A visual fracture device and working method for simulating fracture closure and fluid loss

A technology for simulating cracks and fractures, applied in the field of simulated and visualized fracture devices, can solve the problems of inaccurate experimental results and inability to simulate repeated fracturing, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

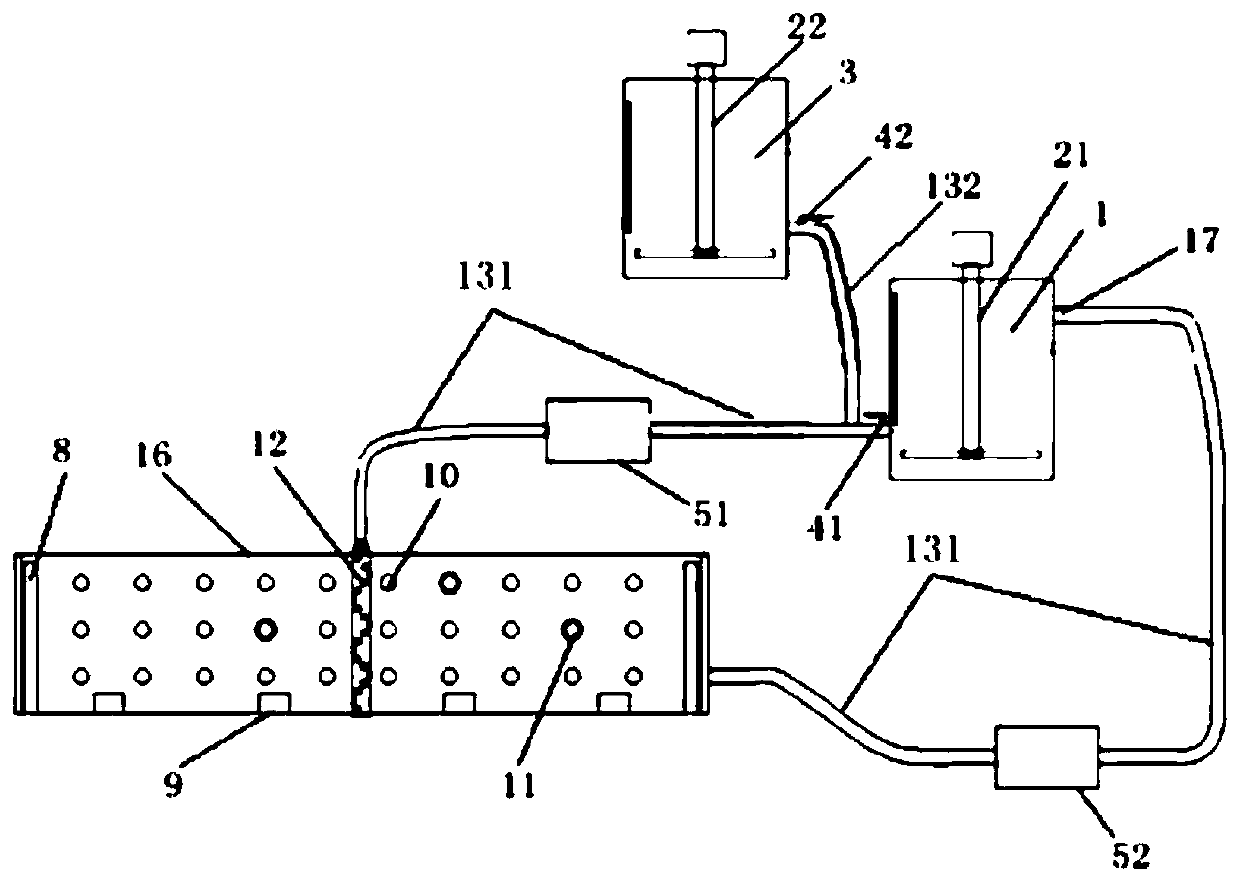

[0057] Such as figure 1 As shown, a visualized fracture device for simulating fracture closure and fluid loss in this embodiment includes a fracturing fluid tank 1 , a sand mixing fluid tank 3 , a fracturing fluid pump 51 , a visualized fracture simulation plate 16 and a drainage pump 52 . Wherein, the discharge port of the fracturing fluid tank 1, the fracturing fluid pump 51, the visualized fracture simulation plate 16, the drainage pump 52, and the circulating feed port 17 of the fracturing fluid tank are connected through the main fracturing pipeline 131 to form a circulation loop, The outlet of the sand mixing fluid tank 3 is connected to the main fracturing pipeline 131 located between the fracturing fluid pump 51 and the outlet of the fracturing fluid tank 1 through a branch line 132 . The fracturing fluid tank 1 and the sand mixing fluid tank 3 are respectively connected to the fracturing fluid pump 1 through a three-way joint. The circulation loop of the whole device...

Embodiment 2

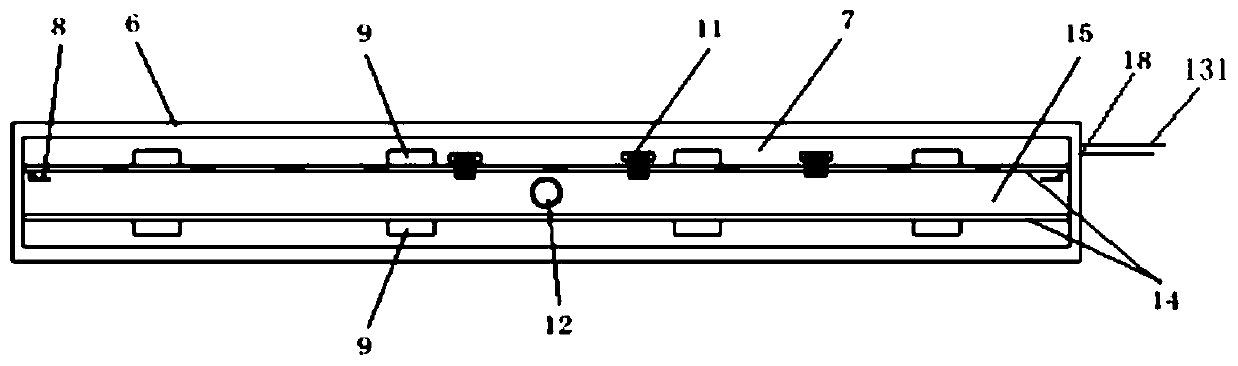

[0065] The difference between the structure of this embodiment and Embodiment 1 lies in the wall surface. The wall surface of this embodiment includes an artificial wall surface simulating a real rock formation, which is used to simulate the influence of the real lithologic reservoir wall surface on the movement law of proppant. Wall surface clamping grooves 8 are provided at both ends of the flat plate 14 with the filtration holes 10 for installing artificially made crack walls.

Embodiment 3

[0067] Using the working method of a visualized fracture device for simulating fracture closure and fluid loss in Example 2, according to the slug type fracturing process, the steps are as follows:

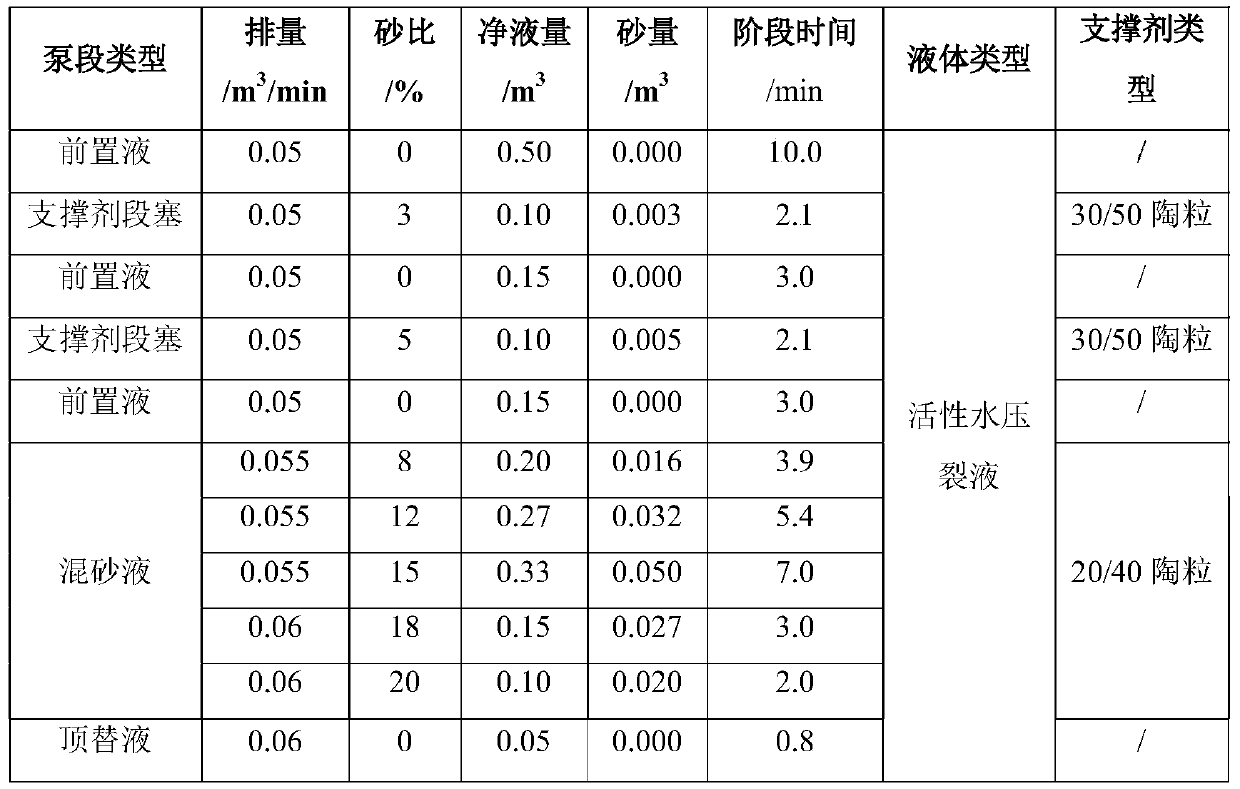

[0068] (1) According to the principle of similarity, according to the three-dimensional size of the fracture in the field construction, the viscosity of the fracturing fluid required for the experiment is calculated to be 20mPa·s, and the proppant dose is 0.15m 3 , fracturing fluid volume 2.1m 3 , Experimental displacement 0.05 ~ 0.06m 3 / min, the number of perforation holes is 16 / m, and the slug time is 4.2min, and the slug fracturing pump injection program is designed, as shown in Table 1;

[0069] (2) Prepare active water fracturing fluid and 30 / 50 and 20 / 40 ceramic proppant according to the required proppant amount and fracturing fluid volume calculated in step (1), and configure fracturing fluid and sand mixing fluid, which will be used as The fracturing fluid of the pad fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com