Gas turbine blade defects extraction and analysis method based on region segmenting detection

A gas turbine blade and region segmentation technology, which is applied to the use of radiation for material analysis, etc., can solve problems such as heavy workload, high operating cost, and complicated detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below with reference to the drawings and embodiments.

[0058] The gas turbine blade defect extraction and analysis method based on region segmentation detection includes the following steps:

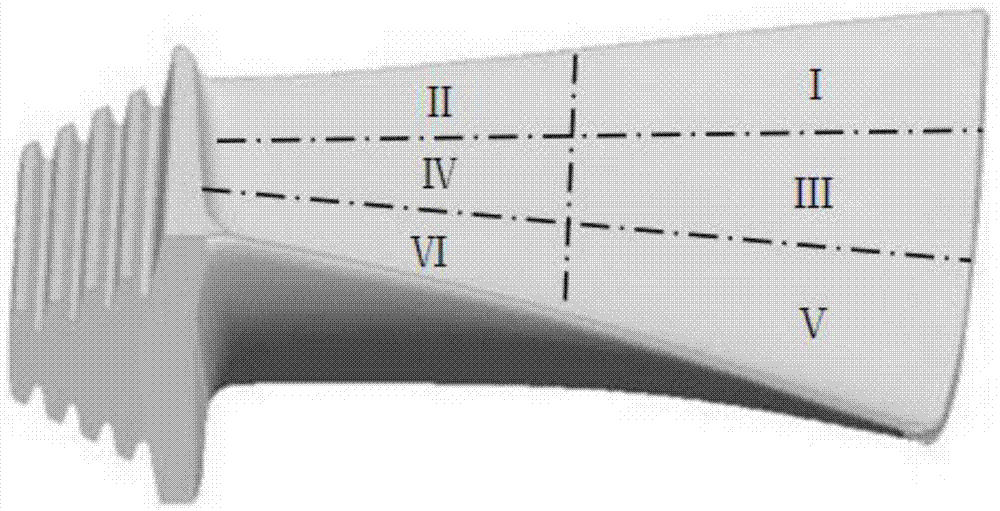

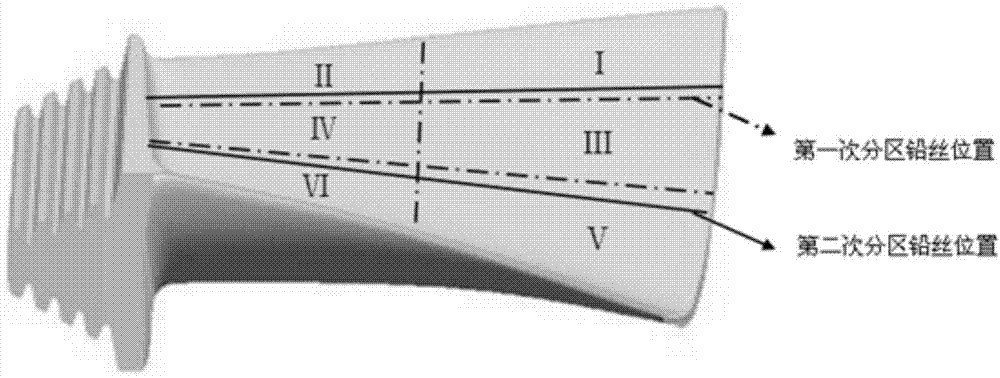

[0059] 1) Due to the irregularity of the shape of the gas turbine blade, the unevenness of the thickness and the size limitation of the flat panel detector, it is necessary to use different transmission powers and different exposure times for different positions of the gas turbine blades. Partition inspection, each area needs to be inspected with appropriate exposure parameters. Larger and smaller exposure parameters will affect the imaging quality of digital radiography, so first, according to the size and thickness of the blade, the blade is divided into 6 areas with lead wire Carry out zoning inspection, such as figure 1 As shown, the black dotted line is the location of the lead wire. Because the lead wire can absorb X-rays well, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com