Structural composite wave-absorbing material and preparation method thereof

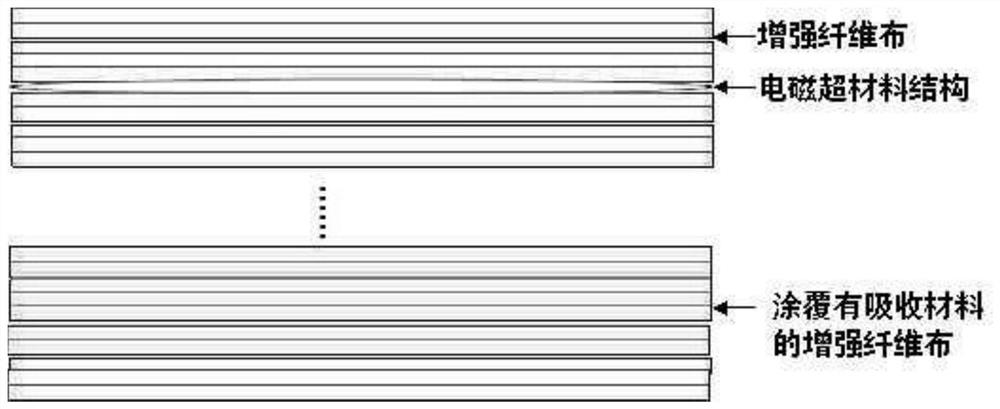

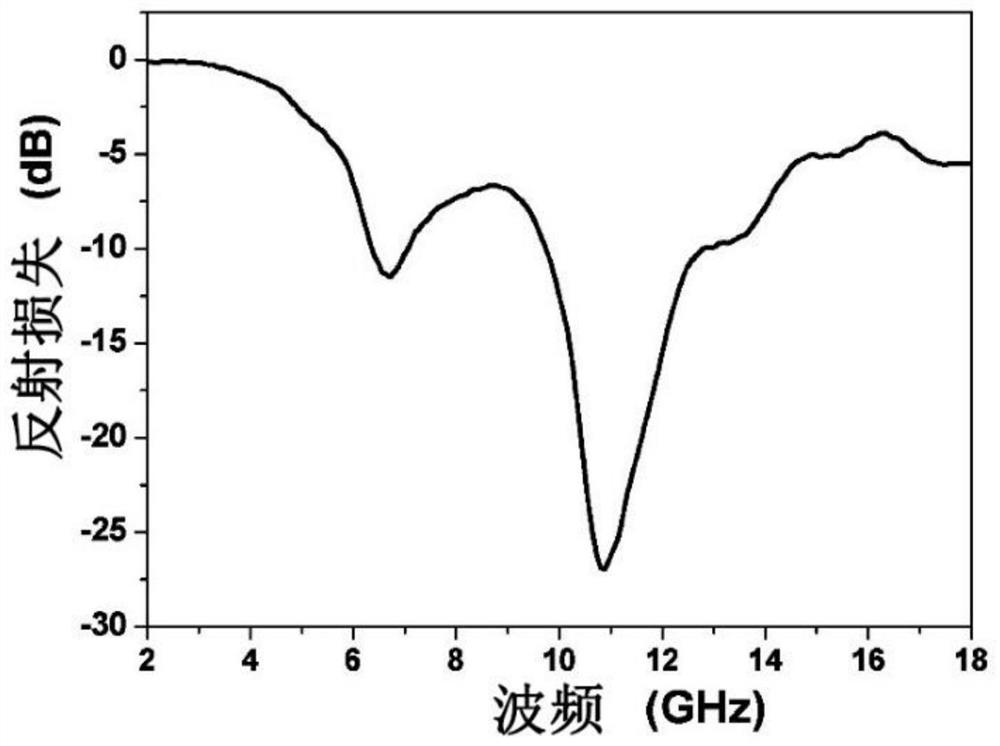

A composite wave absorbing material and composite material technology are applied in the field of structural composite wave absorbing materials and their preparation, which can solve the problems of reduced mechanical properties and increased mass, and achieve the effects of good interface compatibility, strong absorption, and widening absorption bandwidth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Select 20 layers of EW100 glass fiber cloth and 10 layers of QW100 quartz fiber cloth, and cut them into samples with a size of 180mm*180mm.

[0034] Step 2: Take 5 layers of glass fiber cloth and 10 layers of quartz fiber cloth, weigh 3068 epoxy resin according to the volume ratio of fiber and resin at 60:40, and evenly coat it on 5 layers of glass fiber cloth and 10 layers of quartz fiber On a cloth, let dry naturally.

[0035] Step 3: Take 5 layers of glass fiber cloth, weigh 3068 epoxy resin according to the volume ratio of fiber and resin at 60:40, take the magnetic metal absorbent according to the volume ratio of the magnetic metal absorbent in the resin matrix as 30%, and put It mixes well with epoxy resin. Spread it evenly on 5 layers of glass fiber cloth and let it dry naturally.

[0036] Step 4: take 10 layers of glass fiber cloth, take by weighing 3068 epoxy resin according to the volume ratio of fiber and resin as 55:45, take by weighing the magnet...

Embodiment 2

[0042] Step 1: Select 20 layers of EW100 glass fiber cloth and 10 layers of QW100 quartz fiber cloth, and cut them into samples with a size of 180mm*180mm.

[0043] Step 2: Take 5 layers of glass fiber cloth and 10 layers of quartz fiber cloth, weigh 3068 epoxy resin according to the volume ratio of fiber and resin as 55:45, and evenly coat it on 5 layers of glass fiber cloth and 10 layers of quartz fiber On a cloth, let dry naturally.

[0044] Step 3: take 5 layers of glass fiber cloth, weigh 3068 epoxy resin according to the volume ratio of fiber and resin at 50:50, take the magnetic metal absorbent according to the volume ratio of the magnetic metal absorbent in the resin matrix as 5%, and It mixes well with epoxy resin. Spread it evenly on 5 layers of glass fiber cloth and let it dry naturally.

[0045] Step 4: take 5 layers of glass fiber cloth, take by weighing 3068 epoxy resin according to the volume ratio of fiber and resin as 60:40, take by weighing the magnetic met...

Embodiment 3

[0052] The preparation steps and conditions of this embodiment are basically the same as those of Example 2, except that the volume ratio of fiber and resin in step 1 is changed to 50:50, and the magnetic absorbent is replaced by a dielectric absorbent, wherein the dielectric used in step 3 The electroabsorbent mass ratio is 0.1%, the dielectric absorbent mass ratio used in step 4 is 2%, and the dielectric absorbent mass ratio used in step 5 is 5%, then the paving in step 7 The absorber in the layer should be modified to the above ratio, and solidified to obtain a structural composite wave-absorbing material. The structural composite absorbing material also has good absorbing performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com