Frequency characteristic-based nondestructive detection method of stress waves of wood

A frequency characteristic, non-destructive testing technology, applied in the processing of the detected response signal, the use of sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problem of large errors in the detection results, without considering the reflection, refraction, transmission, and mixed reflected waves of the stress wave signal , refracted wave signal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

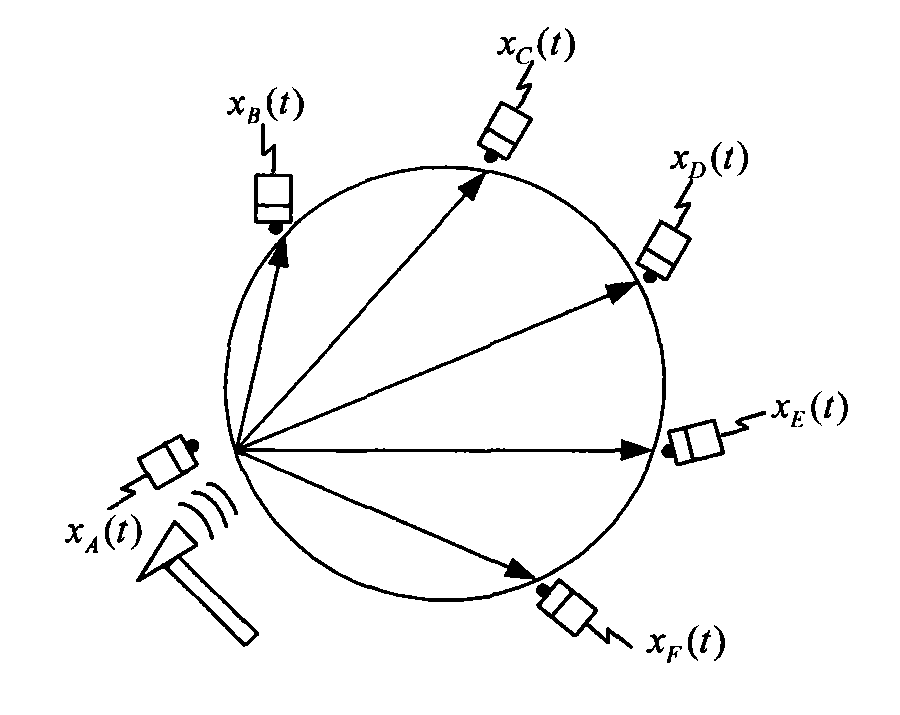

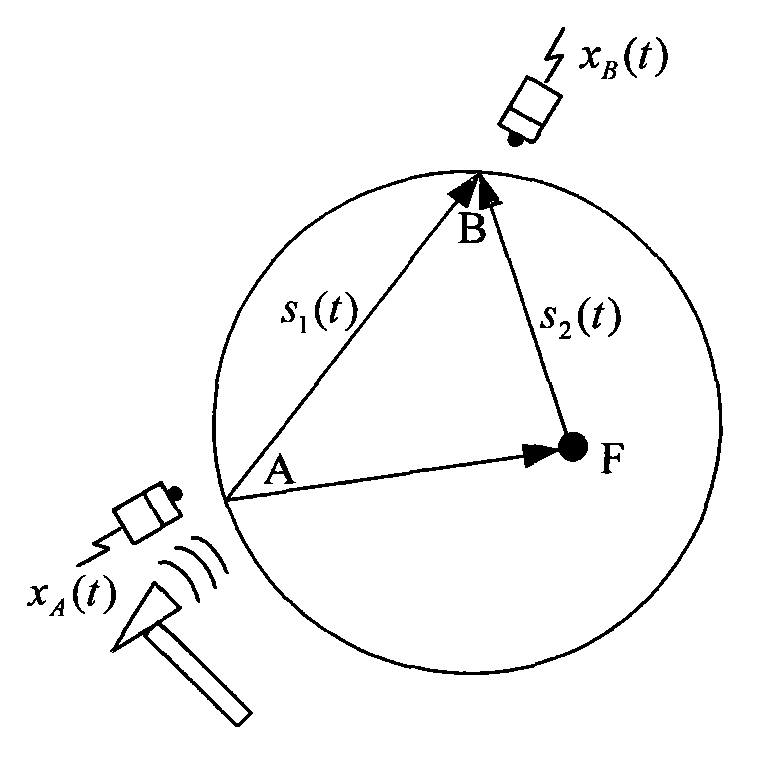

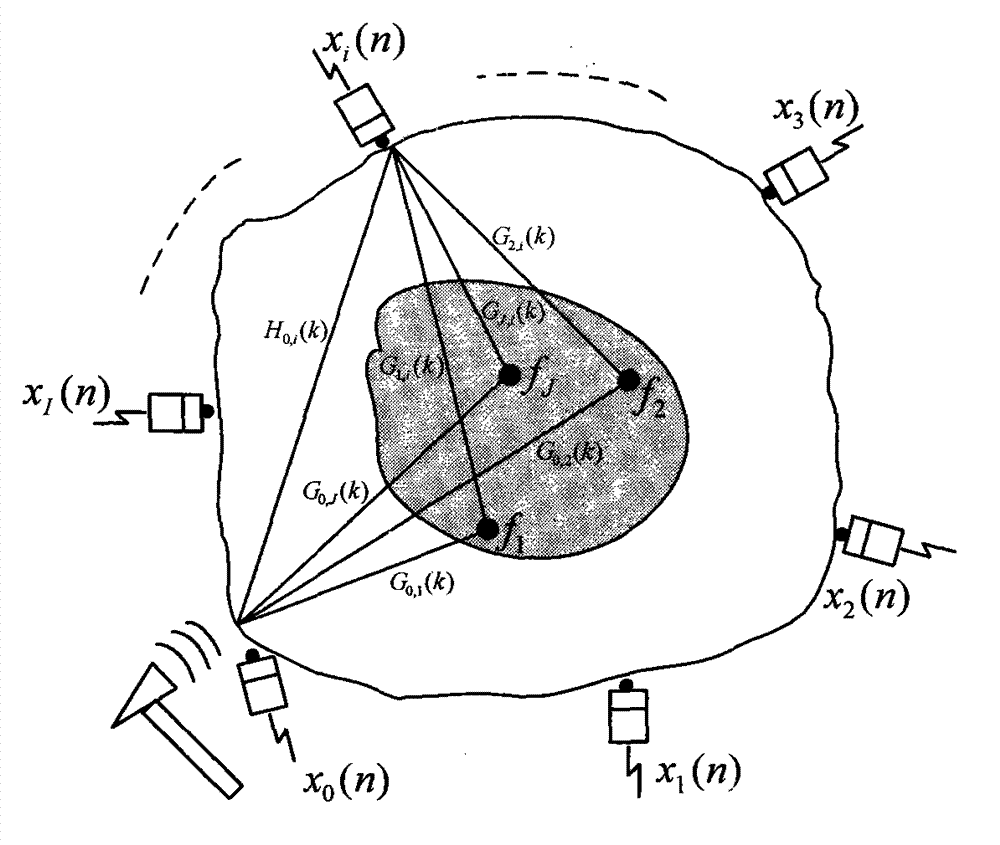

[0057] A specific embodiment of the present invention is: a method for nondestructive detection of wood stress waves based on frequency characteristics, the specific method is:

[0058] Step 1: Install six piezoelectric acceleration sensors evenly around the log, and the output signal of the acceleration sensor is connected to the data acquisition card through the charge amplifier. The wiring diagram is as follows Figure 4 shown. see image 3 , use a pulse hammer to hit the 0th sensor, and the 6 sensors convert the received stress wave signal into an electrical signal and input it into the data acquisition card. Complete data conversion and other work under the control of the host computer software, and record the signal x 0 (n),x 1 (n),x 2 (n),x 3 (n),x 4 (n),x 5 (n). Select the sampling period as 1μs, and the recording signal length as 10ms.

[0059] Step two, for x 0 (n),x 1 (n),x 2 (n),x 3 (n),x 4 (n),x 5 (n) Do fast Fourier transform, select 1024 transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com