Preparation method of 3A molecular sieve

A molecular sieve, secondary exchange technology, applied in chemical instruments and methods, A-type crystalline aluminosilicate zeolite, other chemical processes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

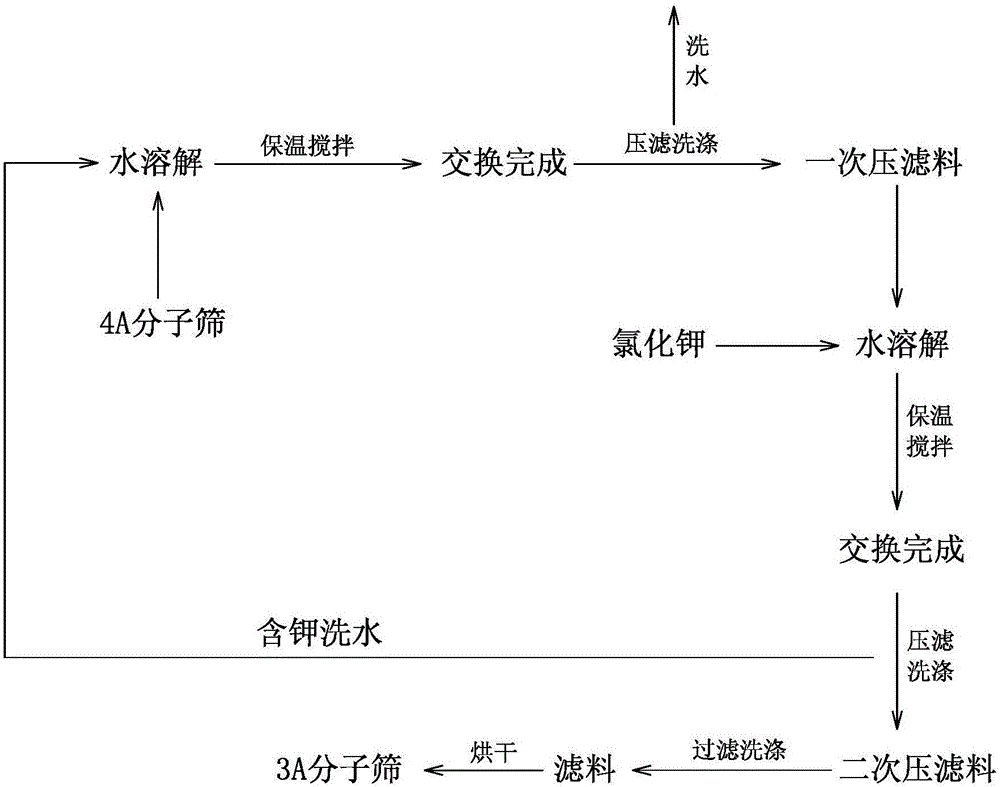

[0018] Embodiment one, with reference to figure 1 Shown, a preparation method of 3A molecular sieves, including one-time exchange and two-time exchange.

[0019] An exchange includes the following steps: 4A molecular sieve (Na 2 O·Al 2 o 3 2SiO2 2 9 / 2H2O) and the potassium-containing washing water recovered by the secondary exchange are mixed and stirred evenly in the primary exchange tank according to the solid-to-liquid mass ratio of 1:4, then the temperature is raised to 80°C, and the exchange is performed under dynamic stirring for 30 minutes. After the exchange is completed, press filter and wash Obtain the primary filter material and washing water containing sodium ions, chloride ions and a small amount of potassium ions, discharge the washing water, and send the primary filter material into the secondary exchange;

[0020] The secondary exchange includes the following steps: first put water into the secondary exchange tank, and then put in potassium chloride, put in...

Embodiment 2

[0021] Embodiment two, refer to figure 1 Shown, a preparation method of 3A molecular sieves, including one-time exchange and two-time exchange.

[0022] An exchange includes the following steps: 4A molecular sieve (Na 2 O·Al 2 o 3 2SiO2 2 9 / 2H2O) and the potassium-containing washing water recovered by the secondary exchange are mixed and stirred evenly in the primary exchange tank according to the solid-to-liquid mass ratio of 1:4, then the temperature is raised to 75°C, and the exchange is performed under dynamic stirring for 30 minutes. After the exchange is completed, press filter and wash Obtain the primary filter material and washing water containing sodium ions, chloride ions and a small amount of potassium ions, discharge the washing water, and send the primary filter material into the secondary exchange;

[0023] The secondary exchange includes the following steps: first put water into the secondary exchange tank, and then put in potassium chloride, put in a press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com