Copper-impregnated carbon contact strip material and preparation method of copper-impregnated contact strip

A carbon sliding plate, copper immersion technology, applied in electric vehicles, power collectors, transportation and packaging, etc., can solve the problems of complex preparation process, low metal impregnation efficiency, etc., and achieve high impregnation rate, high mechanical and wear resistance. , the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

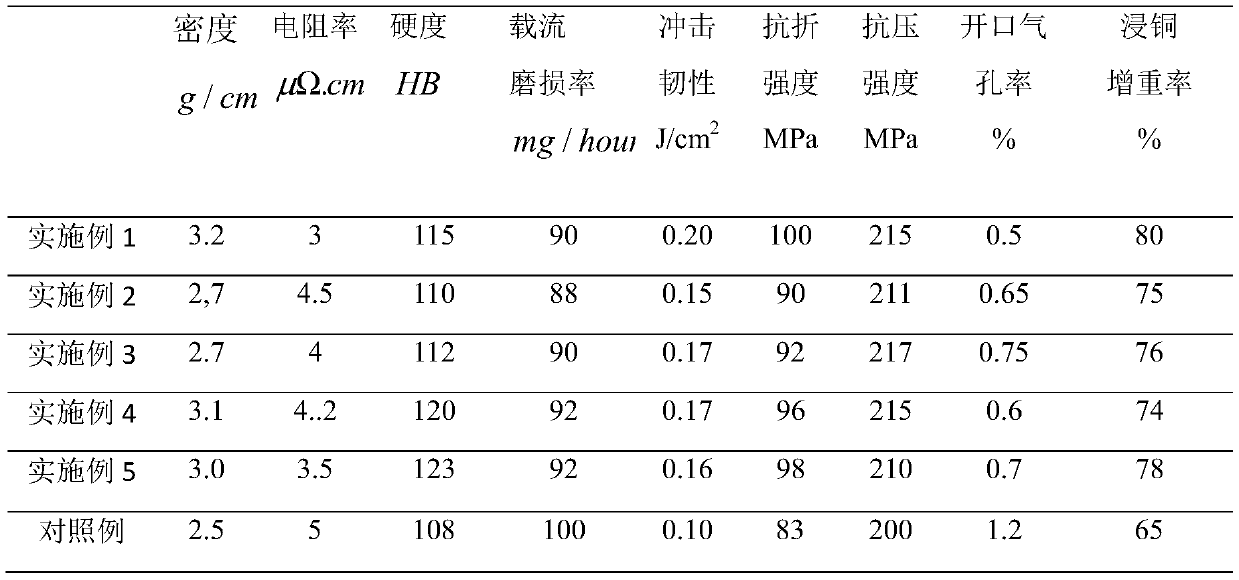

Examples

preparation example Construction

[0029] The preparation method of copper-impregnated carbon sliding plate of the present invention, its step comprises:

[0030] (1) After stirring the carbon slide material at a temperature of 120°C to 150°C for 40min to 60min, kneading at a temperature of 150°C to 200°C for 80min to 100min;

[0031] Use metal wires to build a three-dimensional network structure in advance, first place it in the pressing mold, then pour the kneaded carbon skateboard material into the pressing mold, and pre-press the pressing mold for 30 minutes at a pressure of 15MPa-25MPa -50min, solidify the pressed material column at a temperature of 120℃~180℃ for 4h~8h, press the solidified material column into a carbon skateboard blank; Calcined at 1200°C for 1h-2h to make a carbon slide.

[0032] Wherein, the metal wire used is metal or metal oxide that can react with acid, and the diameter of the metal wire is less than 10 μm.

[0033] (2) Immerse the carbon slide with the metal wire inside to form a ...

Embodiment 1

[0036] The carbon slide material in this embodiment includes 30 parts of petroleum coke powder, 26 parts of pitch coke powder, 5 parts of natural graphite powder and 6 parts of artificial graphite powder.

[0037] The preparation method of the copper-impregnated carbon sliding plate of the present embodiment, its step comprises:

[0038] (1) After stirring the carbon slide material at a temperature of 120°C for 40 minutes, kneading at a temperature of 150°C for 80 minutes.

[0039] Build a three-dimensional network structure with metal wires in advance, first place it in the pressing mold and then pour the kneaded carbon skateboard material into the pressing mold, first pre-press the pressing mold at a pressure of 15MPa for 30 minutes, After the pressed material column was cured at a temperature of 120° C. for 4 hours, the cured material column was pressed into a carbon skateboard blank. After the carbon slide blank is cooled, it is baked at a temperature of 800°C for 1 hour ...

Embodiment 2

[0042] The carbon slide material in this embodiment includes 35 parts of petroleum coke powder, 28 parts of pitch coke powder, 6 parts of natural graphite powder and 7 parts of artificial graphite powder.

[0043] The preparation method of the copper-impregnated carbon sliding plate of the present embodiment, its step comprises:

[0044] (1) After stirring the carbon slide material at a temperature of 130°C for 45 minutes, kneading at a temperature of 170°C for 85 minutes.

[0045] A three-dimensional network structure is built in advance with metal wires, which are first placed in the pressing mold and then the kneaded carbon skateboard material is poured into the pressing mold. The pressing mold is pre-pressed for 35 minutes at a pressure of 17 MPa. After the pressed material column was cured at a temperature of 140° C. for 5 hours, the cured material column was pressed into a carbon skateboard blank. After the carbon slide blank is cooled, it is baked at a temperature of 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com