Air conditioner side plate inspection tool

A side plate and air-conditioning technology, applied in the direction of mechanical diameter measurement, etc., can solve the problems of unrecognized leaks by human eyes, low detection efficiency, aperture leakage detection, etc., to reduce the probability of rework in subsequent processes, improve production efficiency, and reduce non-compliance rates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is further described in conjunction with the following examples.

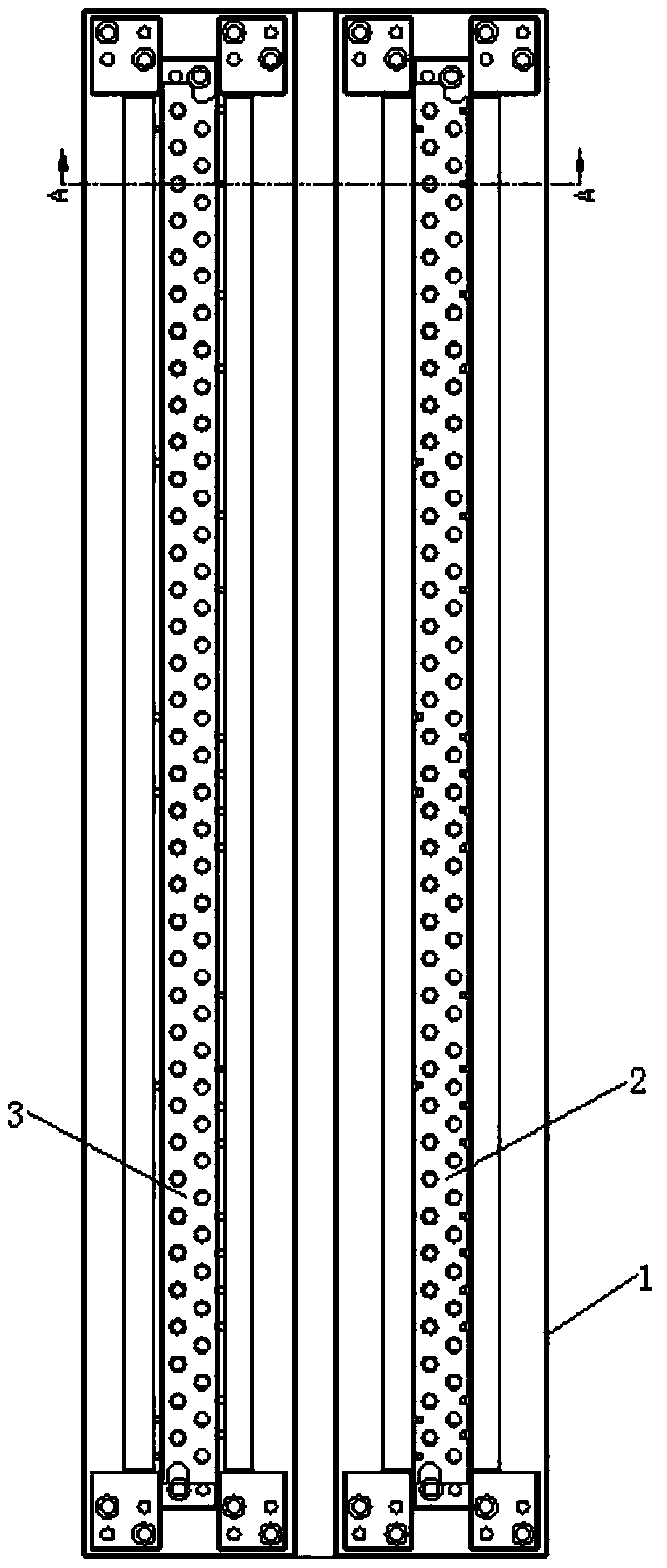

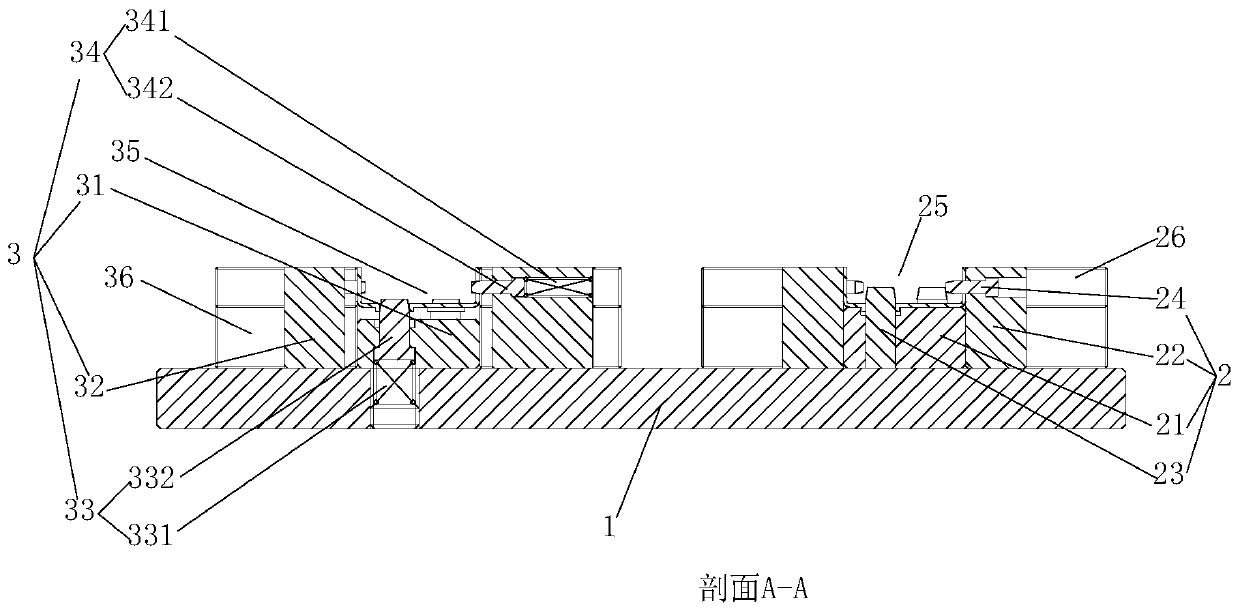

[0038] Such as figure 1 with figure 2 , an air conditioner side panel inspection tooling, comprising a base 1, a through-regulation inspection tooling set 2 and a stop-gauge inspection tooling set 3. Among them, the general inspection tooling group 2 is set on the base 1 and is used to test the front aperture and side aperture of the air conditioner side panel; the stop gauge inspection tooling group 3 is arranged on the base 1 and is located in the general inspection tooling group 2, and is used to inspect the front and side apertures of the air-conditioning side plate after the general inspection tooling group 2 has passed the inspection of the air-conditioning side plate.

[0039] The air-conditioning side plate inspection tool is combined with the through-rule inspection tooling group 2 and the stop-gauge inspection tooling group 3, and the through-rule inspection tooling gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com