Container of filling body stability monitoring device under corrosion condition and manufacturing method

A technology for monitoring devices and filling bodies, which is applied to rigid containers, measuring devices, containers, etc., can solve problems such as inability to simultaneously fill bodies, and achieve the effects of maintaining good bonding performance, good integrity, and accelerating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in conjunction with the accompanying drawings.

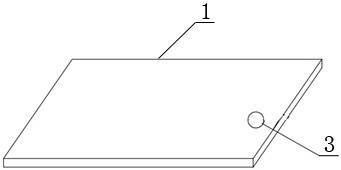

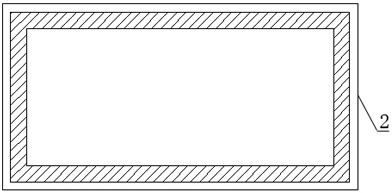

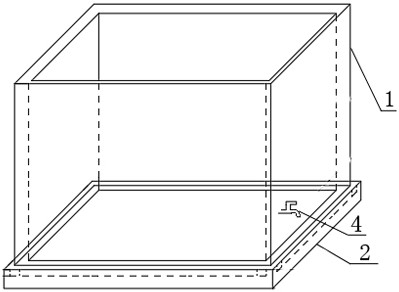

[0030] As shown in the figure, a container for a filling body stability monitoring device under corrosive conditions includes a container body with a rectangular cross-section, and the container body includes four side walls 1 made of tempered glass and a bottom plate 2 made of stainless steel plate , the surface of the bottom plate 2 is respectively provided with grooves close to the edge, one end of the side wall 1 is respectively located in the groove of the bottom plate 2, the two ends of the side wall 1 are connected in turn, and the connecting ends of the side wall 1 are connected from the inside to the outside. A glass glue layer and an epoxy resin layer are provided in sequence, a glass glue layer is arranged between the grooves of the side wall 1 and the bottom plate 2, and a paint layer is provided on the inner surfaces of the side wall 1 and the bottom plate 2 resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com