Preparation method of improved 3A molecular sieve raw powder

A molecular sieve, an improved technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as inability to meet deep drying, inability to achieve adsorption and separation performance, shorten production time, improve ion exchange rate, and reduce dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

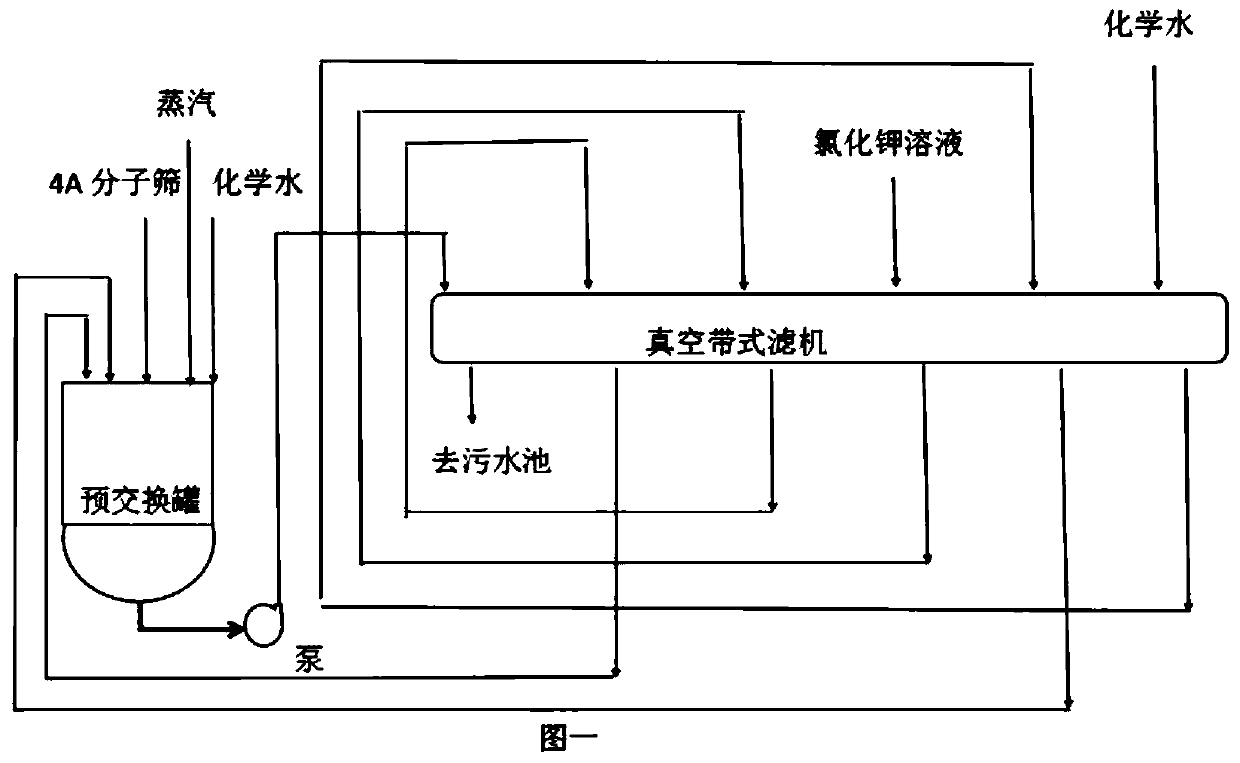

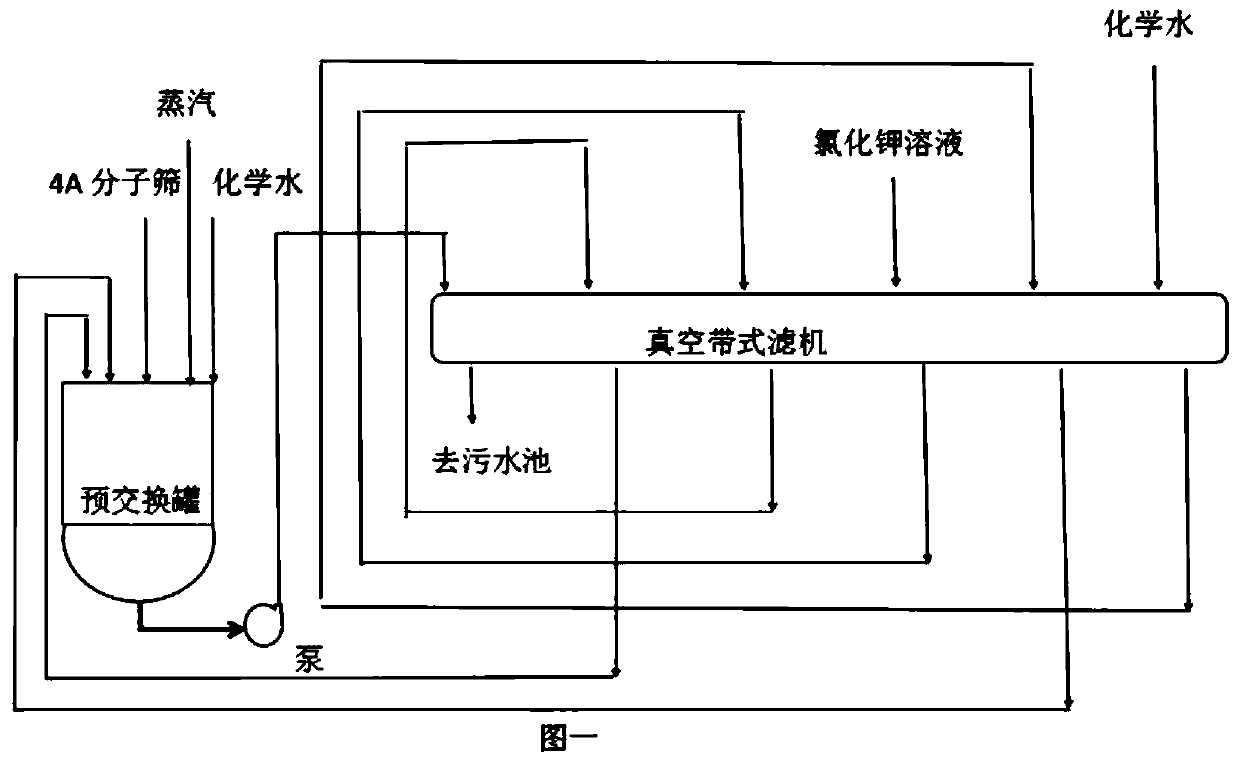

[0020] like figure 1 As shown, add 23m to the exchange tank 3 For the potassium-containing exchange solution, add 4A molecular sieve dry basis 3300Kg, heat up to 85°C with steam, add chemical water to control the solid content of the pre-exchange slurry to 125g / L. Constant temperature reaction for 3 hours. The pre-exchange slurry is sent to a vacuum belt filter, and the dry weight of molecular sieves is 500Kg / h. The mass ratio of the fourth-stage potassium-containing exchange liquid of the vacuum belt filter to the dry base of 4A molecular sieve is 0.33:1. The fourth-stage filtrate is pumped to the third stage of the filter for exchange, and the third-stage filtrate is pumped to The second level performs the exchange. Add 70°C chemical water to wash the molecular sieve in the sixth stage of the vacuum belt filter, and pump the filtrate from the sixth stage to the fifth stage to wash the molecular sieve

Embodiment 2

[0022] Add 22m to the exchange tank 3 For potassium-containing exchange solution, add 4A molecular sieve dry basis 3157Kg, heat up to 90°C with steam, add chemical water to control the solid content of the pre-exchange slurry to 120g / L. Constant temperature reaction for 3 hours. The pre-exchange slurry is sent to a vacuum belt filter, and the dry weight of molecular sieves is 590Kg / h. The mass ratio of the fourth potassium-containing exchange liquid of the vacuum belt filter to the dry base of 4A molecular sieve is 0.35:1. The fourth-stage filtrate is pumped to the third stage of the filter for exchange, and the third-stage filtrate is pumped to the first Secondary exchanges. Add chemical water at 80°C to the sixth stage of the vacuum belt filter to wash the molecular sieve, and pump the filtrate from the sixth stage to the fifth stage to wash the molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com