Short-brace rod type expanding-chord truss and producing method thereof

A technique for tensioning string trusses and trusses, which is applied in the field of new type tensioning string trusses with short struts and their production fields, can solve the problems of low shear stiffness, poor safety, and increased steel consumption, so as to improve the bearing capacity of the structure. , The effect of reducing the cross-sectional area and reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

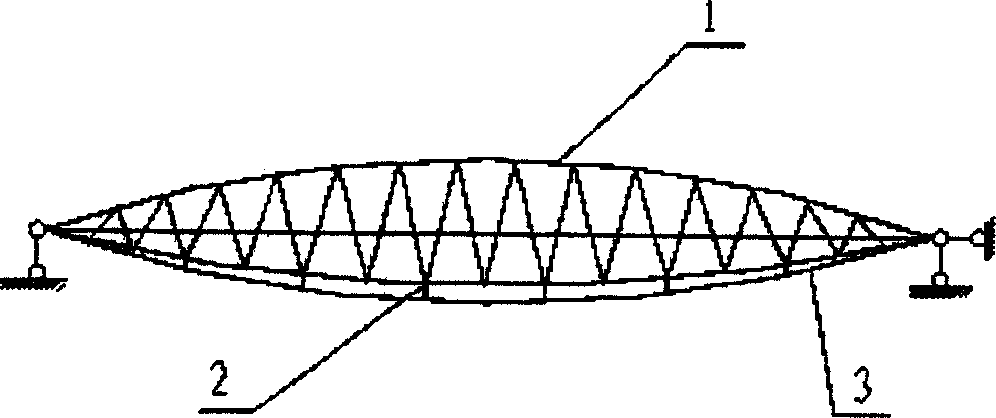

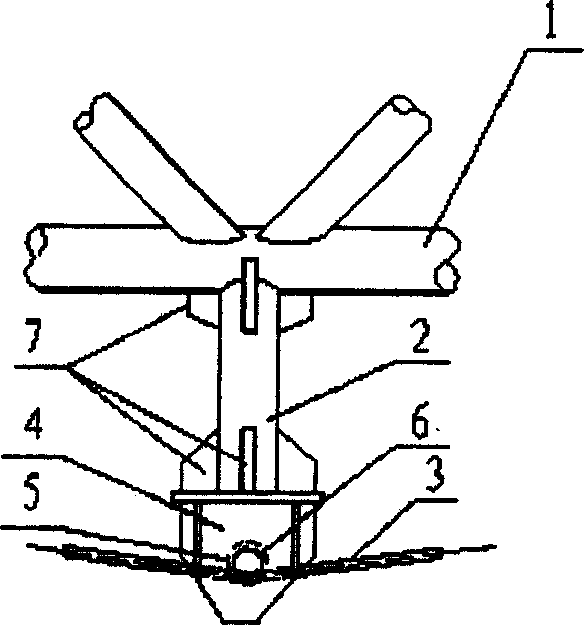

[0025] Embodiment 1 of the present invention: as figure 1As shown, it uses a shuttle-shaped truss (1) as the frame body, and welds a row of vertical short braces (2) with a length of 0.3m to 2.0m on the lower chord of the shuttle-shaped truss (1). The distance between the rods (2) is controlled within 1 to 2 pitches of the shuttle truss (1), and a shaft frame (4) is welded at the lower part of each vertical short strut (2). Stiffeners (7) are welded between the axle frame (4) and each vertical short strut (2) and between each vertical short strut (2) and the shuttle truss (1). Load onto two rolling bearings (5) on the axle frame (4), and all load onto an axle (5) on the rolling bearing (5), open arc groove in the center of axle (5), wire cable (3) respectively attached to the grooves of each shaft (5), and then use the support nodes at both ends of the shuttle truss (1) and the top nodes of each vertical short strut (2) as the supports for the steel cables (3) Tension the st...

Embodiment 2

[0026] Embodiment 2 of the present invention: as Figure 8 As shown, the upper part of the shuttle truss (1) is made into a three-dimensional shuttle truss type "beam" in the traditional way earlier, and all the other manufacturing methods are the same as in embodiment 1.

Embodiment 3

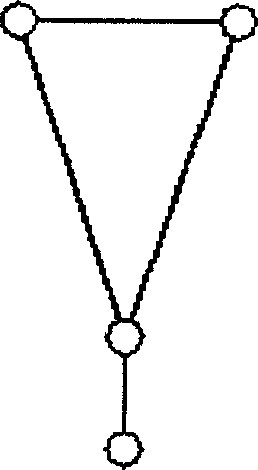

[0027] Embodiment 3 of the present invention: as Figure 10 As shown, it uses a shuttle-shaped truss (1) as the frame body, and welds a row of V-shaped diagonal short struts (2) with a length of 0.3m to 2.0m on the lower chord of the shuttle-shaped truss (1). The distance between the vertices of the bottom ends of the V-shaped short struts (2) is controlled within 1 to 2 nodes of the shuttle-shaped truss (1), and a shaft frame is welded at the bottom of each V-shaped short strut (2) (4), between each shaft frame (4) and each short V-shaped oblique brace (2) and between each V-shaped oblique short brace (2) and the shuttle-shaped truss (1) are welded Stiffener (7), load onto two rolling bearings (5) on each axle frame (4), and all load onto a shaft (5) on the rolling bearing (5), open arc in the center of shaft (5) Groove, paste the steel cables (3) on the grooves of each shaft (5) respectively, and then use the two ends of the shuttle truss (1) to support the nodes and the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com