Perambulated inspection system and method

The technology of a detection system and detection method, which is applied in the field of patrol detection system, can solve the problems of low accuracy of track defect size and low efficiency of track patrol detection, and achieve high detection accuracy of defect size, accurate positioning of track defects, and high detection efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

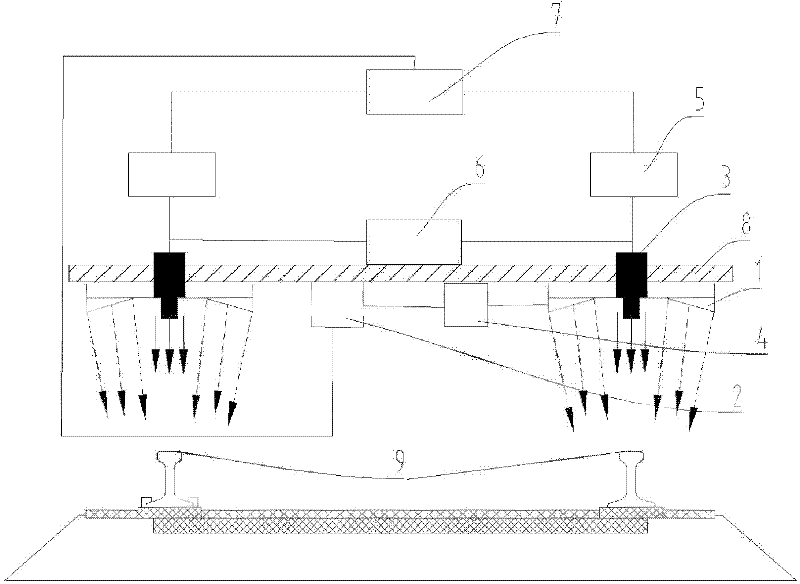

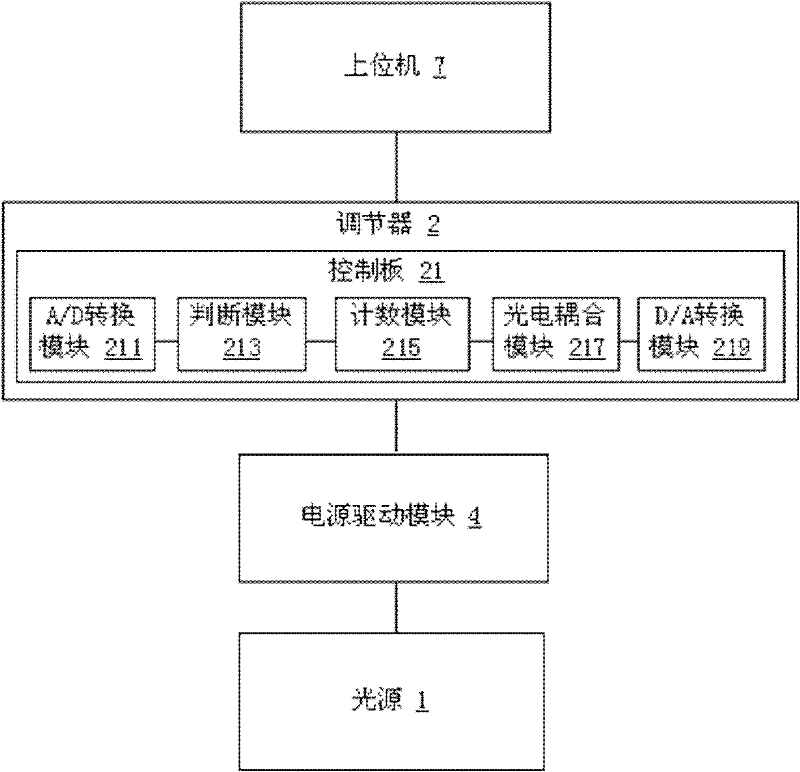

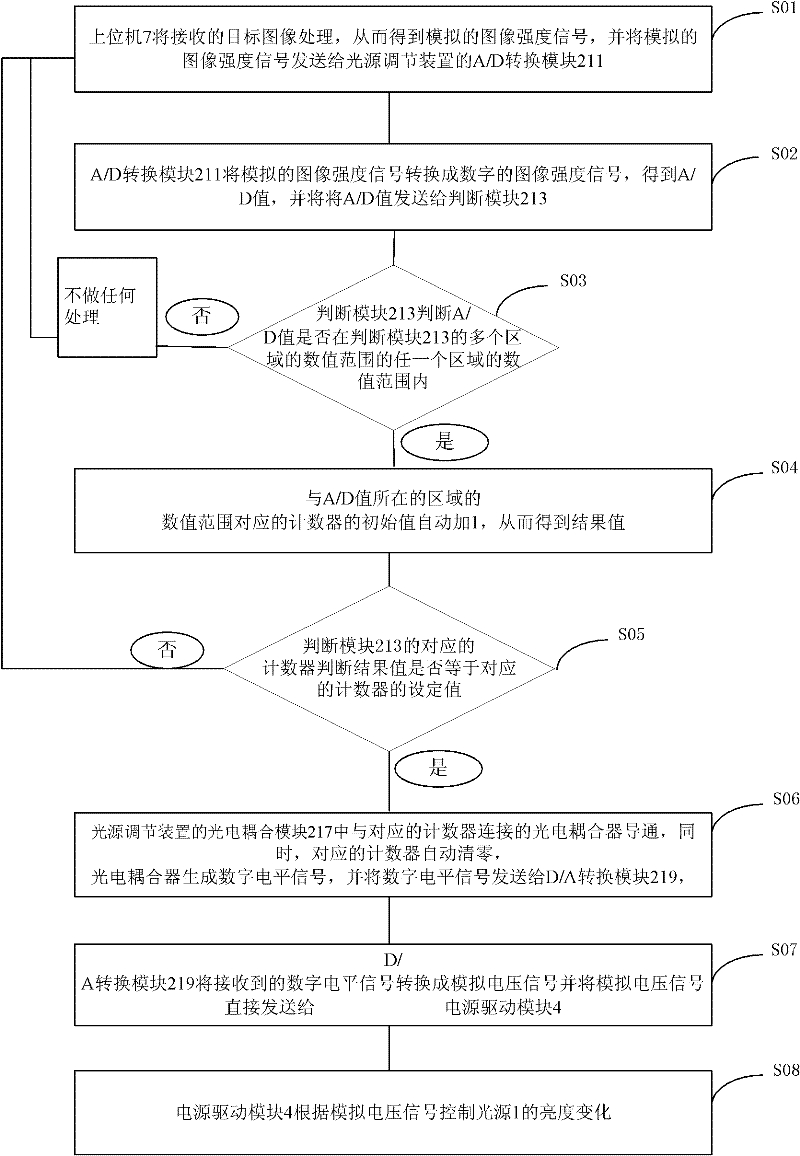

[0027] see figure 1 , the inspection inspection system includes a mounting frame 8 on which a plurality of light sources 1 and a plurality of cameras 3 located above the target 9 are symmetrically installed. Both the light source 1 and the camera 3 are connected with the host computer 7 . When the mounting frame 8 runs along the target object 9 at a certain speed, the light source 1 emits light to illuminate the target object 9; the camera 3 takes images of the target object 9 to obtain an image of the target object. Afterwards, the camera 3 sends the target image to the host computer 7, and the image processing system in the host computer 7 analyzes and processes the received target image.

[0028] In other embodiments, the mounting frame 8 is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com