A metal/dielectric ultra-broadband absorption film and its preparation method

An absorption film and ultra-broadband technology, which is applied in the field of metal/dielectric ultra-broadband absorption film and its preparation, can solve the problems of not reaching the absorption threshold, limiting the application range, and narrow absorption bandwidth, so as to increase adhesion and firmness, broaden the Application range and the effect of widening the absorption bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

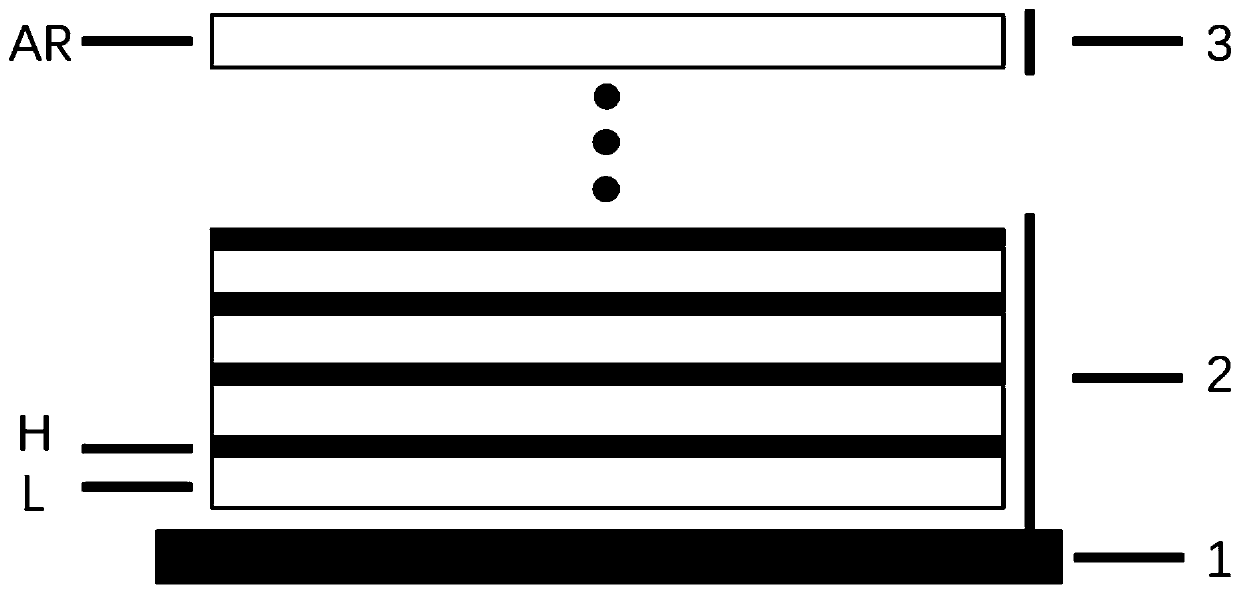

[0039] The preparation method of the above-mentioned metal / dielectric ultra-broadband absorption film includes: the determination of the number of layers of the metal / dielectric film stack; the selection of the material and film thickness of the low refractive index medium film layer L; the high absorption metal thin layer The selection of the metal material and film thickness of H; the selection of the material and film thickness of the single-layer low refractive index medium anti-reflection film AR.

[0040] The metal / dielectric ultra-broadband absorption film designed by the invention can realize wider absorption bandwidth, more stable film structure and wider application range.

Embodiment 1

[0042]In the metal / dielectric ultra-broadband absorption film provided in this embodiment, the first film structure is (LH) n1 . Since the approximate absorptivity of the film is A=1-R-T, in order to fully absorb the film system and at the same time suppress the incident light from passing through the film system to the greatest extent, the transmittance of the film system must be T=0, and n1 needs to be greater than 30, which is taken in this embodiment n1=30. At this time, the structure of the entire metal / dielectric ultra-broadband absorbing film is defined as: JGS1|(LH) 30 |Air.

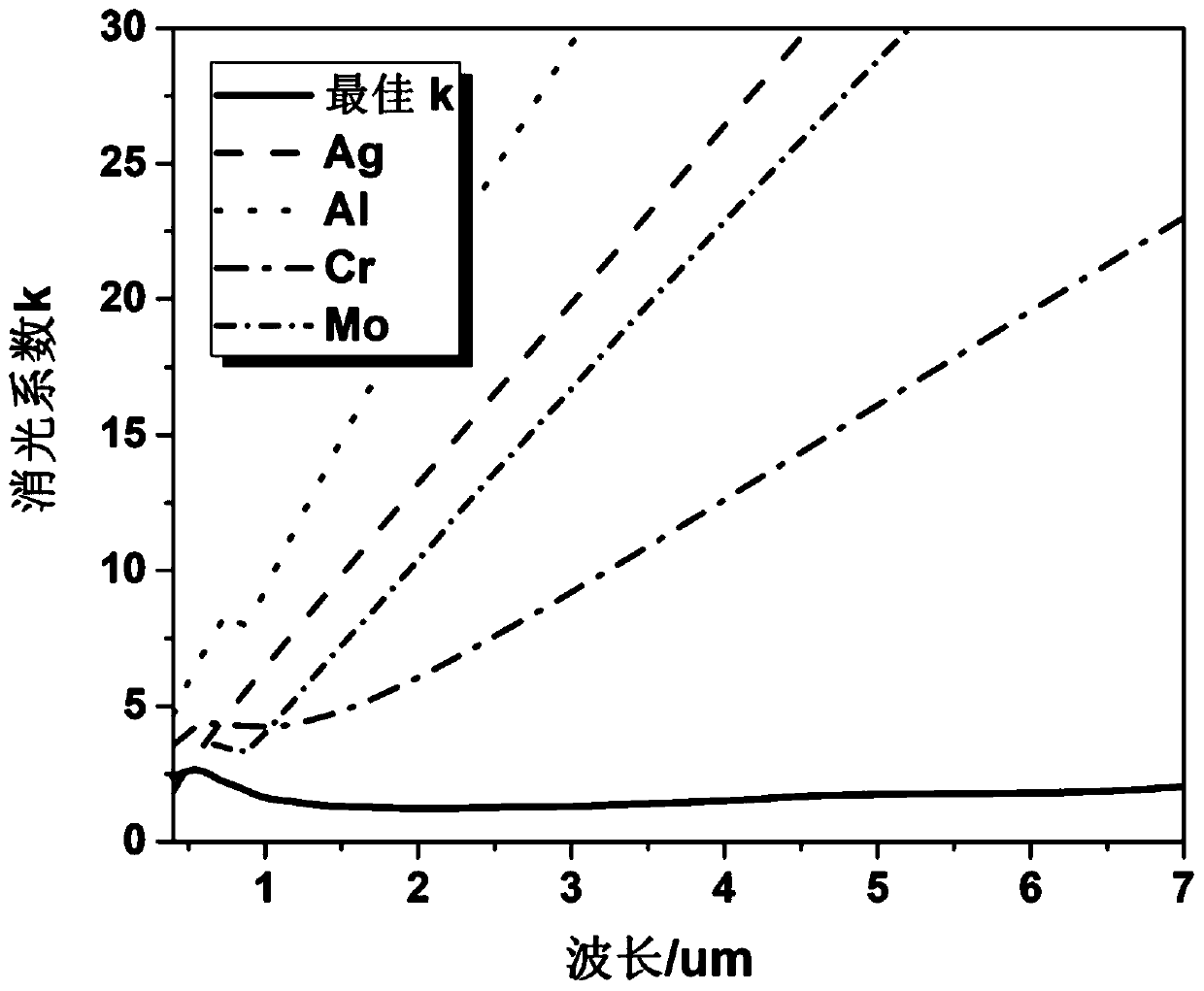

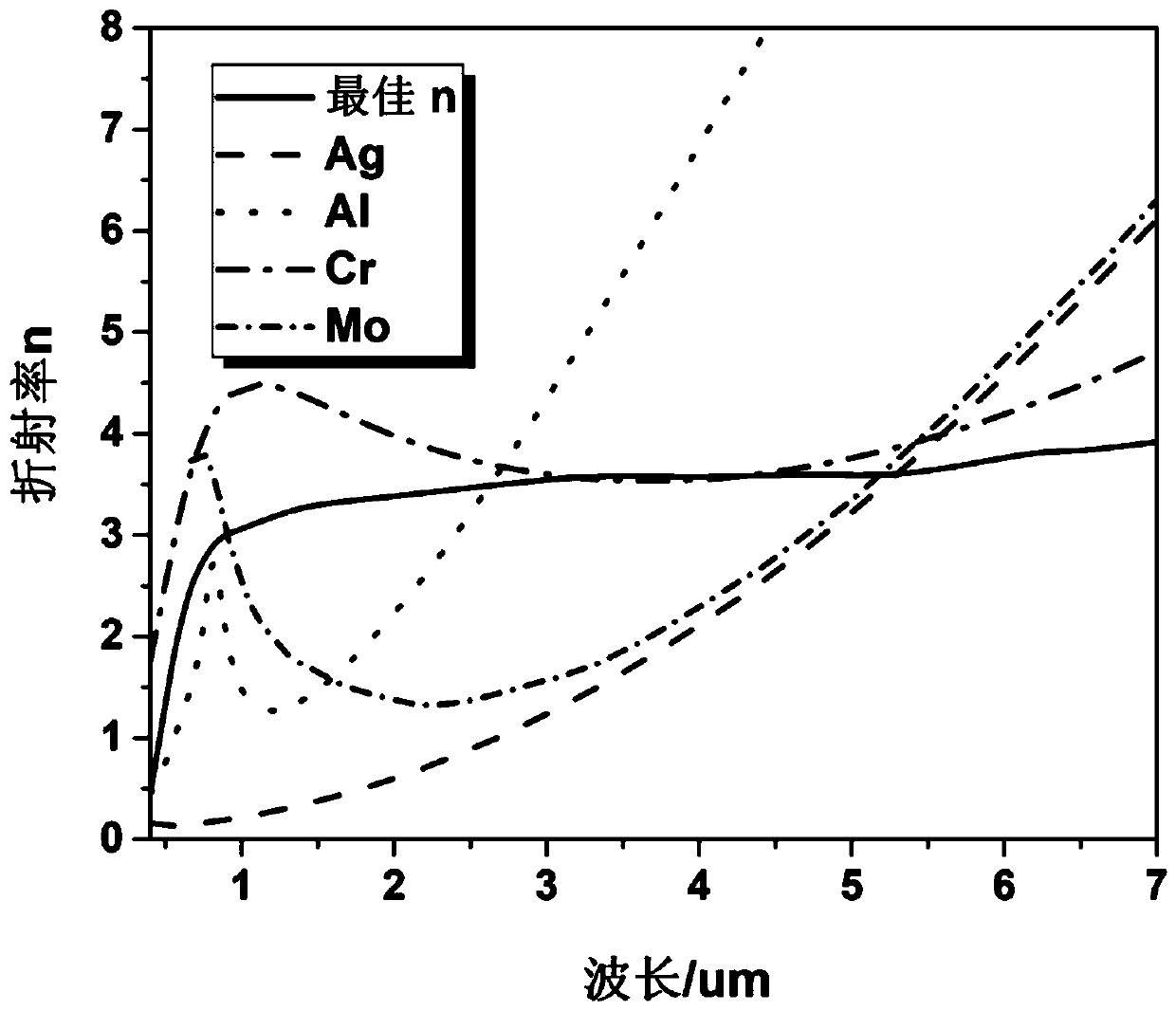

[0043] In order to make the preparation of the metal / dielectric ultra-broadband absorption film more precise, the low-refractive index dielectric film layer L can choose SiO with a relatively mature preparation process. 2 . At the same time, in this metal / dielectric structured film system, the position of the first-order Bragg reflection peak is determined by the thickness of the medium d=λ / 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com