Safety evaluating method of pressure equipment containing crack defects

A technology of pressure-bearing equipment and defects, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of complicated selection 3, low evaluation accuracy, and difficult to achieve, and achieve the effect of avoiding complex finite element simulation.

Inactive Publication Date: 2011-02-16

EAST CHINA UNIV OF SCI & TECH

View PDF4 Cites 37 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to overcome the problems that selection 1 and selection 2 FAD technology ignores the influence of defect size, the evaluation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

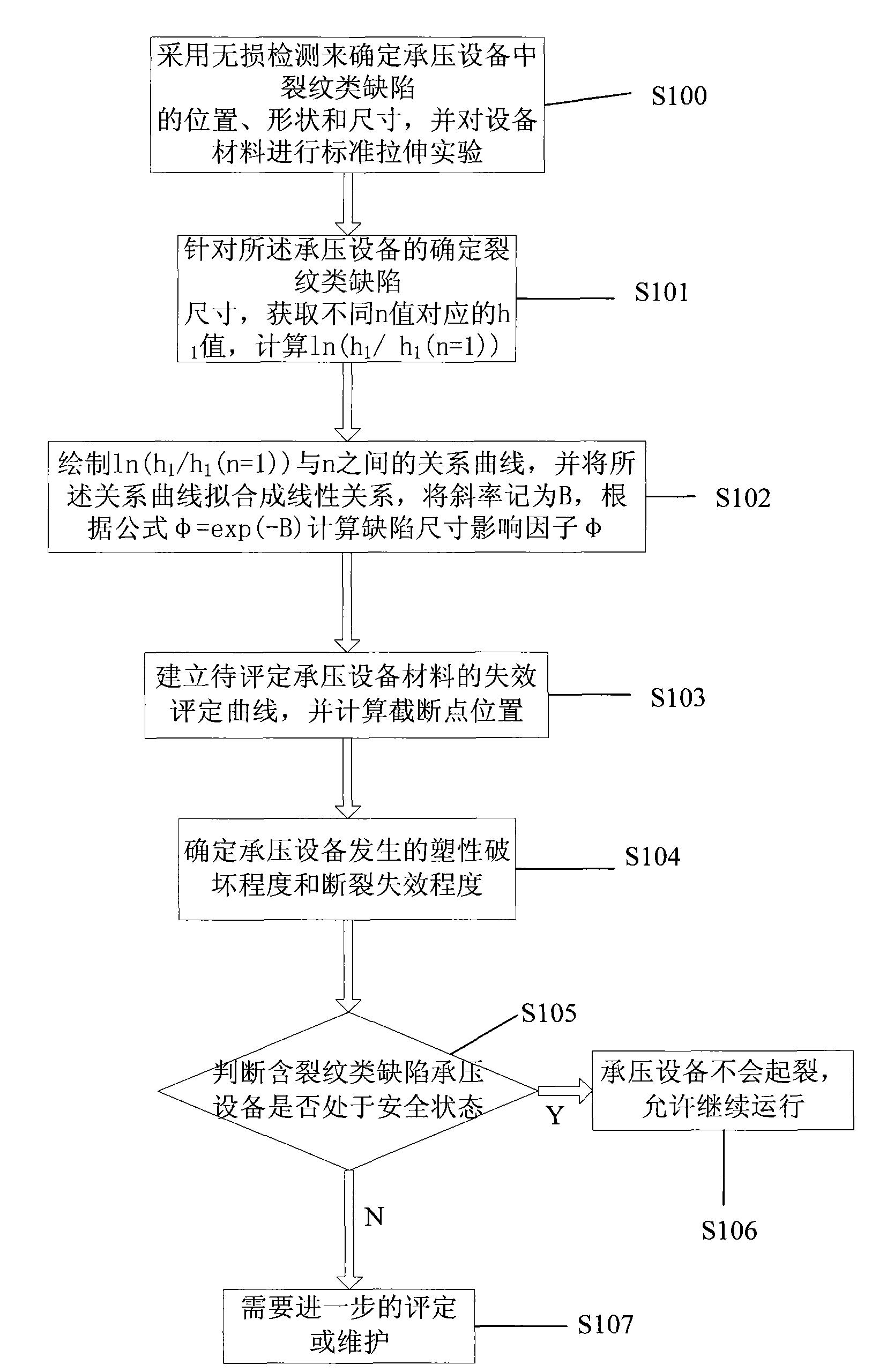

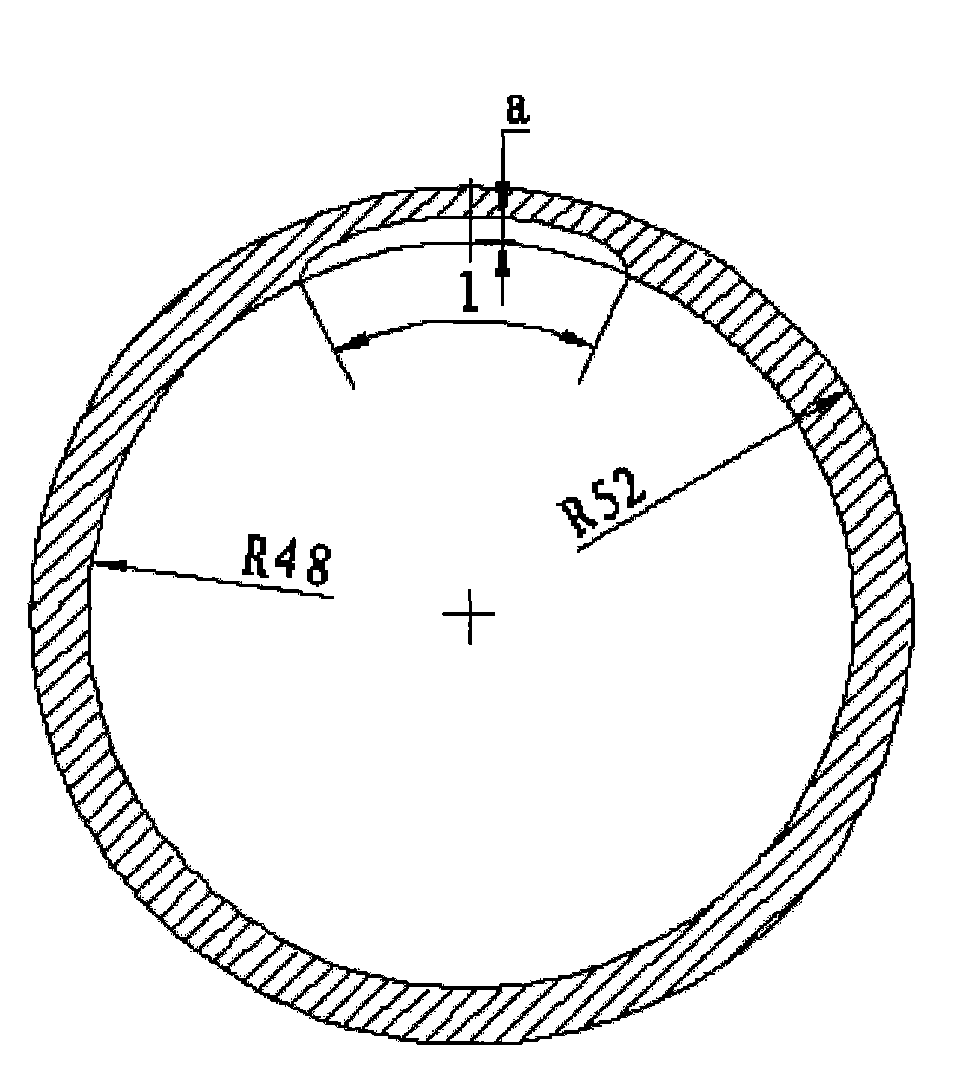

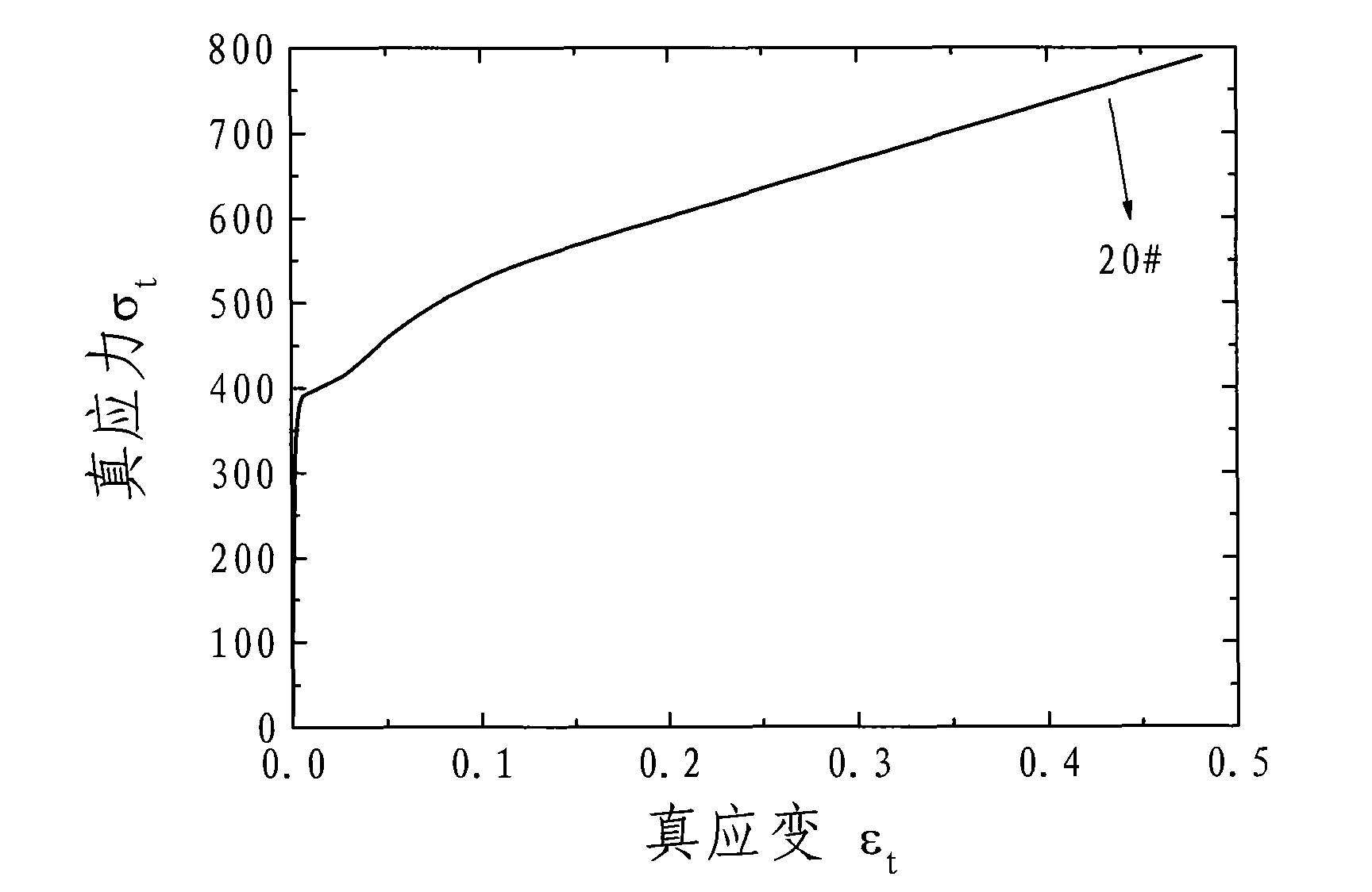

The invention discloses a safety evaluating method of pressure equipment containing crack defects, which comprises the following steps: 1, carrying out nondestructive testing and a standard stretching experiment; 2, obtaining a fully plastic solution factor h1 corresponding to the hardenability value n of different materials, and computing 1n(h1/h1(n=1)), wherein h1(n=1) is the value of h1 when nis equal to 1; 3, drawing a relationship curve between (h1/h1(n=1)) and n, fitting the relation curve into a linear relationship, recording the slope rate as B, and computing a defect size influence factor phi according to the formula phi=exp(-B), wherein exp presents an exponential function using a natural logarithm e as a base index; 4, establishing a failure evaluating curve and computing the positions of discontinuities; and 5, determining the plastic damage extent L'r and the fracture failure extent K'r of the pressure equipment, and judging the safety state of the pressure equipment containing the crack defects. In the method of the invention, the influence of the defect size factor phi to the safety is considered so that the evaluation is more accurate; phi is not limited by the material parameter n so that the invention can be simply and easily used for computing any materials.

Description

technical field [0001] The invention relates to a safety assessment method, in particular to a safety assessment method for pressure-bearing equipment containing crack defects, such as pressure vessels and pressure pipelines. Background technique [0002] Pressure equipment is a general term for equipment with fluid pressure as the basic load, such as pressure vessels, pressure pipes, pressure accessories, and pressure boilers. Widely used in petroleum, chemical, food, pharmaceutical, aerospace, energy and other fields. Because the service conditions of these pressure equipment vary widely, there are high temperature, low temperature, cryogenic; there are ultra-high pressure, high pressure, medium pressure, low pressure and vacuum; Equipment in production inevitably has defects of varying degrees. Therefore, once the equipment leaks or explodes, serious damage will occur, which will not only cause economic losses, but also cause serious environmental pollution. Among the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08

Inventor 刘长军张静轩福贞惠虎李培宁王国珍谈建平

Owner EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com