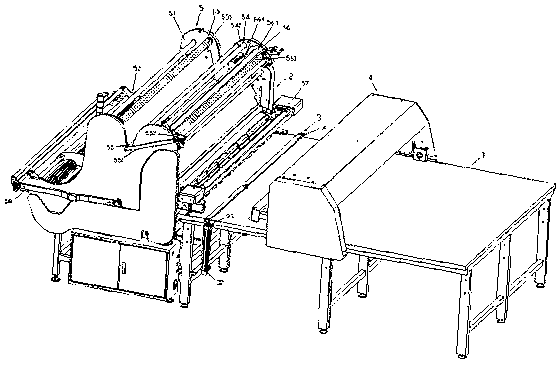

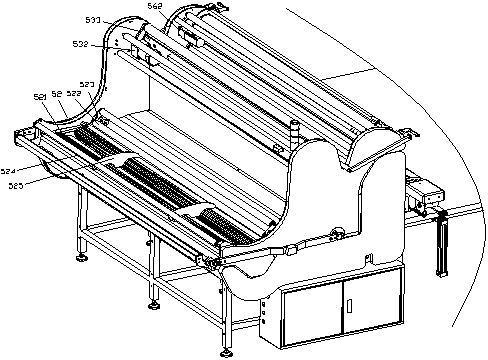

[0021] The present invention comprises bed making 1, main machine 2 and cloth pressing mechanism 3 on the top of making bed 1 and the manipulator cloth clamping mechanism 4 that slides on the making bed, and described main machine 2 is provided with a cloth spreading mechanism 5, and one side of cloth spreading mechanism 5 is provided with release Cloth mechanism 52, the other side is provided with cloth spreading mechanism 53, and cloth spreading mechanism 53 front is provided with front cloth spreading mechanism 54, and front cloth spreading mechanism 54 front is provided with cloth feeding mechanism 56, and cloth feeding mechanism 56 below is provided with cutting machine. Cloth device 57, the cloth enters from the loosening cloth mechanism 52, passes through the cloth spreading mechanism 53, the front spreading mechanism 54, the cloth feeding mechanism 56 to the cloth cutting device 57, and slides the manipulator clamping mechanism 4 on the bedding bed 1 with the cutting dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com