Heat conduction and load bearing integrated light sandwiched panel with lattice structure and preparation method thereof

A lattice structure, sandwich panel technology, applied in chemical instruments and methods, lamination devices, lamination and other directions, can solve the problems of poor thermal conductivity, single structural performance, etc., to improve thermal conductivity, reduce contact thermal resistance, high Effect of Shear Specific Strength and Specific Stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

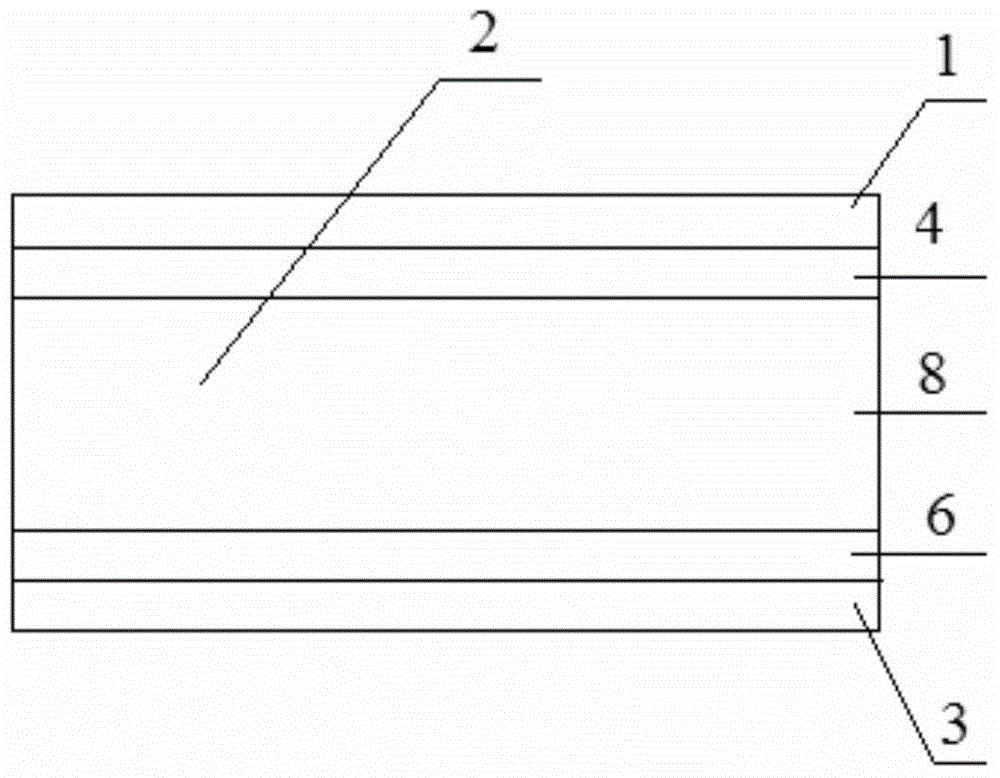

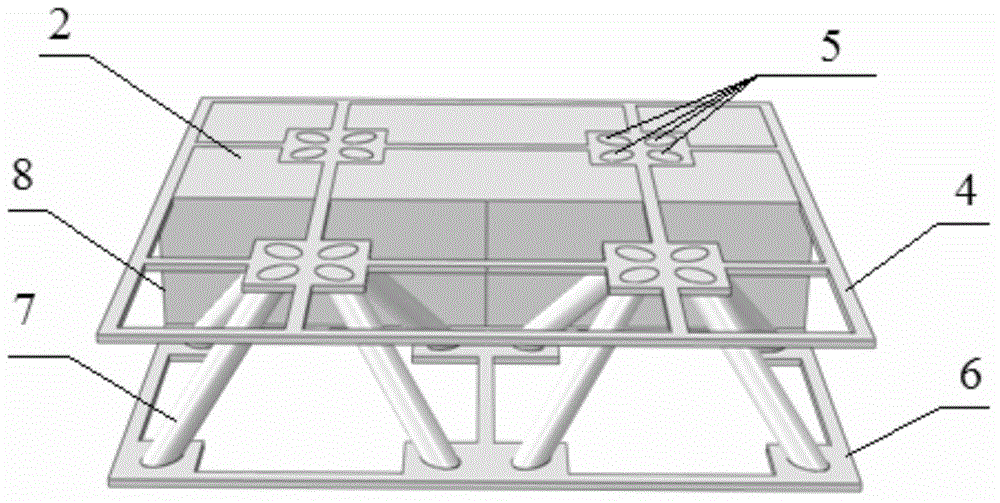

[0031] Embodiment 1: A light-weight lattice structure sandwich panel integrating heat conduction and load bearing in this embodiment is composed of an upper panel 1, a lattice structure sandwich layer 2 and a lower panel 3;

[0032] The lattice structure sandwich layer 2 is composed of an upper reinforcement net 4, a plurality of pyramidal lattice structure unit cells 5, a lower reinforcement net 6 and a carbon foam sandwich panel 8;

[0033] The unit cell 5 of the pyramid lattice structure is formed by four independent round rods 7 arranged in a pyramid shape;

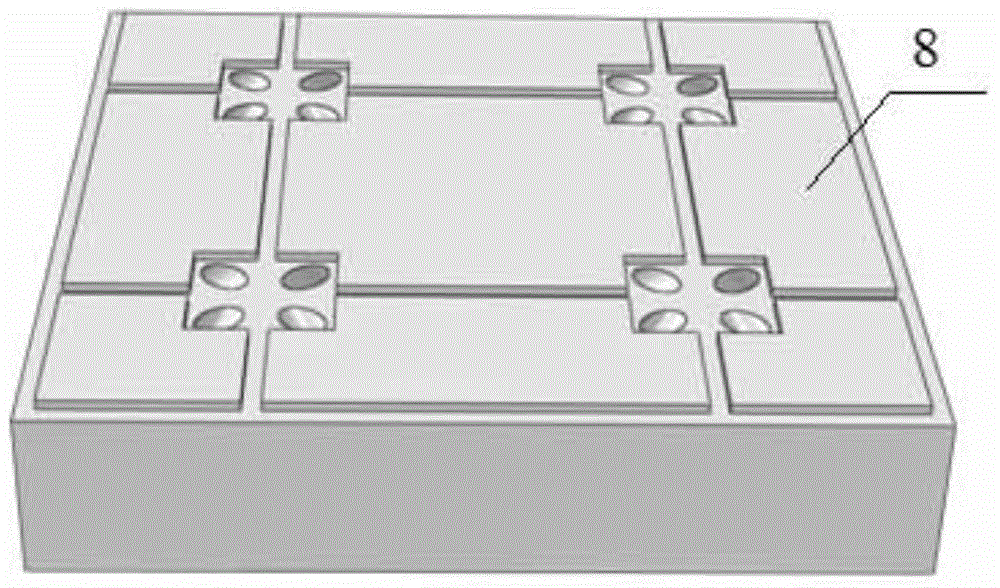

[0034] The upper reinforcing net 4 and the lower reinforcing net 6 are metal mesh panels with elliptical notches and hollowed out, each group of four elliptical notches is a group, and each group of elliptical notches is distributed in a grid. Each group of elliptical notches is set at the intersection of the structure, and the elliptical notches are through holes, and the inside of the grid of the grid structure is s...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the upper panel 1 is a carbon fiber reinforced polymer matrix composite material plate or a thin metal plate. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the lower panel 3 is a carbon fiber reinforced polymer matrix composite material plate or a thin metal plate. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com