Micro-perforated plate cobweb honeycomb sandwich sound absorption bearing composite structure

A technology of micro-perforated plate and composite structure, which is applied in the direction of sound-generating devices and instruments, can solve the problems of limited rigidity and strength, and can not be used as load-bearing parts, etc., and achieve the effect of excellent mechanical load-bearing performance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and specific embodiments.

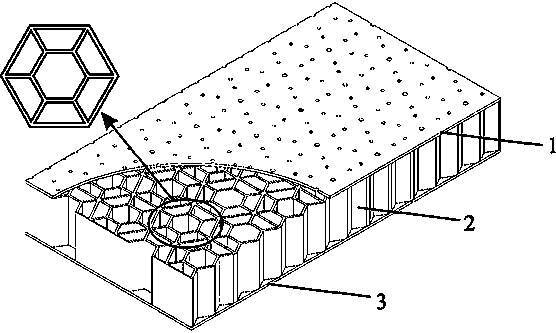

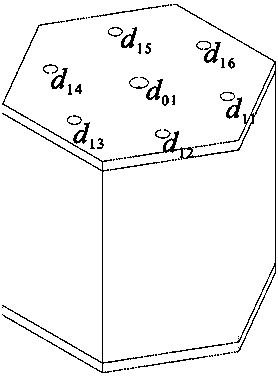

[0019] The micro-perforated plate spider web honeycomb sandwich core sound-absorbing and bearing composite structure of the present invention, such as figure 1 As shown, the upper panel 1, the spider web honeycomb core body 2 and the lower panel 3 are included. The components are welded or bonded to form an integral structure. The upper panel 1 is provided with micro-perforations, and the opening direction is perpendicular to the surface of the board. The micro-perforation and the cavity inside the spider web honeycomb form a Helmholtz resonator to absorb noise.

[0020] The micro-perforated plate spider web honeycomb sandwich core sound-absorbing and bearing composite structure can be made of wooden plates, metals, plastics, porous fibers or porous foams. The cobweb honeycomb can be filled with porous sound-absorbing materials. The purpose of this design is to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com