Multi-source data fusion-based system and method for predicting pipeline corrosion defect size

A defect size, multi-source data technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of reduced accuracy, low prediction accuracy, and difficulty in obtaining sufficient testing data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] An embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

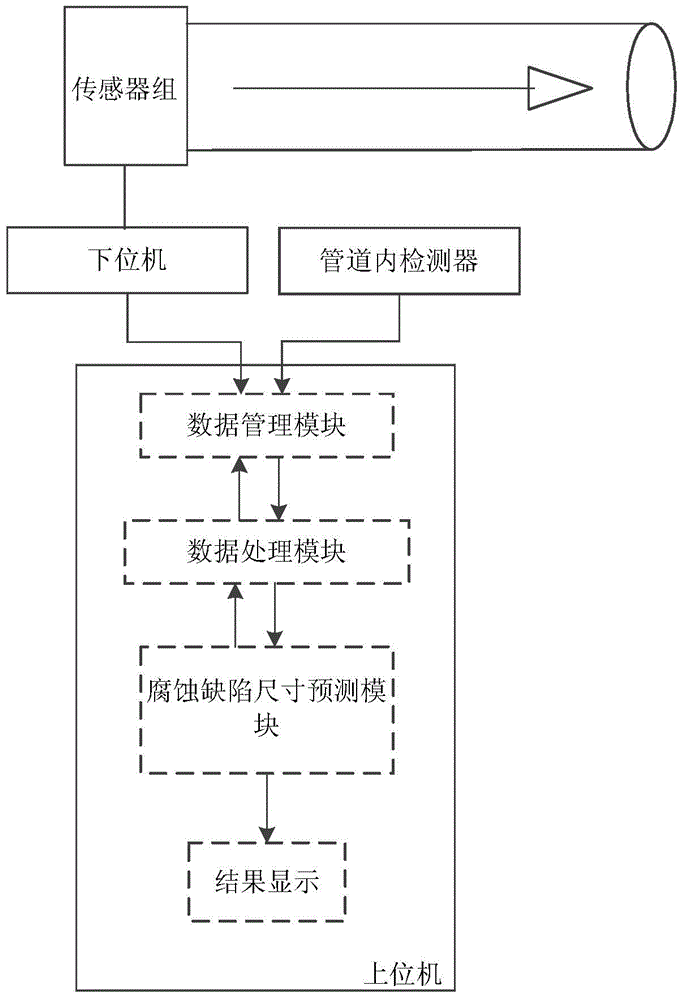

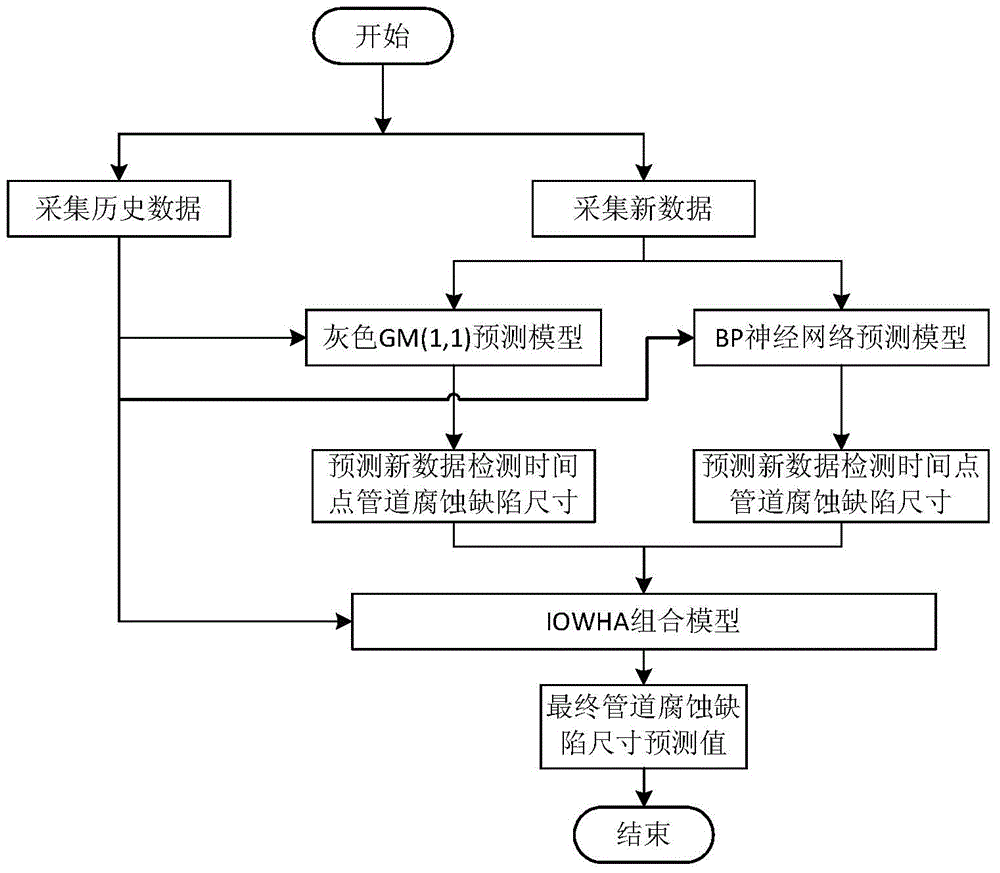

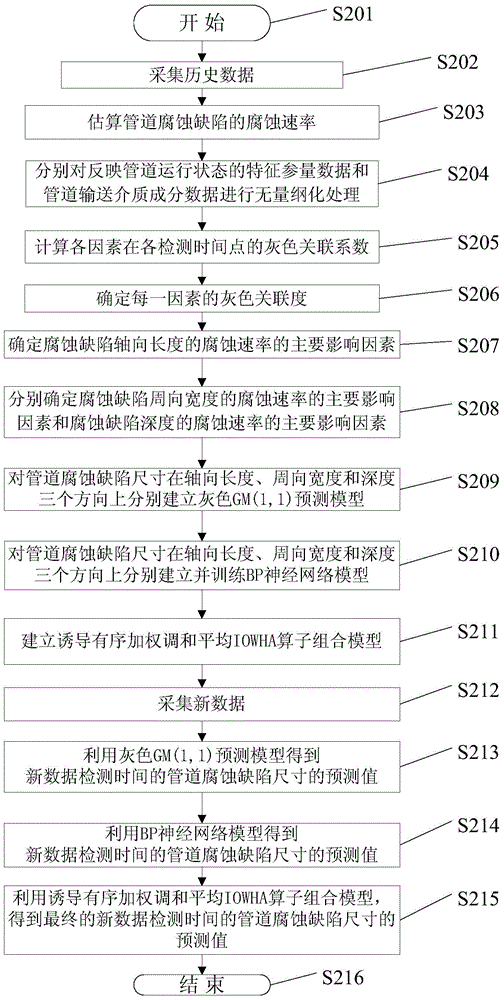

[0060] The prediction system of pipeline corrosion defect size based on multi-source data fusion in this embodiment, such as figure 1 As shown, it includes a sensor group, a lower computer and an upper computer; the sensor group is placed at the head or end of the pipeline and is in contact with the conveying medium. The sensor group includes a variety of sensors, which are used for real-time collection and reflection of the pipeline operating status The characteristic parameter data and the composition data of the pipeline transportation medium, and transmit these data to the lower computer; the types and quantities of the various sensors are determined according to the actual use of the pipeline type and pipeline transmission medium; this embodiment uses a diameter of 219mm, wall A steel pipe with a thickness of 9.5 mm is used for the simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com