A kind of drying method for preparing electrode based on blade coating method and its electrode and application

A technology for preparing electrodes and a drying method, which is applied to the drying of electrodes prepared based on the blade coating method, as well as the electrodes and application fields, can solve the problems of small particles, easy falling off of active substances, insufficient adhesion, etc. Liquid absorption rate and specific surface area, the effect of improving the rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

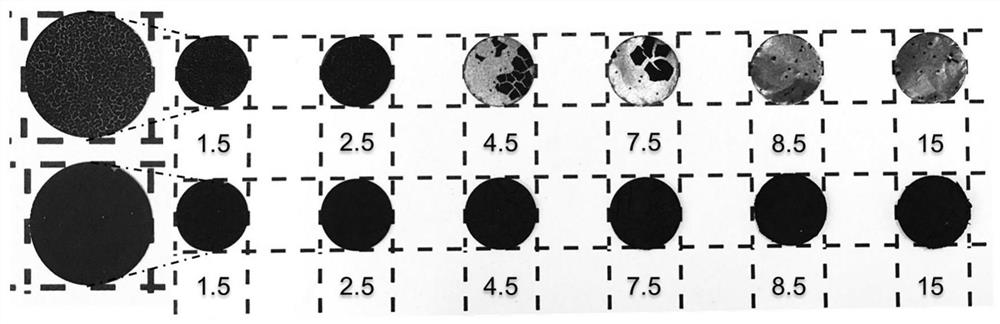

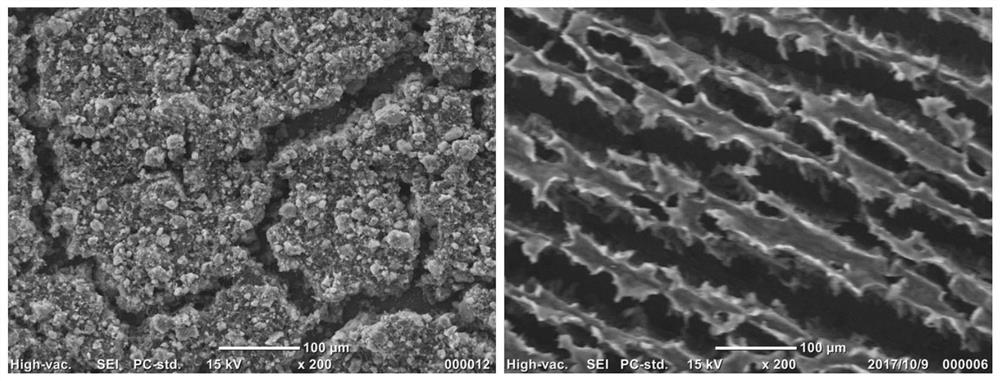

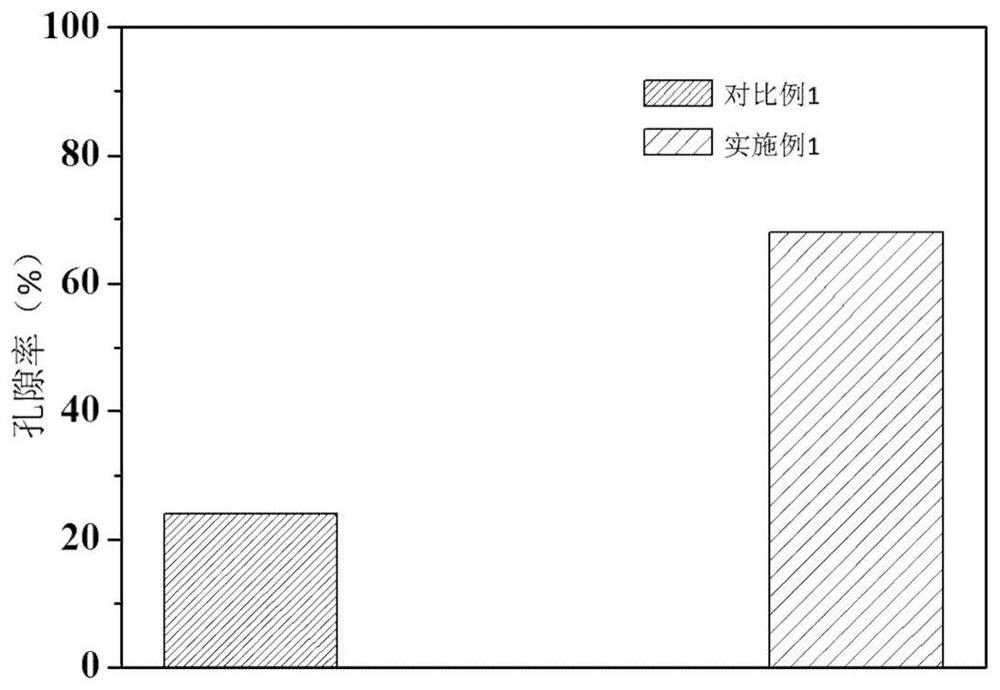

Embodiment 1

[0032] Dissolve 0.03g carboxymethylcellulose (CMC) in 4g deionized water, stir for 1h, add 0.8gS / A-KB600 and 0.1g graphene, stir for 5h, then add 0.15g 40wt% styrene-butadiene rubber (SBR), Stir at a slow speed for 0.5h, adjust the scraper to 500μm to scrape and coat on the aluminum film, quickly immerse in liquid nitrogen, take it out after 10min, and quickly transfer to a freeze dryer (temperature -50°C, vacuum <10) to dry 10h, dry overnight at 50°C. Subsequent electrode preparation and battery assembly are the same as in Comparative Example 1.

[0033] The first discharge specific capacity at 0.1C rate is 1203mA h g -1 , when the rate is increased to 2C, the discharge specific capacity is 675mA h g -1 .

Embodiment 2

[0038] Dissolve 0.03g of carboxymethyl cellulose (CMC) in 4g of deionized water, stir for 1 hour, add 0.8g of LFP and 0.1g of Super P, and then prepare the electrode and assemble the battery as in Example 1.

[0039] The first discharge specific capacity is 160.9mA h g at 0.2C rate -1 , when the rate is increased to 10C, the discharge specific capacity is 40.6mA h g -1 .

Embodiment 3

[0044]Dissolve 0.03 g of carboxymethylcellulose (CMC) in 4 g of deionized water, stir for 1 h, add 0.8 g of NTP and 0.1 g of Super P, and then prepare the electrode and assemble the battery as in Example 1.

[0045] The specific capacity of the first cycle discharge at 0.1C rate is 86.2mAh g -1 , when the rate is increased to 10C, the specific discharge capacity is 8mAh g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com