Beryllium oxide/silicon carbide composite microwave attenuating ceramic and preparation method thereof

A technology of microwave attenuation and composite ceramics, which is applied in the field of electronic functional ceramic materials, can solve the problems of sudden change in performance of metallized attenuation ceramics, low mechanical strength of materials, and decline in dielectric properties, so as to reduce energy consumption, adjust electromagnetic parameters, absorb The effect of bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

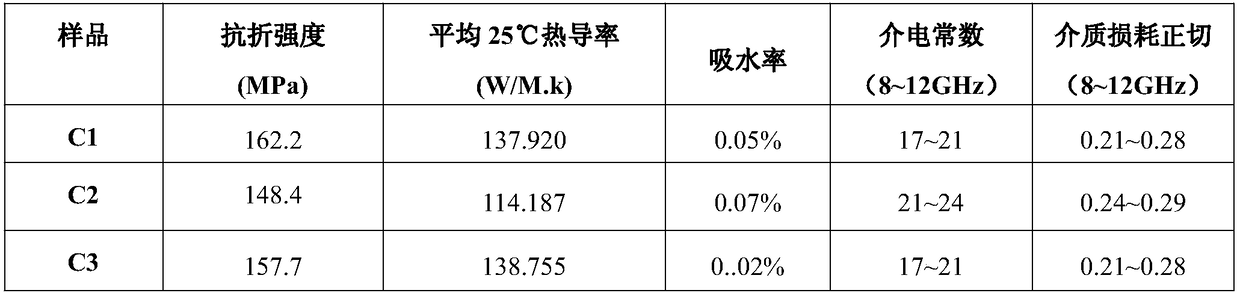

Examples

preparation example Construction

[0026] The invention provides a method for preparing beryllium oxide / silicon carbide composite microwave attenuating ceramics, the method comprising the following steps:

[0027] (1) Preparation of beryllium oxide porcelain powder:

[0028] ①. Beryllium oxide powder according to the weight ratio: magnesium trisilicate = 100: 0.5 ~ 0.55 to obtain the raw material powder, and then according to the raw material powder: deionized water: φ4 ~ 6mm zirconia ball = 1: 0.3 ~ 1: 4 ~10 Mix the three to obtain slurry, and ball mill to slurry particle size D 50 Between 0.7~1.0μm;

[0029] ②. Pass the above slurry through a 180-250 mesh screen and remove iron, dry at 150-250°C, and pass through a 180-250 mesh screen to obtain beryllium oxide porcelain powder;

[0030] (2) Preparation of composite ceramic powder:

[0031] ① Beryllium oxide porcelain powder according to mass percentage: silicon carbide powder: yttrium oxide powder = 60~80%: 18~35%: 2~5%, mix the three to obtain the total powder;

[003...

Embodiment 1

[0049] Weigh 5kg of beryllium oxide powder, 0.025kg of magnesium trisilicate, 5kg of deionized water, 22kg of zirconia balls of φ4~6mm according to the ratio. Pour the deionized water into the mixing tank of the UP mixer, and then put the zirconia balls Put into the mixing tank, turn on the ball mill mixer at 50 rpm, add beryllium oxide powder and magnesium trisilicate, and adjust the mixer speed to 130 rpm. The particle size of the slurry measured by ball milling for 30 minutes was 0.89 μm. The ball-milled slurry is passed through a 200-mesh screen, and after iron is removed, it is placed in an oven at 200°C for drying, and then passed through a 200-mesh screen to form beryllium oxide porcelain powder.

[0050] Take 400g of α-silicon carbide, 40g of yttrium oxide, 1560g of the prepared beryllium oxide porcelain powder, put it into the UP stirring ball mill, put 6kg of φ4~6mm beryllium oxide porcelain ball, add 2kg of deionized water, stir for 30min, pour Put it into a container...

Embodiment 2

[0052] Take 600g of α-silicon carbide, 40g of yttrium oxide, and 1360g of the prepared beryllium oxide porcelain powder, put them in the UP stirring ball mill, put 6kg of φ4~6mm beryllium oxide porcelain balls, add 2kg of deionized water, stir for 30min, pour After being dried in a container oven at 200°C, it is passed through a 200-mesh screen to form composite ceramic powder, and then 100g of melted paraffin is added to the composite ceramic powder, and the preparation is made by manual stirring. Dry-press forming by hydraulic press, forming pressure 150MPa, holding time 3s, wrapped in plastic bag and isostatic pressing forming, forming pressure 180MPa, holding time 45s, after forming into a 65mm×65mm×7mm green block, use Anhydrous ethanol adjusts the boron nitride powder into a paste with a mass fraction of 90%, and coats it on the surface of the green block. The upper and lower surfaces add graphite paper gaskets with a thickness of 0.1mm, and then add graphite block gaskets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com