Quantizing method for detecting corrosion defect by magnetic leakage

A technology of magnetic flux leakage detection and quantification method, which is applied in the direction of measuring device, material magnetic variable, and electromagnetic means, etc. It can solve the problems of difficult quantification of corrosion defect depth, quantification difficulty, and difficult quantification. The method is simple and easy to implement, Broad application prospects and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention can be further understood through specific examples below.

[0019] Use a pipeline magnetic flux leakage detector MT1 with 300 detection probes evenly distributed along the circumferential direction to detect the pipeline to be tested with a diameter of 273mm and a wall thickness of 10mm. The sampling interval to each probe is 2.86mm, and the distance between the detection probe and the surface of the tested sample is 3mm.

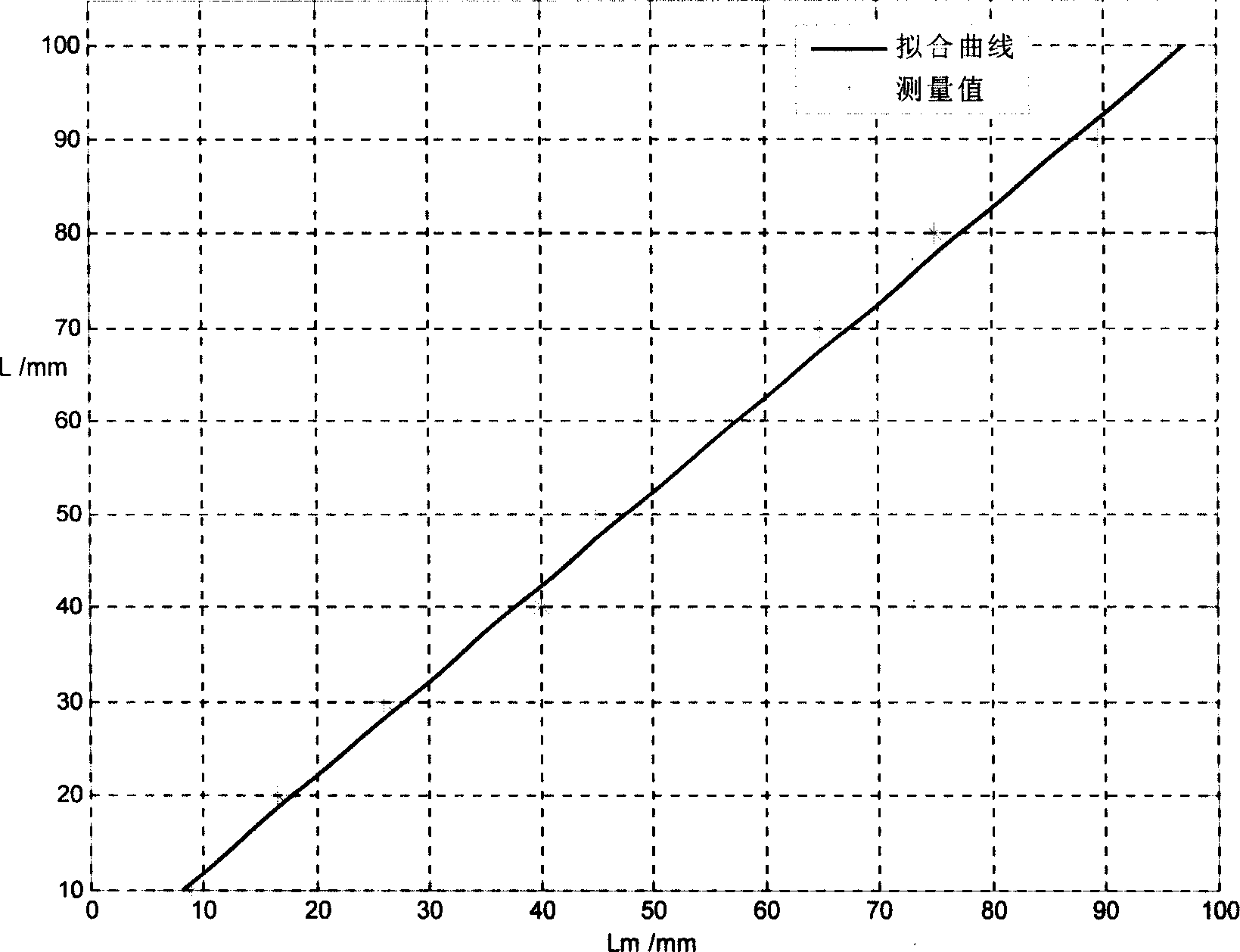

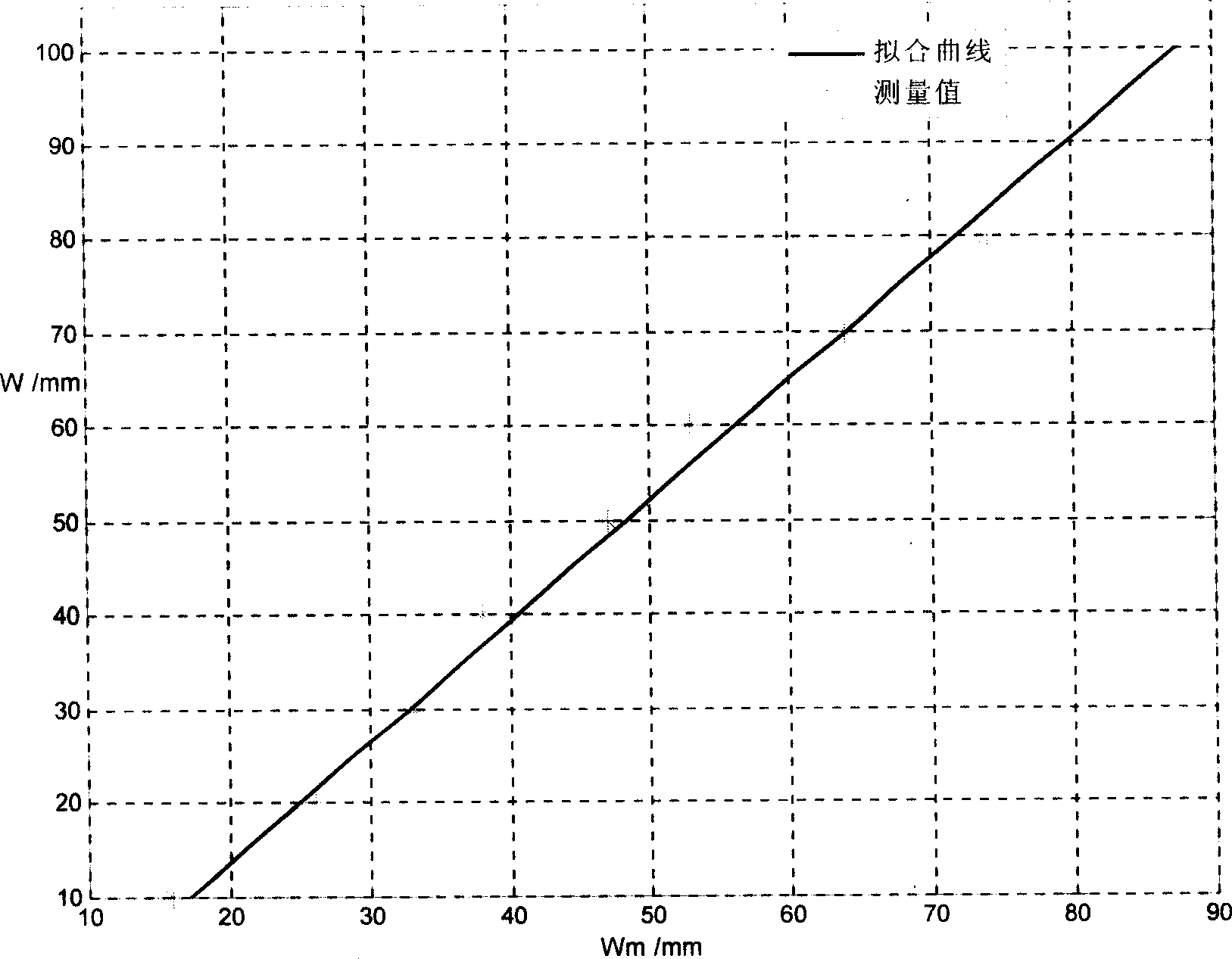

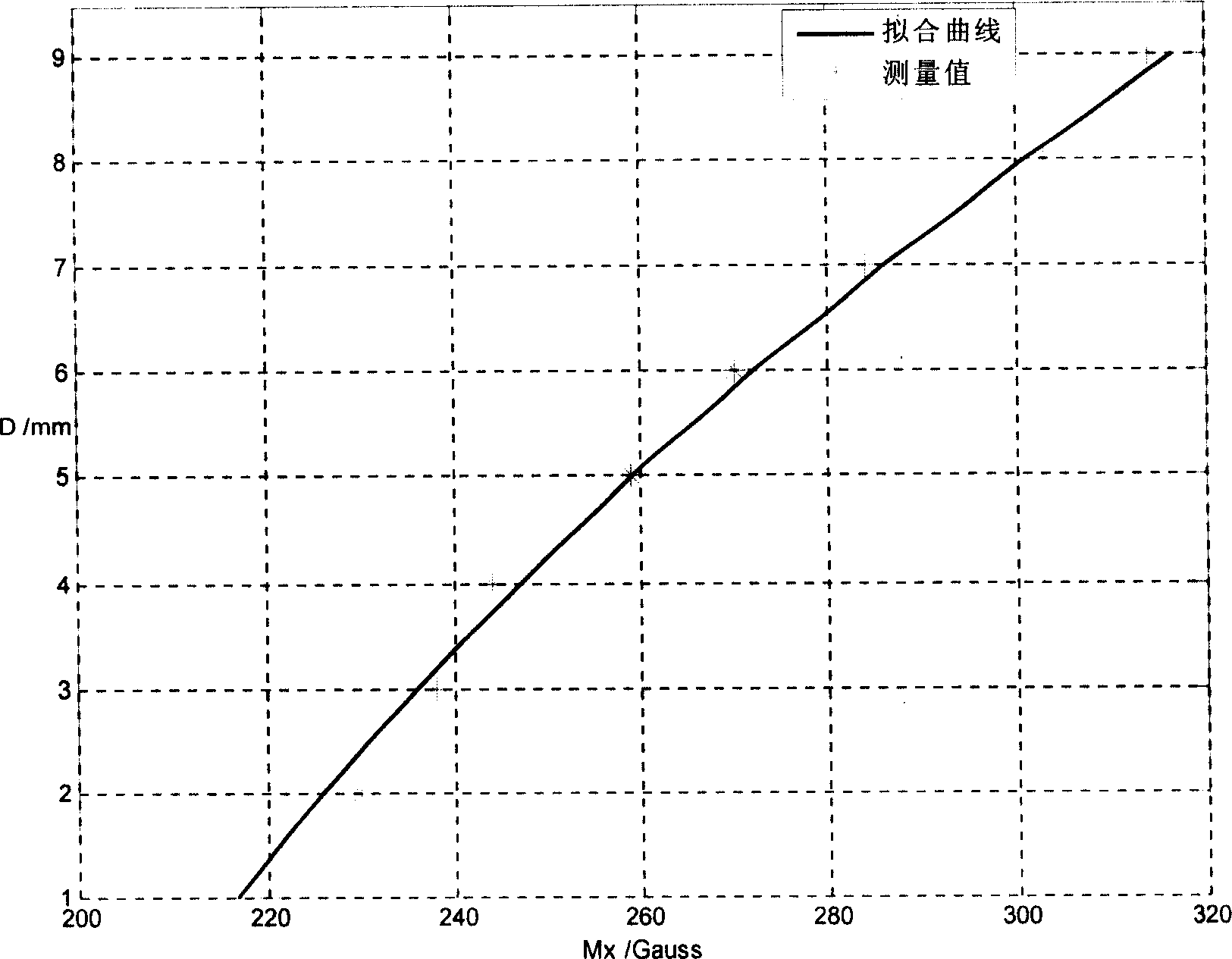

[0020] Before detecting pipeline corrosion defects, a standard defect detection experiment is carried out first. That is, take a standard pipe with a diameter of 273mm, a wall thickness of 10mm and the same material as the pipe to be tested, and process lengths on it of 10mm, 20mm, 30mm, 40mm, 50mm, 60mm, 70mm, 80mm, 90mm and 100mm , width is 30mm, depth is 2mm; length is 30mm, width is 10mm, 20mm, 30mm, 40mm, 50mm, 60mm, 70mm, 80mm, 90mm and 100mm, depth is 2mm; length and width are both 30mm, depth is 3 serie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com