Reinforced composite membrane for fuel cell and membrane-electrode assembly for fuel cell comprising the same

A technology for enhanced composite and fuel cells, which is applied to fuel cell components, fuel cells, battery electrodes, etc., and can solve the problem of low competition between fluorine-based ion conductors and fluorine-based porous supports, and the inability of hydrocarbon-based ion conductors to use fluorine-based Porous supports etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

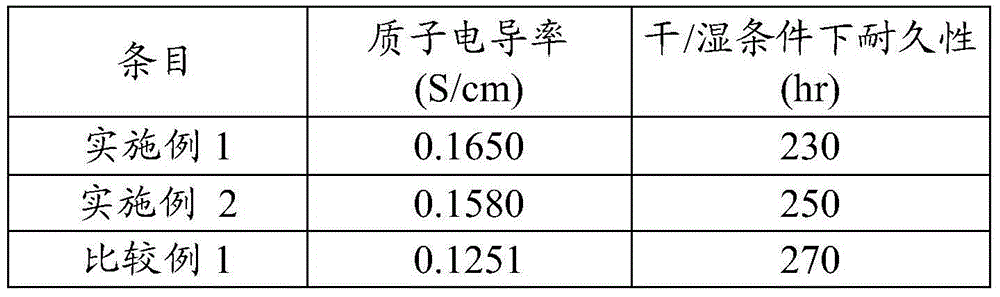

Embodiment 1

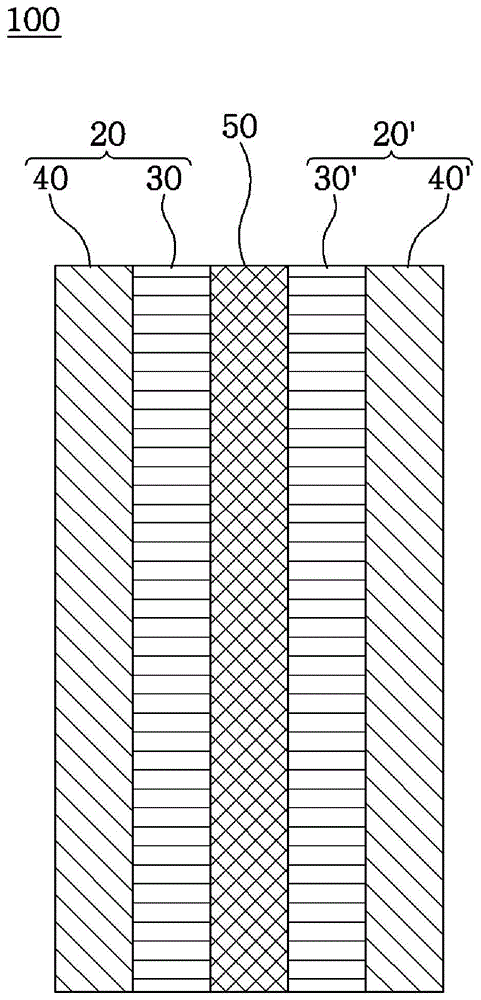

[0108] The poly(amic acid) / tetrahydrofuran spinning solution with 25% weight concentration is applied to the first spinning nozzle, and the sulfonated polysulfone / tetrahydrofuran spinning solution with 5% weight concentration is applied to the second spinning nozzle, and electrospinning Performed under an applied voltage of 30KV to produce a polyamic acid porous support. Then, the polyamic acid porous support was impregnated in a solution consisting of pyridine and triethylamine mixed at a ratio of 2:1 to induce an imidization reaction, resulting in a porous support with an average thickness of 15 μm and insoluble in organic solvents .

[0109] The resulting porous support was coated twice with a 20% ion conductor solution of sulfonated polyarylethersulfone (S-PAES) as the second ion conductor using a doctor blade. Then, the porous support was dried at 80 °C for 1 hour and placed in a vacuum electric furnace for 1 hour to fabricate a reinforced composite membrane.

[0110] T...

Embodiment 2

[0112] In addition to using a polyamic acid / THF spinning solution with a concentration of 25% by weight and a sulfonated polysulfone / THF spinning solution with a concentration of 5% by weight, so that the ratio of the total weight of polysulfone to polyamic acid is A membrane electrode assembly was produced in the same manner as in Example 1, except that the support body precursor was produced by spinning the resulting mixture in one nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com