Internal high pressure forming die and method of elbow T-branch pipe

A technology for internal high-pressure forming and tee pipes, which is applied in the field of high-pressure forming molds for tee pipes. It can solve problems such as thickening of the bottom of tee pipes, achieve uniform wall thickness, increase forming limit, and reduce compressive stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

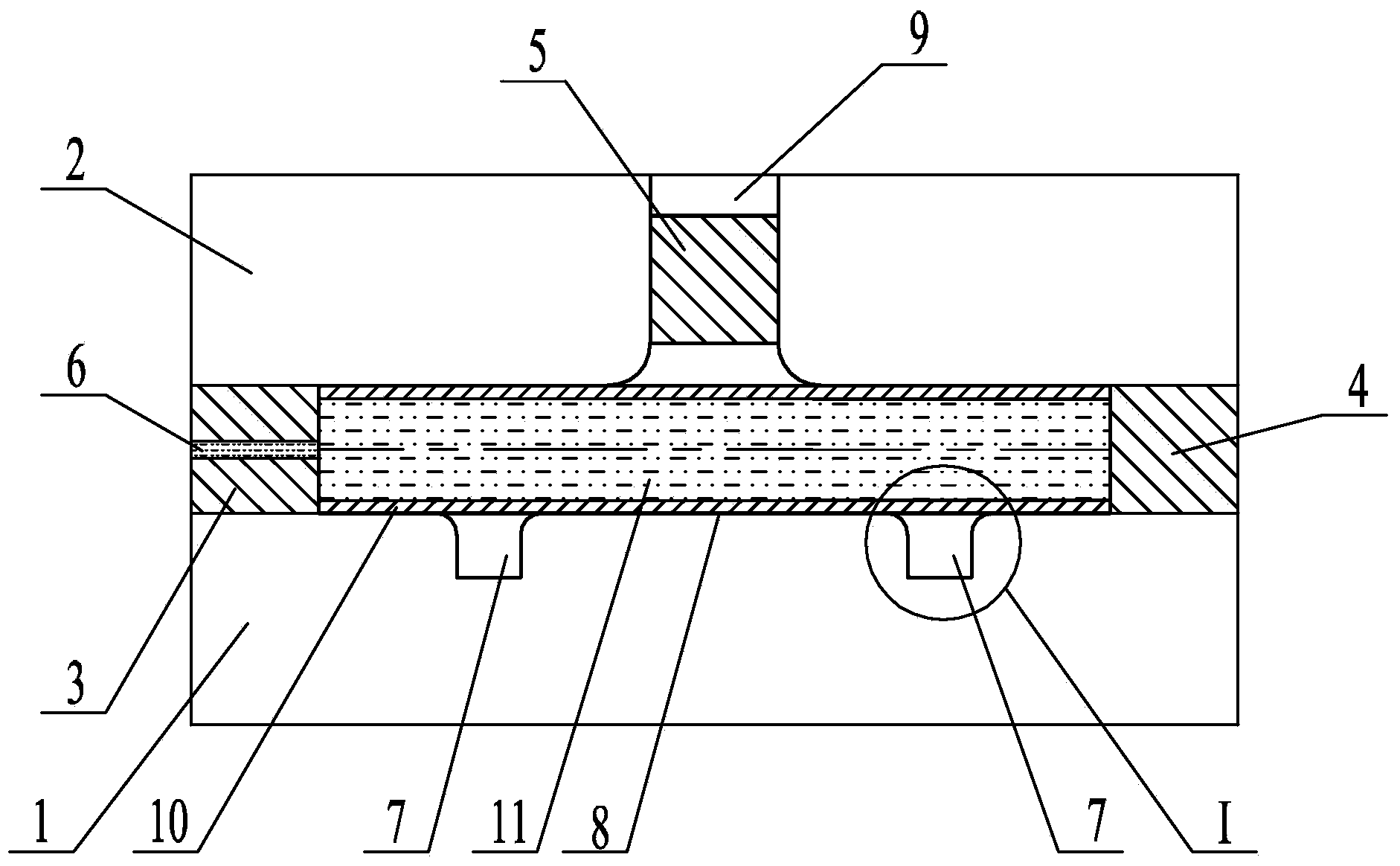

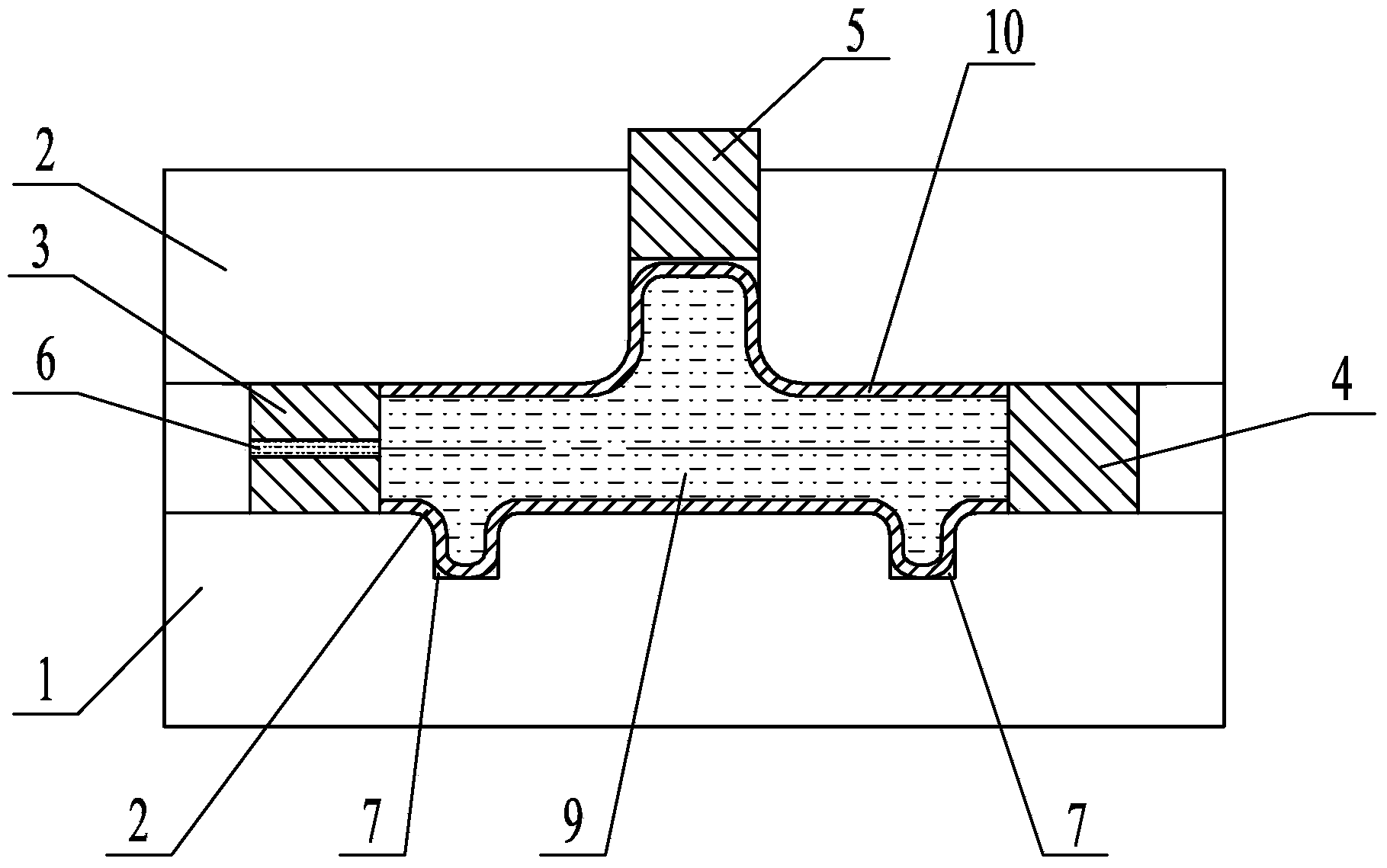

[0036] Specific implementation mode one: combine figure 1 , Figure 6 and Figure 8 Describe this embodiment, this embodiment comprises lower die 1, upper die 2, first punch 3, second punch 4 and intermediate punch 5, upper die 2 and lower die 1 are fastened and set, upper die 2 and lower die A main cavity 8 is arranged between the molds 1, the first punch 3 is set at one end of the main cavity 8, the second punch 4 is set at the other end of the main cavity 8, and the inside of the first punch 3 is provided with a Liquid hole 6, one end of the liquid injection hole 6 communicates with the main cavity 8, the other end of the liquid injection hole 6 is connected with the hydraulic system, the top of the main cavity 8 is provided with a branch cavity 9, and the main cavity 8 is connected to the branch type The cavities 9 communicate with each other, the intermediate punch 5 is arranged in the branch cavity 9, and the bottom of the main cavity 8 is provided with two storage bin...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination Figure 1 to Figure 10 Describe this implementation mode, this implementation mode is realized through the following steps:

[0038] Step 1. Determine the diameter D of the main cavity 8 according to the diameter of the tube blank 10: the diameter D of the main cavity 8 is equal to the diameter of the tube blank 10, see figure 1 and Figure 4 ;

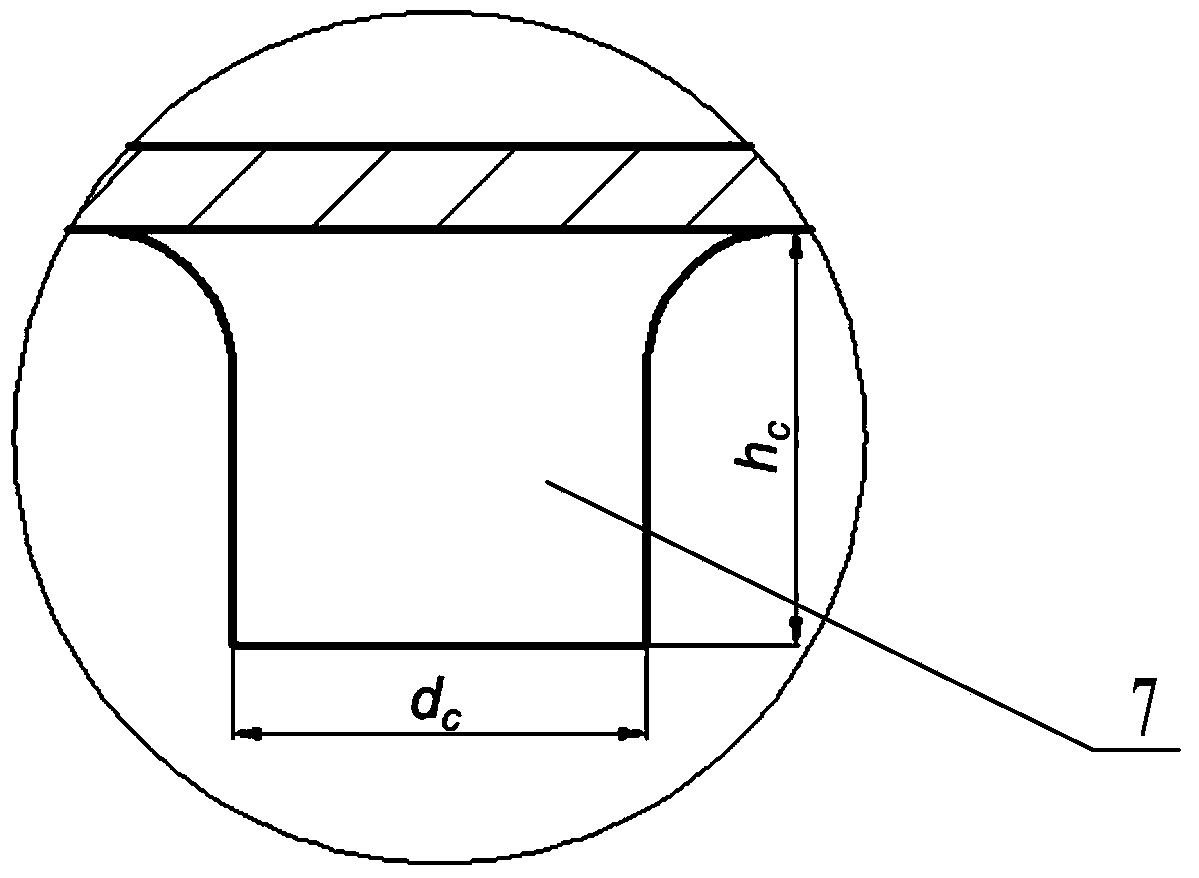

[0039] Step 2: Determine the diameter and depth of the storage bin 7 according to the diameter D of the main cavity 8: the diameter of the storage bin 7 is d c , the depth of storage bin 7 is h c ,See image 3 , the specific calculation formula is as follows:

[0040] d c ≤ ( π + α 2 π ) D or d c ≤ ...

specific Embodiment approach 3

[0049] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, in this embodiment, when the bending angle α=0° of the pipe blank 10 in step 2, the diameter d of the storage bin 7 is calculated according to formula 1 c ≤0.5D, the depth of storage bin 7 is calculated according to formula 2 as h c ≤0.5D. Other steps are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com