Method and apparatus for manufacturing wet wipes

a technology of wet wipes and manufacturing methods, applied in the direction of carpet cleaners, paper/cardboard containers, cleaning machines, etc., can solve the problems of variable impregnation amount of predetermined chemicals, increasing the size of the apparatus, and reducing so as to increase the impregnation rate of predetermined chemicals, prevent variability of predetermined chemical impregnation amount, and reduce the easiness of taking sheets out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

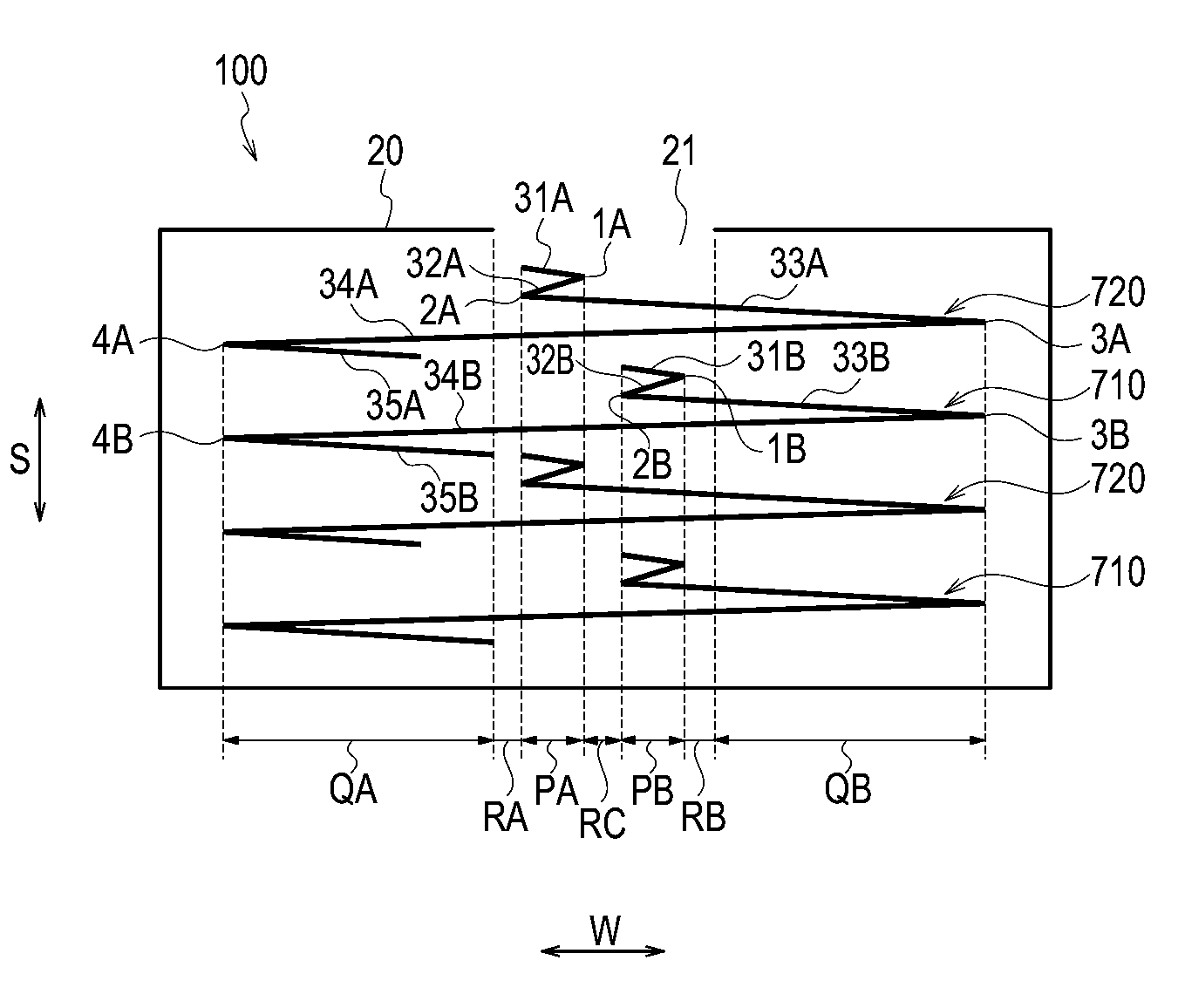

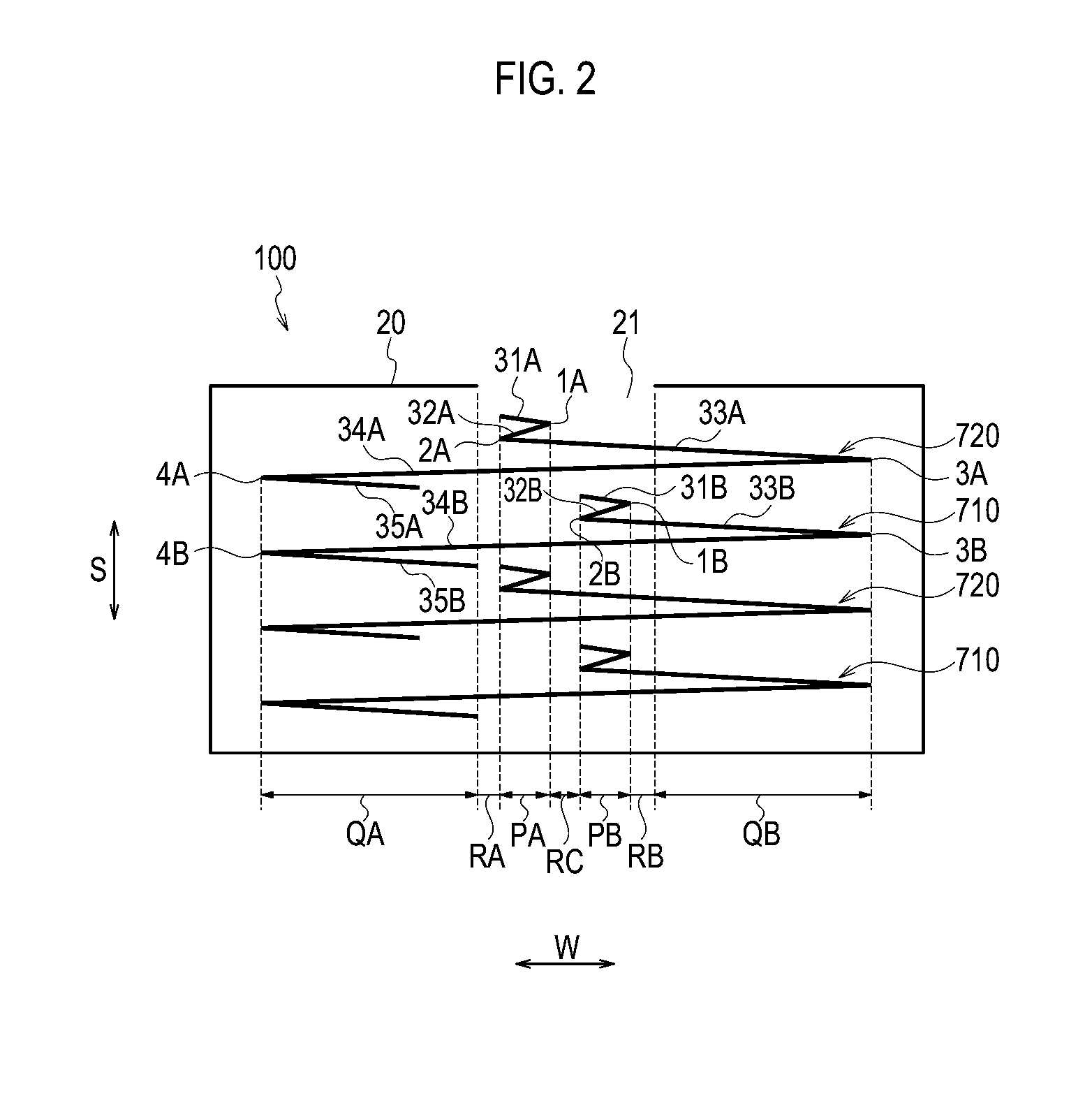

[0090]A take-out test was performed by packaging the laminated body formed of seventy-two sheets in the package main body and taking sheets out one by one. The results are shown in FIGS. 7(a) to 7(c). Specifically, a manufacturing line that one set was formed by stacking four sheets was made. That is, the laminated body formed of eighteen sets was produced and sealed in the package body.

[0091]FIG. 7(a) shows the results of a take-out test performed to the laminated body to which the pressing step was not performed. FIG. 7(b) shows the results of a take-out test performed to the laminated body in which the entire surface was pressed. FIG. 7(c) shows the results of a take-out performed to the laminated body to which the pressing step was performed by the pressing device according to the embodiment. In FIGS. 7(a) to 7(c), the vertical axis shows the amount of a pulled-out portion of subsequent sheet in the event of pop-up (a phenomenon that a subsequent sheet is pulled out in associati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical | aaaaa | aaaaa |

| conveyance speed | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com