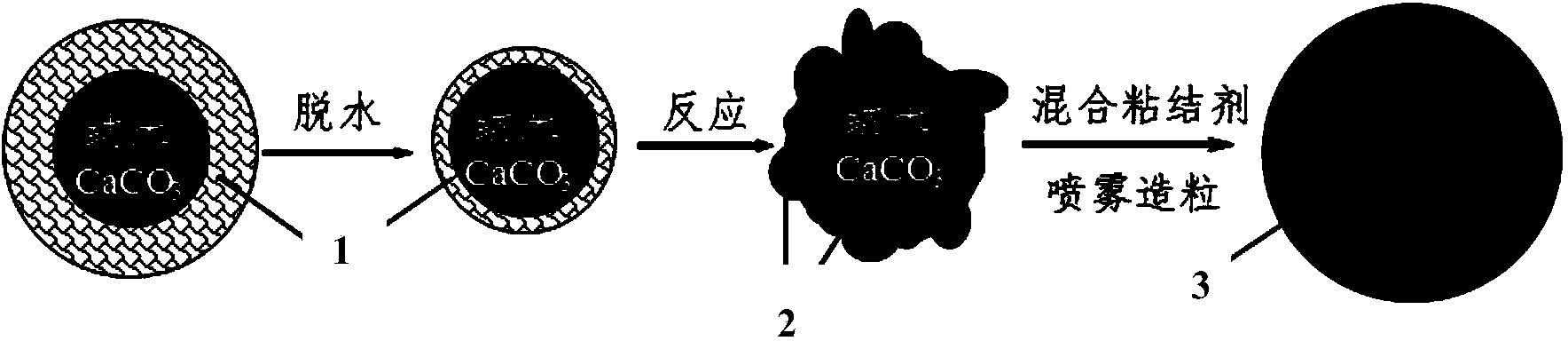

Surface coating modified nano calcium oxide based CO2 adsorbing agent and preparation method thereof

A nano-calcium oxide, surface coating technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of no reported coating, low adsorption efficiency, long synthesis time, etc., and achieve good microstructure performance. , the method is simple, the effect of modification stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

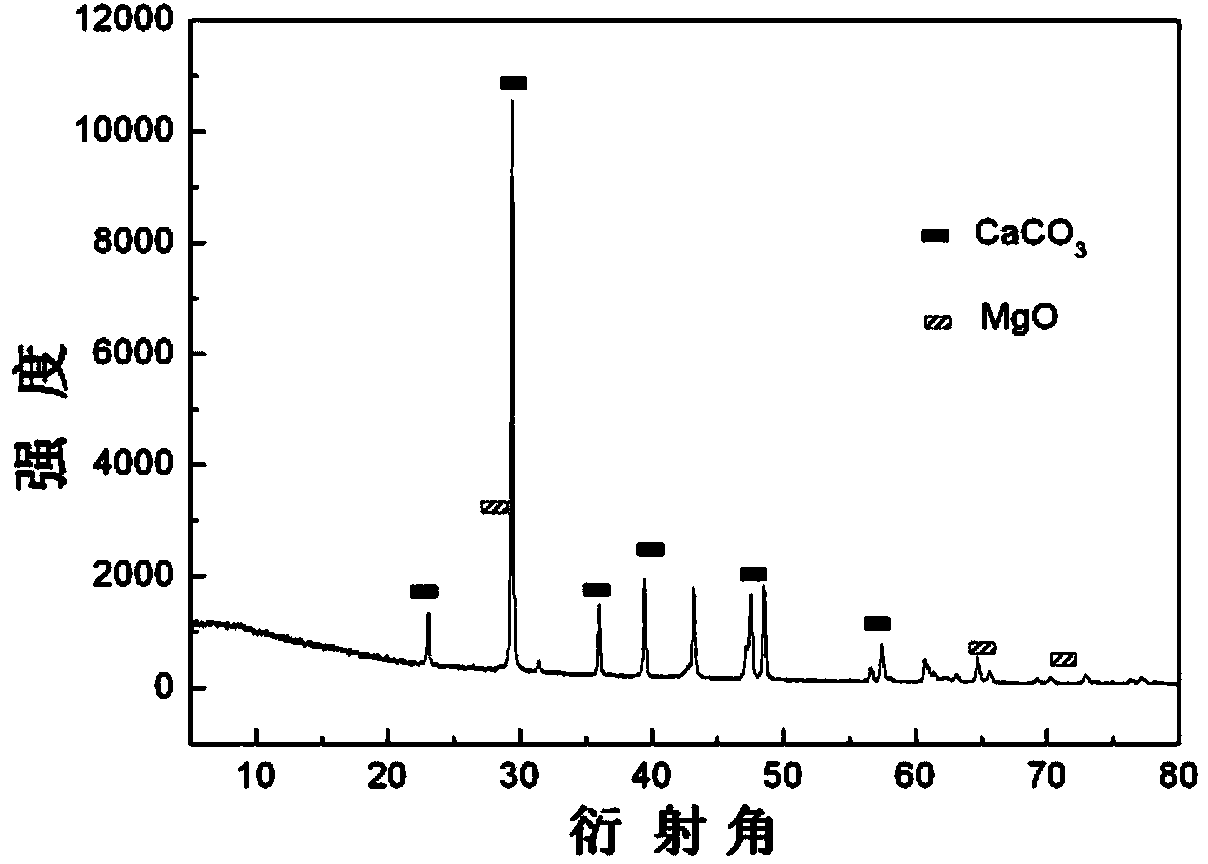

[0060] (1) Disperse 19 g of nanometer calcium carbonate dry powder and 10 g of water in absolute ethanol by an ultrasonic disperser to form a suspension.

[0061] (2) Add 57g of 3A molecular sieve to the above suspension, leave it to stand for 30 minutes to remove water, filter out the molecular sieve, and obtain a dehydrated suspension.

[0062] (3) Add 2.8g KOH to the dehydrated suspension, and stir evenly.

[0063] (4) 5.1g MgCl 2 ·6H 2 After O was dissolved in absolute ethanol, it was gradually added to the mixed solution obtained in step (3), and stirring was continued at room temperature 25°C for 2 hours.

[0064] (5) Suction filtration, after washing, disperse the filter cake in water to obtain a coated modified nano calcium carbonate slurry, the dry basis of which contains Mg(OH) 2 The content is 5%, and the content of nano calcium carbonate is 95%.

[0065] (6) According to the ratio of nano calcium carbonate 85: aluminum sol 15, add 0.5g sodium hexametaphosphate, add an approp...

Embodiment 2

[0069] (1) Disperse 53 g of nano-calcium carbonate with 70% water content in absolute ethanol with an ultrasonic disperser to form a suspension.

[0070] (2) Add 5.3 g of activated carbon to the above suspension, stand for 30 minutes to remove water, filter out the molecular sieve, and obtain a dehydrated suspension.

[0071] (3) Add 8g of NaOH to the dehydrated suspension, and keep stirring at 50°C for 2h.

[0072] (4) 25.6g Mg(NO 3 ) 2 ·6H 2 After O was dissolved in absolute ethanol, it was gradually added to the mixed solution obtained in step (3), and stirring was continued at a temperature of 50°C for 4 hours.

[0073] (5) Suction filtration, disperse the filter cake in water after washing to obtain a coated modified nano calcium carbonate slurry, the dry basis of which contains Mg(OH) 2 The content is 20% and the content of nano calcium carbonate is 80%.

[0074] (6) According to the ratio of nano calcium carbonate 75: aluminum sol 25, add 0.8 g of sodium lauryl benzoic acid, add ...

Embodiment 3

[0076] (1) Disperse 35 g of nano calcium carbonate with 50% water content in absolute ethanol with an ultrasonic disperser to form a suspension.

[0077] (2) Add 18g of 3A molecular sieve to the above suspension, leave it to stand for 30 minutes to remove water, filter out the molecular sieve, and obtain a dehydrated suspension.

[0078] (3) Add 4.8 g of NaOH to the dehydrated suspension, and stir evenly at a temperature of 70°C.

[0079] (4) 12.2g MgCl 2 ·6H 2 After O was dissolved in absolute ethanol, it was gradually added to the mixed solution obtained in step (3), and stirring was continued at a temperature of 70°C for 4 hours.

[0080] (5) Suction filtration, disperse the filter cake in water after washing to obtain a coated modified nano calcium carbonate slurry, the dry basis of which contains Mg(OH) 2 The content is 12% and the content of nano calcium carbonate is 88%.

[0081] (6) According to the ratio of nano calcium carbonate 80: aluminum sol 20, add 0.6g stearic acid polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com