Method capable of preventing pre-existing cracks against closure by adoption of high-energy gas fracture

A high-energy gas fracturing and pre-storage technology, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., to achieve the effect of low construction cost, tight connection and fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

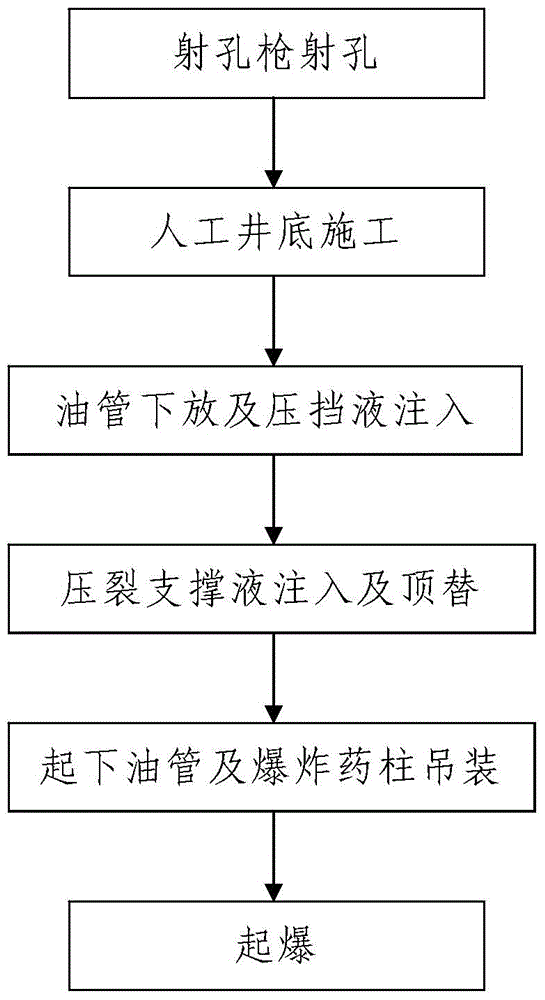

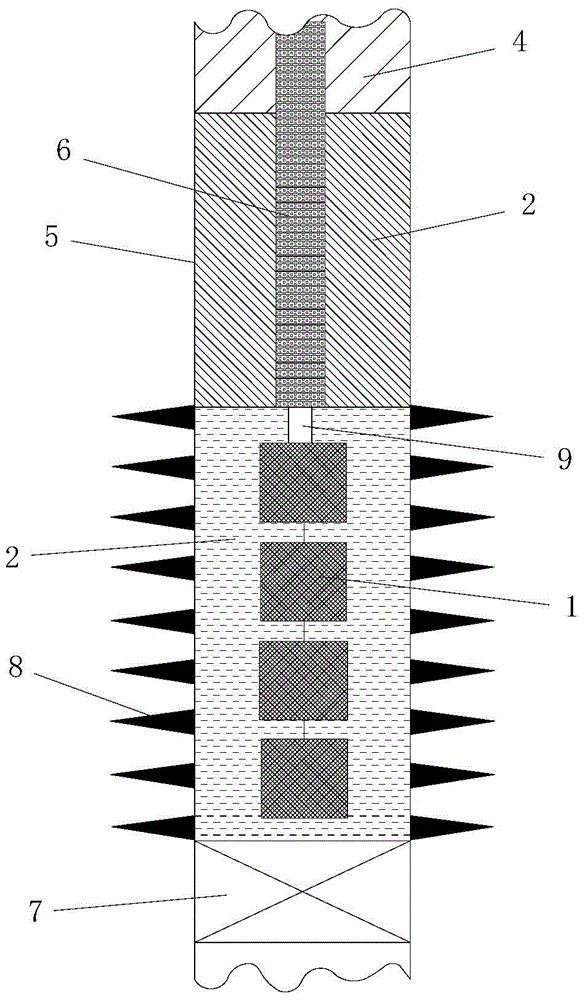

[0047] Such as figure 1 , figure 2 A method for preventing the closure of pre-existing fractures in high-energy gas fracturing includes the following steps:

[0048] Step 1. Perforating with a perforating gun: Perforating with a perforating gun lowered into the wellbore of an oil and gas well, and forming a plurality of perforation holes 8 in the target interval. Fractured oil and gas reservoirs.

[0049] In this embodiment, the plurality of perforation holes 8 are arranged horizontally.

[0050] Step 2. Artificial well bottom construction: construction of an artificial well bottom at the bottom of the wellbore of the oil and gas well, the artificial well bottom is located at the bottom of the casing 5 in the oil and gas well and below the target interval.

[0051] Step 3: lowering the tubing and injecting the blocking fluid: lower the tubing 6 to the position of the target layer described in step 1, and inject the blocking fluid 4 into the wellbore of the oil and gas well...

Embodiment 2

[0095] In this embodiment, the difference from Embodiment 1 is that: the hydrophobic spacer 3 described in step 401 and step 403 is formed by uniformly mixing carbon tetrachloride and diesel oil in a volume ratio of 45:100; Fracture propping fluid 2 is composed of the following raw materials in mass percentage: thickener: 0.72%; clay stabilizer: 0.45%; crosslinking agent: 0.25%; gel breaker: 0.60%; pH regulator: 0.33%; Agent: 27%; The balance is water; And, the mass percentage of the first gel breaker is 0.35%, and the mass percentage of the second gel breaker is 0.25%; The propellant that solid propellant grain 1 adopts in step five The agent is a bisaryl magnesium propellant.

[0096] In this embodiment, the construction methods and construction parameters of the remaining steps are the same as those in Embodiment 1.

Embodiment 3

[0098] In this example, the difference from Example 1 is that the fracturing support fluid 2 in step 402 is composed of the following raw materials in mass percentage: thickener: 0.64%; clay stabilizer: 0.33%; crosslinking agent: 0.25% %; gel breaker: 0.36%; pH regulator: 0.35%; fracturing proppant: 25.2%; the balance is water; the gel breaker is WBK-143L gel breaker or Breaker 3L gel breaker; step five The propellant used in the solid propellant grain 1 described above is a bisaryl-3 composite propellant.

[0099] In this embodiment, the construction methods and construction parameters of the remaining steps are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com