Method for determining characteristic stress in rock material damage evolution process based on energy analysis

A technology for rock material and energy analysis, applied in the direction of analyzing materials, using stable tension/pressure to test material strength, and using repetitive force/pulse force to test material strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

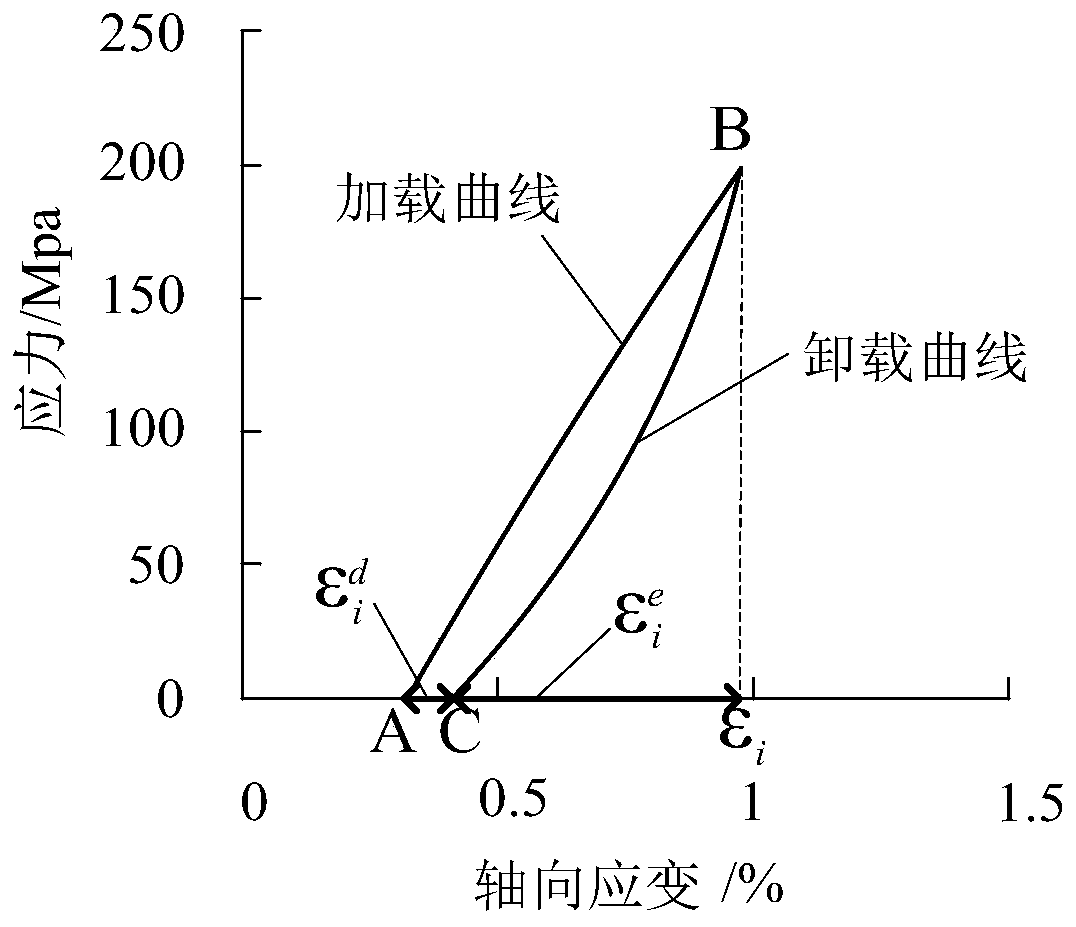

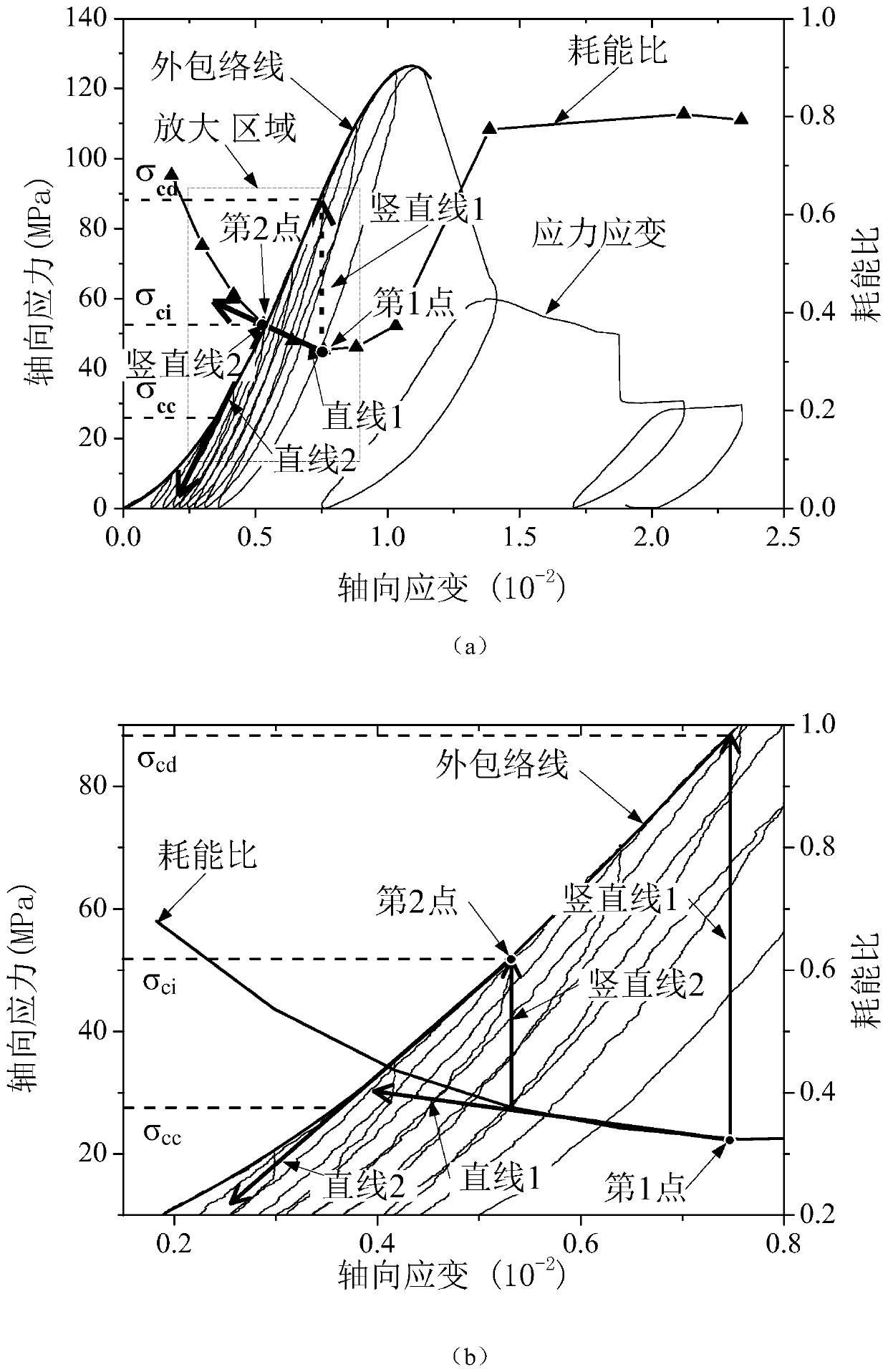

[0043] The method for determining the characteristic stress in the process of rock material damage evolution based on energy analysis of the present invention comprises the following steps:

[0044] (1) On-site drilling of complete cores;

[0045] (2) The above-mentioned rock core is processed in the laboratory to prepare a cylindrical sample with a diameter of 50mm and a height of 100mm;

[0046] (3) divide the prepared cylindrical sample into two groups of A and B;

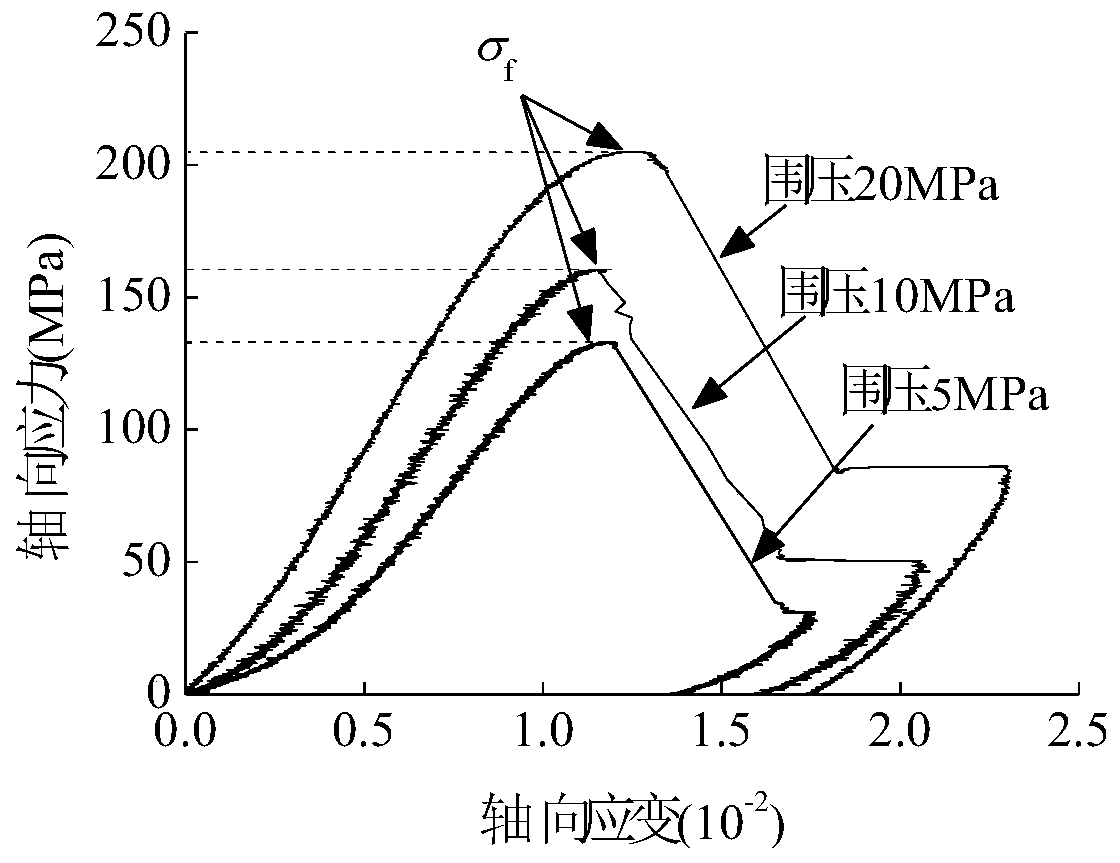

[0047] (4) Determine the confining pressure value P according to the site conditions; carry out conventional uniaxial (confining pressure P is 0) or triaxial (confining pressure P is not 0) tests on the samples of group A to determine the rock peak stress value σ f or rock peak strain value ε f ;

[0048] (5) The graded cyclic loading and unloading test under the above confining pressure value P is carried out on the samples of group B. The unloading point before the peak takes the above rock peak stress val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com