Intelligent analysis system and method for magnetic flux leakage detection data in pipeline

A technology of intelligent analysis and data, applied in pipeline systems, electrical digital data processing, special data processing applications, etc. Analytical system view and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0162] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

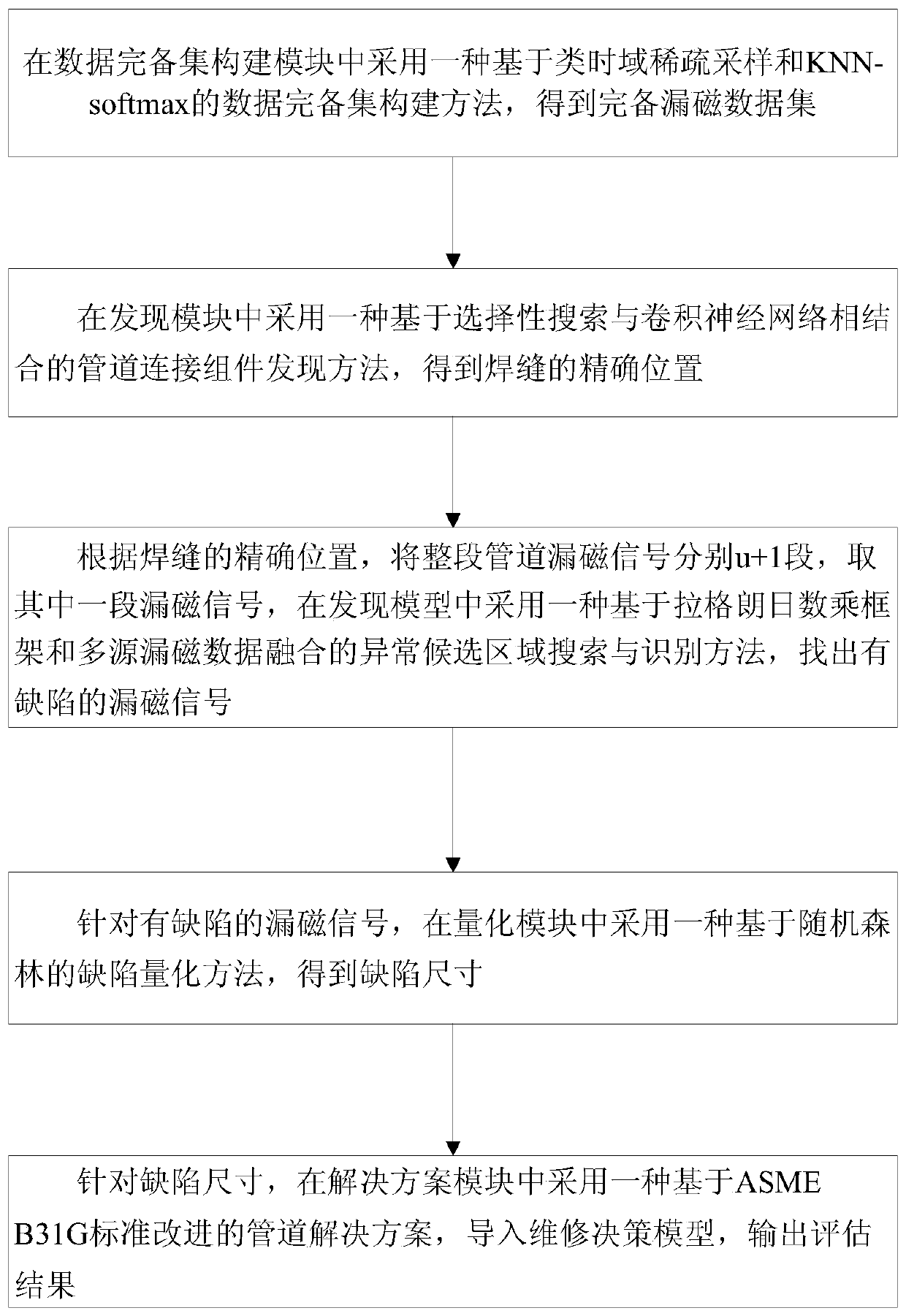

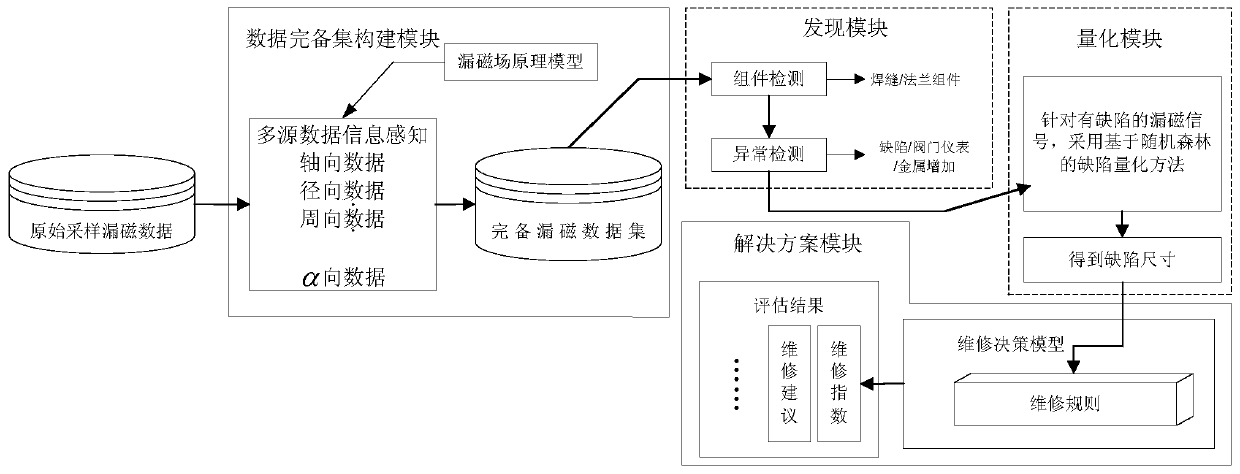

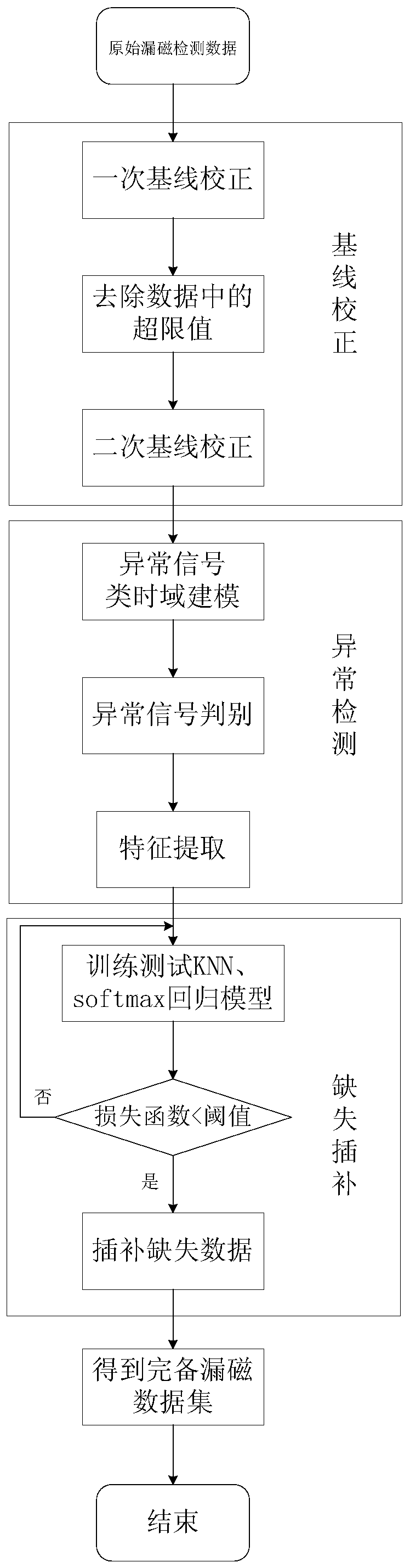

[0163] The invention provides a software system and method for intelligent analysis of magnetic flux leakage data detected in pipelines. It proposes an internal detection magnetic flux leakage data analysis system from the perspective of non-destructive testing and evaluation as a whole, and invents a method based on time-like sparse sampling and KNN- A softmax data complete set construction method, a pipeline connection component discovery method based on the combination of selective search and convolutional neural network, an anomaly candidate region search and Identification method, a defect quantification method based on random forest and an improved pipeline solution based on ASME B31G standard. Realize the safe operation and maintenance of the pipeline.

[0164] Such as figure 2 As shown, it is a system diagram of the magnetic flux leakage data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com