Autogenous curing agent for cement-based material and preparation method thereof

A technology of cement-based materials and admixtures, which is applied in the field of self-curing agents and preparations, can solve the problems of large manpower, material resources, financial resources, difficulty in guaranteeing curing effects, and no adaptation methods, so as to prevent cracking and reduce capillary walls compressive stress, shrinkage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Formula and dosage of self-curing agent:

[0025] A self-curing agent for cement-based materials, the composition of which is composed of 5% superabsorbent resin, 55% fly ash, 20% metakaolin, 10% steel slag, and 10% zeolite powder. The proportion of self-curing agent in concrete cementitious material is 2%.

[0026] A preparation method for a self-curing agent for cement-based materials, comprising the following steps:

[0027] 1) Measure the super absorbent resin and inorganic admixture according to the formula;

[0028] 2) Put the various raw materials constituting the inorganic admixture into the dryer for at least 24 hours in advance, and then naturally cool to room temperature;

[0029] 3) Add all kinds of raw materials that make up the inorganic admixture into the mixer evenly, first stir slowly for 120 seconds, then stir quickly for 60 seconds, stagnate for 60 seconds, then stir quickly for 60 seconds, then stir slowly for 120 seconds;

[0030] 4) Take out ...

Embodiment 2

[0052] 1. Formula and dosage of self-curing agent:

[0053] A self-curing agent for cement-based materials, the weight percentage of its composition is: super absorbent resin 10%, fly ash 30%, silica fume 10%, slag powder 10%, metakaolin 18%, rice husk ash 5%, steel slag 5%, bentonite 6%, zeolite powder 6%. The proportion of self-curing agent in concrete cementitious material is 1%. Its preparation method is with embodiment 1.

[0054] 2. Concrete mix ratio, see Table 6:

[0055] Table 6 Concrete mix ratio

[0056]

[0057] 3. Performance testing of concrete mixed with self-curing agent:

[0058] (1) Work performance test, the results are shown in Table 7

[0059] Table 7 Concrete slump detection

[0060]

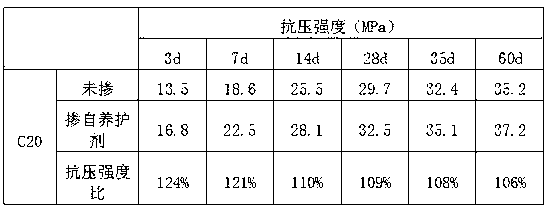

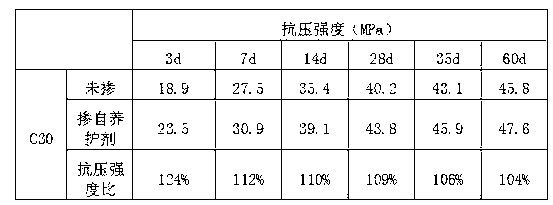

[0061] (2) Compressive strength testing, the results are shown in Table 8

[0062] Table 8 Statistical table of compressive strength testing results

[0063]

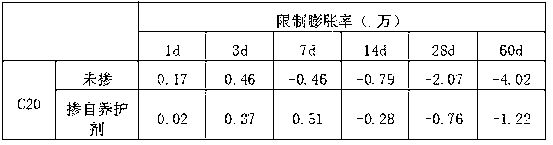

[0064] (3) Shrinkage performance test, the results are shown in Table 9

[0065] Table 9 Statistic...

Embodiment 3

[0072] Self-curing agent formula:

[0073] A self-curing agent for cement-based materials, the composition of which is composed of 50% superabsorbent resin, 25% fly ash, 10% steel slag powder, and 15% attapulgite. Its preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com