Ultrasonic guided-wave based calculation method for separating flexural mode reflected signal

A technology of bending mode and ultrasonic guided wave, which is applied in the direction of processing the response signal of detection, etc., to achieve the effect of high accuracy of results, saving manpower, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

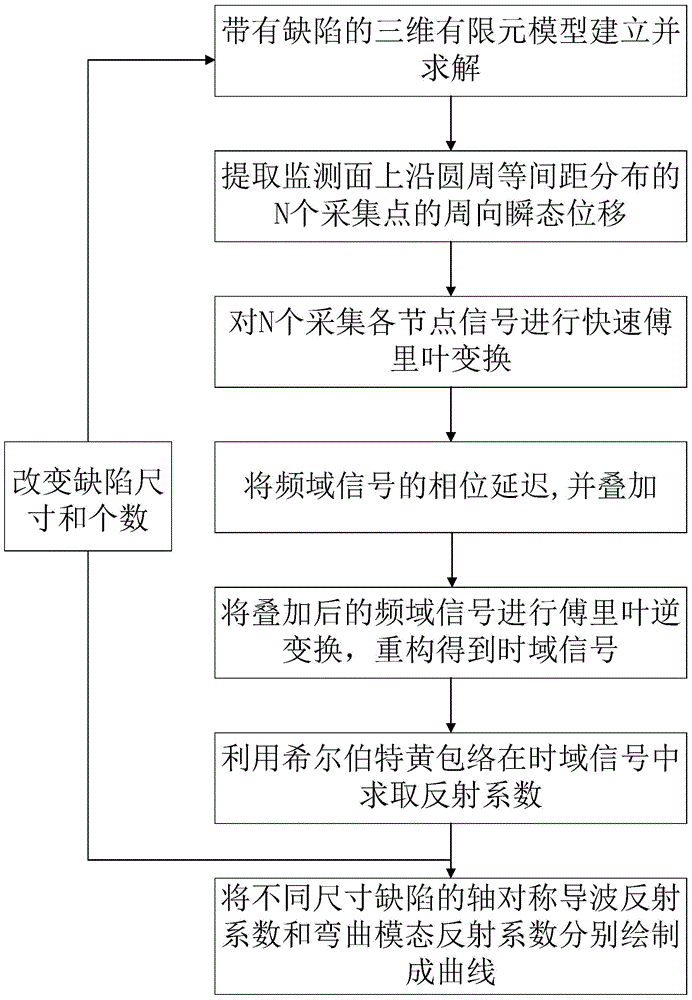

[0033] In conjunction with the content of the method of the present invention, the calculation method example of the following double-hole defect T (0, 1) mode and bending mode reflection coefficient in the pipe is provided, and the specific steps are as follows: figure 1 Shown:

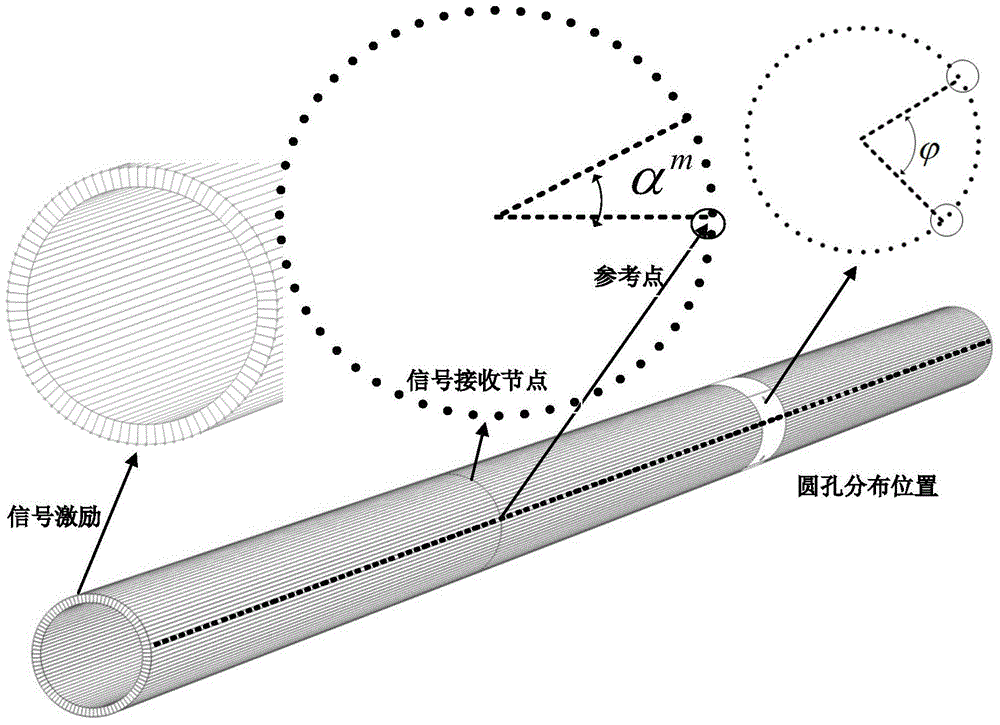

[0034] 1) Build as figure 2 The three-dimensional pipeline model shown has a model length of 3000mm, an outer diameter of 76.2mm, a wall thickness of 5.5mm, a ratio of diameter to thickness of 13.85, and a density of 7843kg / m 3 , Young's modulus is 210GPa, Poisson's ratio is 0.28; 90 excitation nodes are set on the outer ring of the pipe end; at a distance of 2000mm from the signal excitation end, circular hole defects distributed in the circumferential direction are set, and the diameter of the circular hole is 5.5mm, the angle between the centers of the two circular holes must be greater than 10 degrees; the distance between the signal monitoring surface and the defect center is 1000mm, and 90 equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com