Casting polishing quality test method and device and application method of device

A quality inspection method and casting technology, which are used in measuring devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve problems such as insufficient grinding and low quality inspection efficiency, improve image quality, and the method is simple and stable. Reliable, extended grayscale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

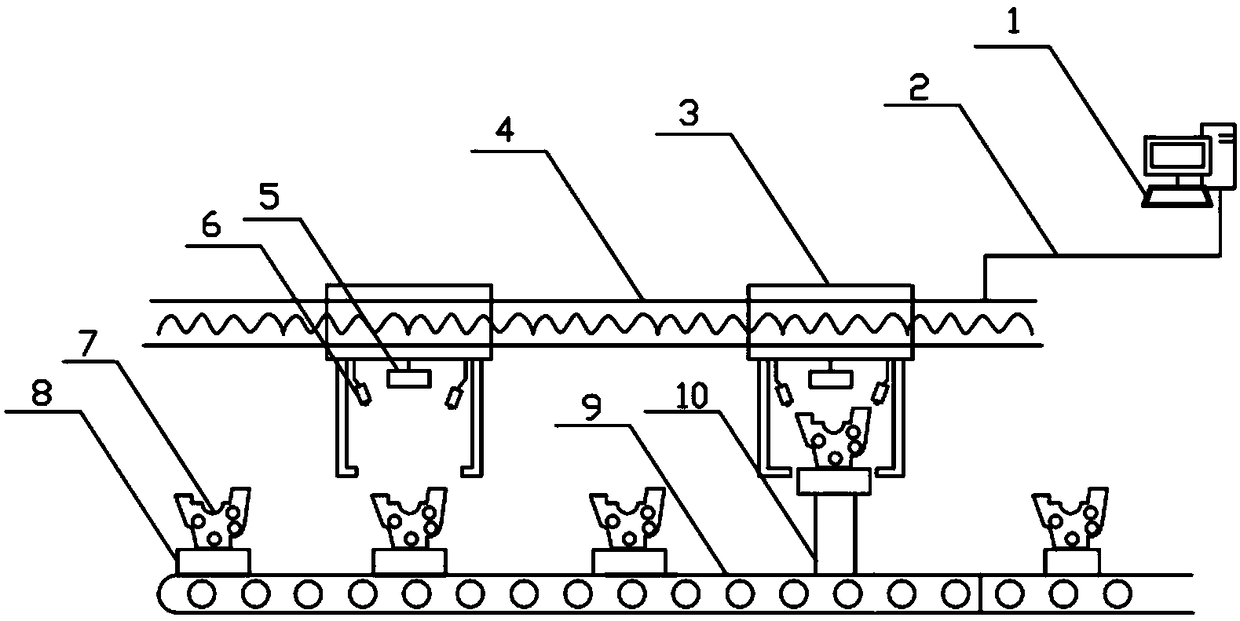

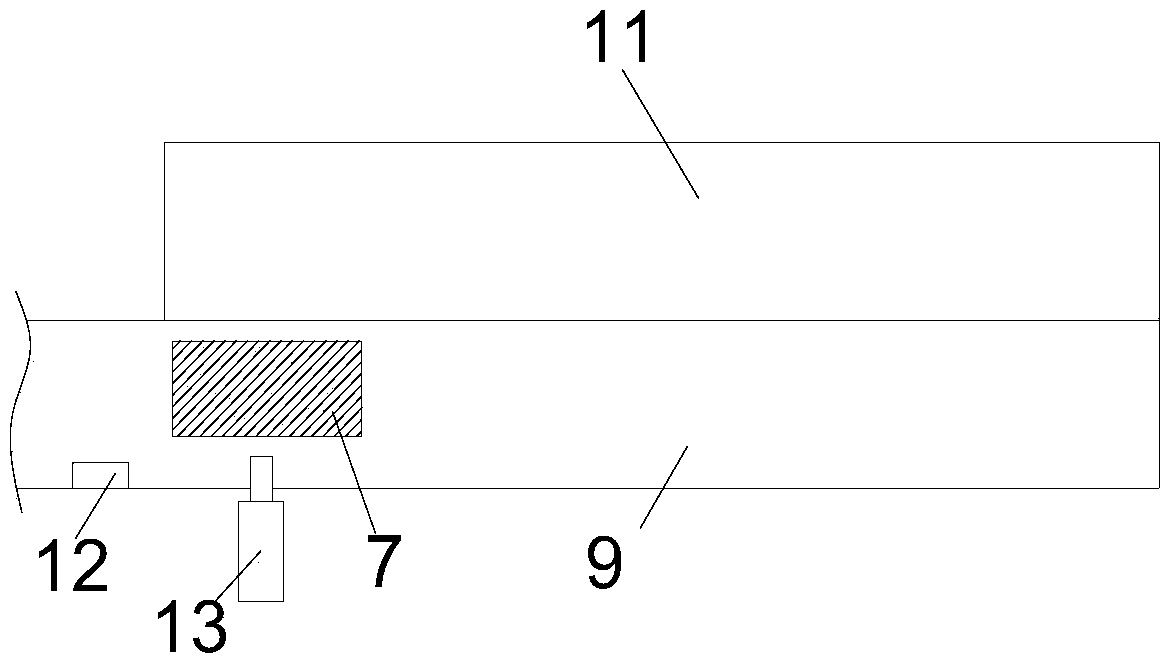

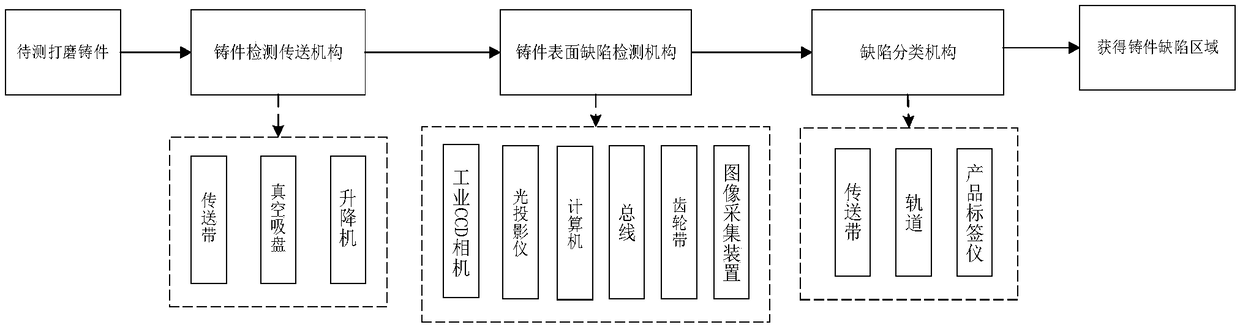

[0050] see figure 1 , a quality inspection device for casting grinding, comprising 1, a computer; 2, a bus; 3, an image detection area mounting frame; 4, a gear belt; 5, an industrial CCD camera; 6, an optical projector; 7, a casting; 8, Vacuum sucker; 9. Conveyor belt; 10. Elevator. The vacuum chuck 8, the conveyor belt 9 and the elevator 10 constitute a transmission structure, the main function of which is to fix the just polished casting 7 on the vacuum chuck 8 according to the specified direction and position, and the vacuum chuck 8 is distributed and connected to the conveyor belt 9 at a certain distance. of the top.

[0051] During operation, the vacuum chuck 8 carries the casting 7 and moves slowly on the conveyor belt 9 for the purpose of moving the measured casting to the bottom of the image acquisition area device 3. At this time, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com