Intelligent detection system for fault of railway wagon running part

A technology for railway freight car and intelligent detection, which is applied in the direction of railway vehicle testing, machine/structural component testing, measuring devices, etc. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

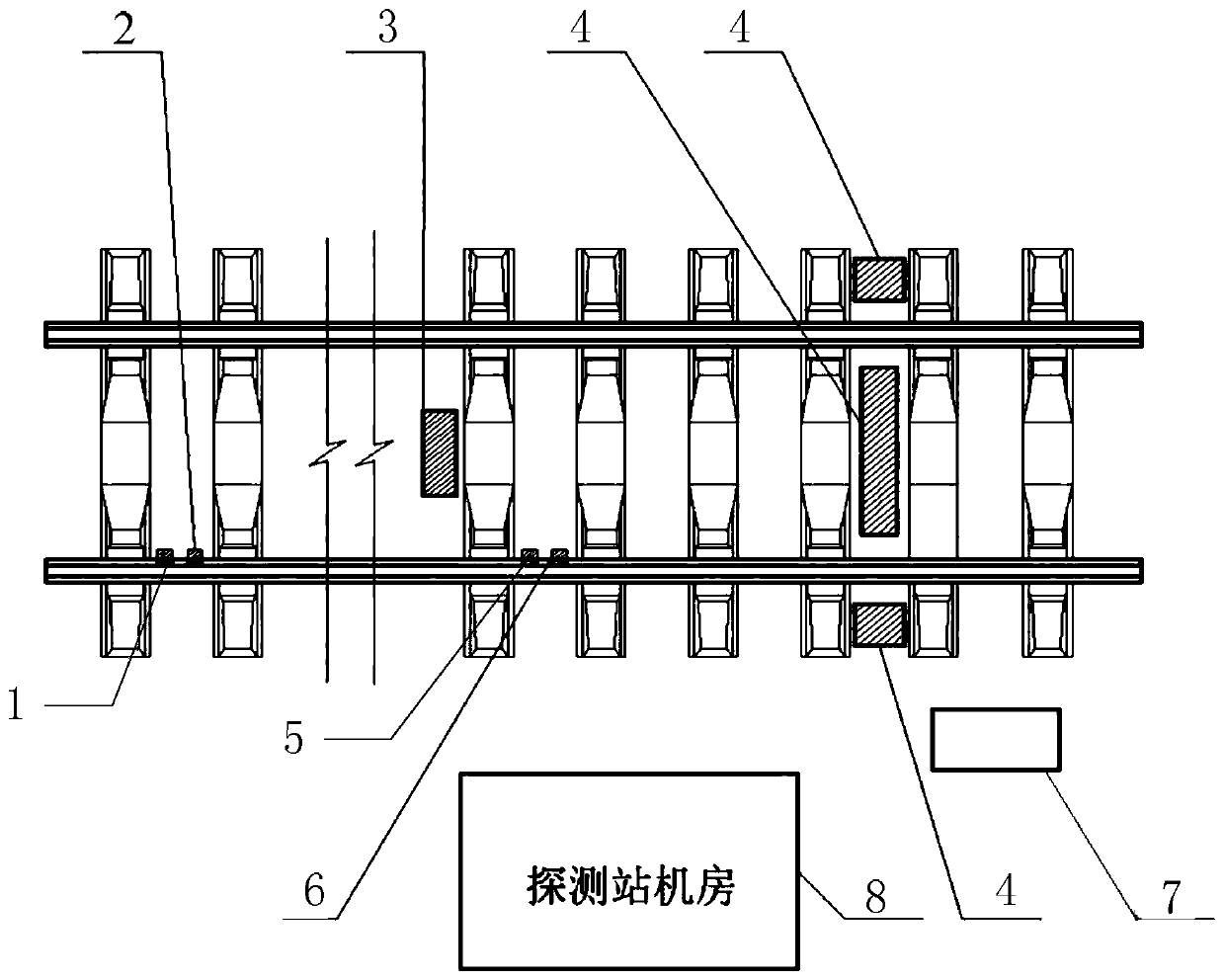

[0024] Specific implementation mode one: refer to figure 1 Describe this embodiment in detail, the railway freight car running part fault intelligent detection system described in this embodiment, the system includes No. 1 wheel sensor 1, No. 2 wheel sensor 2, No. 3 wheel sensor 5 and No. 4 wheel sensor 6, radio frequency Reading device 3, 3 groups of image acquisition devices 4, control unit, image storage unit and automatic fault identification unit,

[0025] The distance between the No. 1 wheel sensor 1 and the No. 2 wheel sensor 2 is 200mm-400mm, both of which are installed on the inner wall of the track in the direction of the vehicle to detect the pulse signal of each wheel,

[0026] The distance between the No. 3 wheel sensor 5 and the No. 4 wheel sensor 6 is 200mm-400mm, and they are all installed on the inner wall of the track to detect the pulse signal of each wheel.

[0027] The control unit is used to obtain the driving speed of the vehicle according to the time d...

specific Embodiment approach 2

[0041] Specific embodiment 2: This embodiment is to further explain the fault intelligent detection system for the running part of railway freight cars described in specific embodiment 1. In this embodiment, the system also includes 1 trackside caisson and 2 trackside sides box,

[0042] A trackside caisson is arranged between the two tracks, and a set of image acquisition equipment 4 is placed in the trackside caisson;

[0043] The two trackside side boxes are respectively arranged on the outside of the two tracks, and one set of image acquisition equipment 4 is placed in each of the two trackside side boxes.

[0044] In this embodiment, three groups of image acquisition devices 4 are placed in the caisson and the trackside side box respectively, and the control unit, image storage unit and automatic fault identification unit are all placed in the detection station machine room. Protect the instrument so that the system can work normally even in environments such as sand, du...

specific Embodiment approach 3

[0045] Specific embodiment 3: This embodiment is to further explain the fault intelligent detection system of the running part of the railway freight car described in the specific embodiment 1. In this embodiment, the system also includes a junction box 7,

[0046] A compensation light source power supply module is arranged in the junction box 7 for providing compensation light sources to the three groups of image acquisition devices 4 according to the control signal output by the control unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com