Method for measuring residue stress and metal material elastic-plastic mechanical property by continuous press mark method

A technology of residual stress and metal materials, applied in the direction of testing material hardness, analyzing materials, measuring devices, etc., can solve the problems of increasing complexity and experiment cost, difficulty, increasing experiment complexity, etc., so as to save experiment cost and improve experiment efficiency. Efficiency, reliable calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

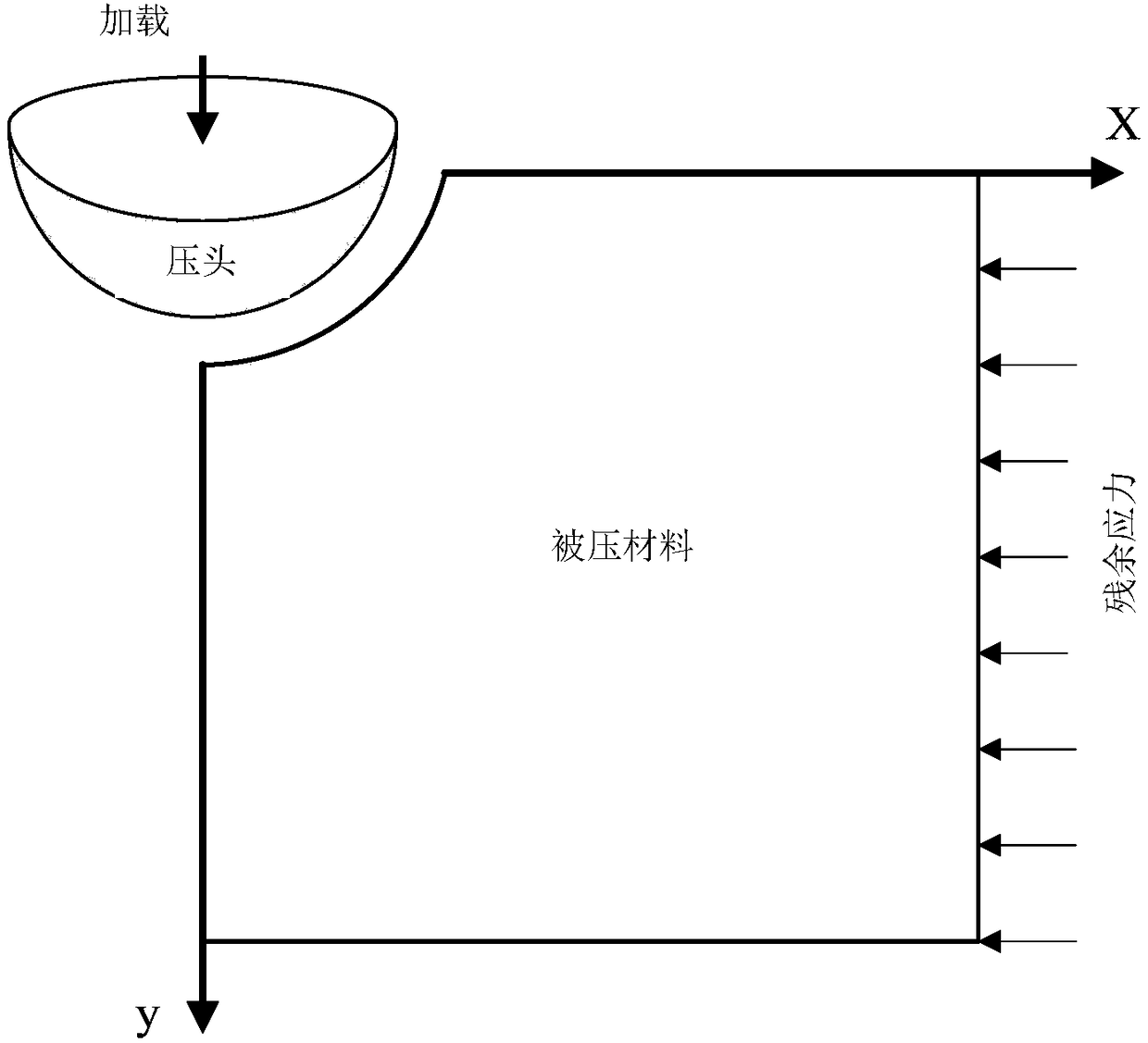

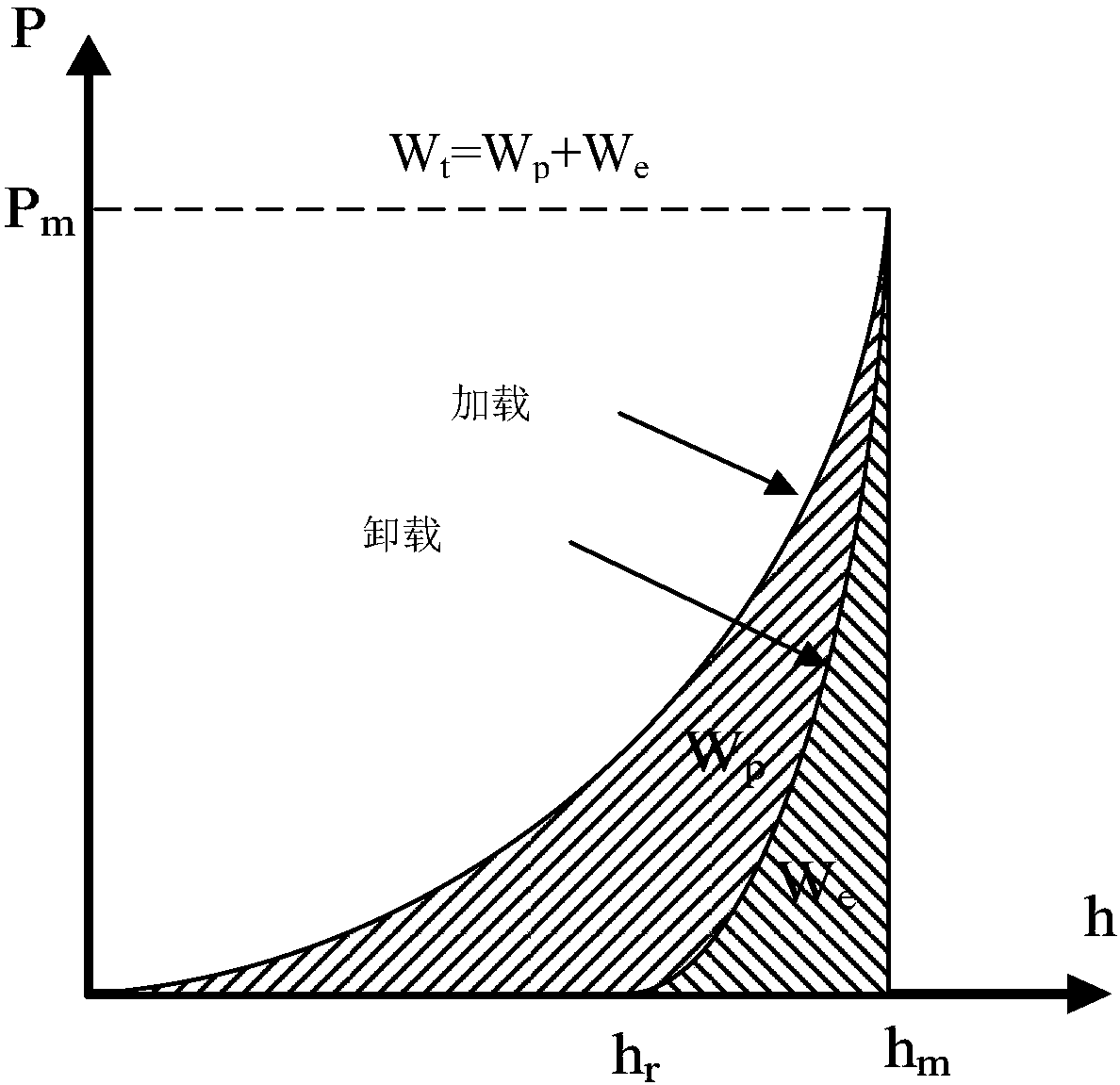

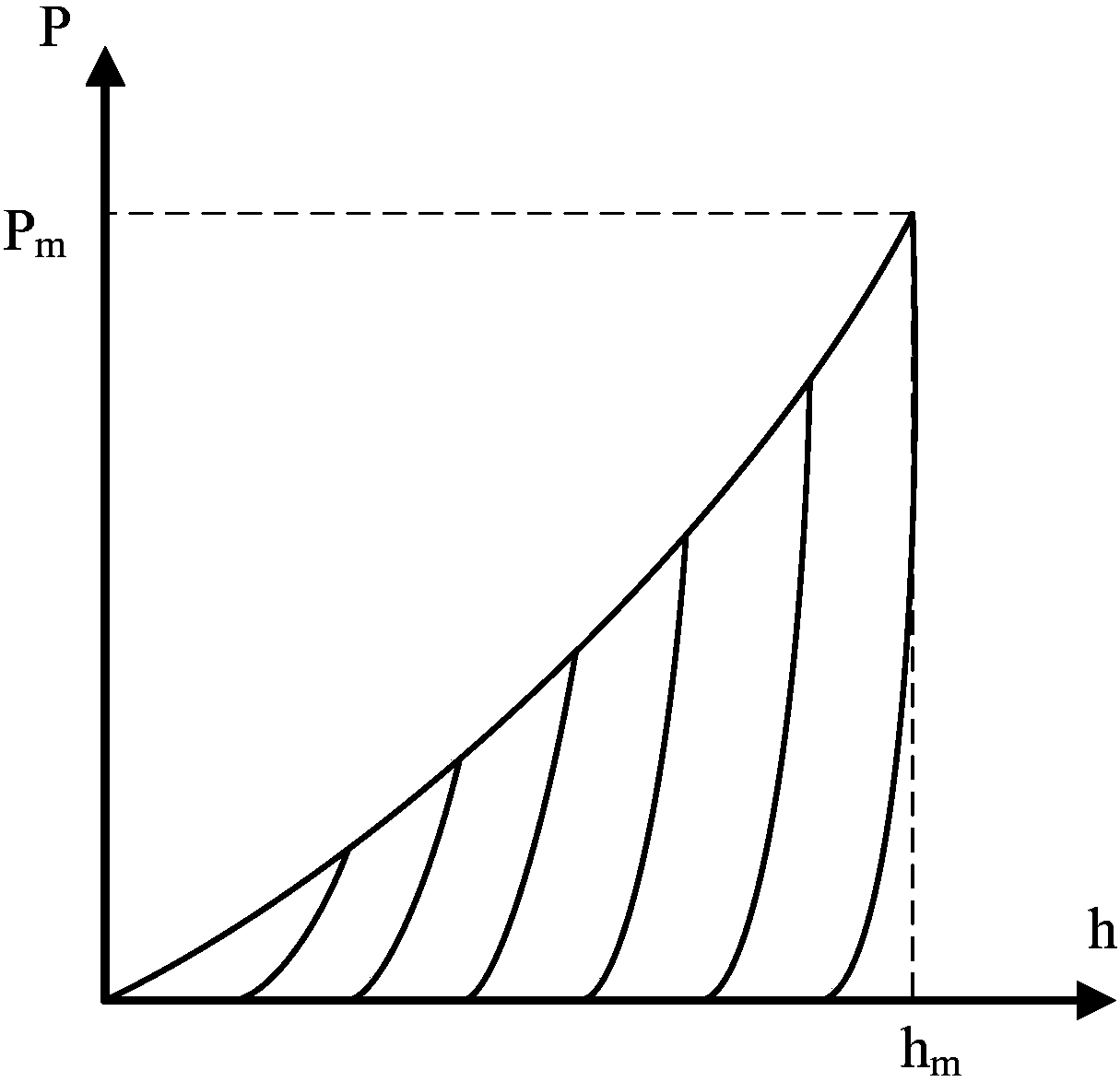

[0045] Such as figure 1 Shown is a schematic diagram of a typical ball indentation simulation experiment. The indenter is a rigid ball indenter with a radius of R. It can be considered that the shape of the indenter does not change during the indentation process. Load simulation isometric residual stress σ r . Such as Figure 2a Is the load-displacement curve of a single loading and unloading process, loading work W t Is the integral area under the load curve and the coordinate axis, the elastic recovery work W e Is the integral area under the unloading curve and the coordinate axis, Wp is the plastic deformation work, and P is the loading load. Figure 2b It is a schematic diagram of the load-displacement curve of the cyclic loading process. Through continuous loading and unloading, the p-h curve at different depths can be quickly obtained, which greatly improves the efficiency of the experiment.

[0046] The ABAQUS finite element analysis software is used to simulate 252 kinds...

Embodiment 2

[0076] In this example, two materials with known elastoplastic parameters, S45C and API X42, are tested and verified. It is assumed that the two materials have ideal residual stress σ. r =±0.3σ y And ±0.6σ y , The specific material parameters are shown in Table 3.

[0077] Finite element simulation is used to obtain the indentation parameters at different depths, and the indentation power ratios at the indentation depth h=0.01R, 0.06R, and 0.07R are selected as the analysis parameters. This can be obtained by formula (4) in Example 1. The apparent strain value at depth, combined with equation (5), Table 2 and the inverse analysis method in Example 1, can calculate the yield strength σ of the material y , Residual stress σ r , The strain hardening index n, see Table 3.

[0078] table 3

[0079]

[0080] Figure 9 shows the comparison of the stress-strain relationship predicted by the inversion of the two materials S45C and API X42 with the stress-strain relationship of the original rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

| strain hardening exponent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com