Cement grinding aid and preparation method thereof

A technology of cement grinding aid and defoaming agent, applied in the field of cement grinding aid and its preparation, can solve the problems of unstable performance of grinding aid, decrease of cement contribution rate, high price and cost, and achieve good grinding aid effect and prevent The effect of agglomeration and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

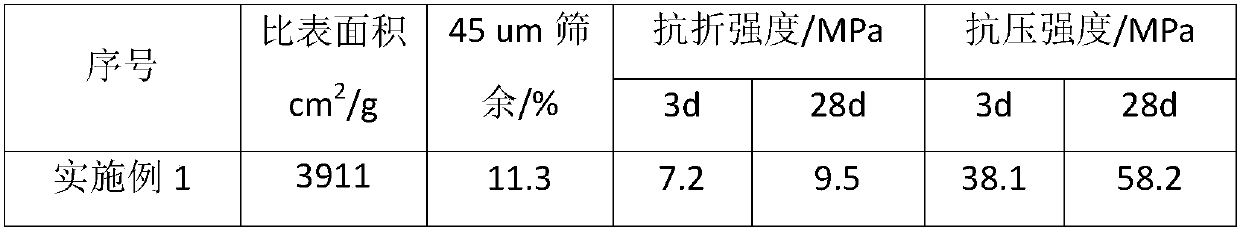

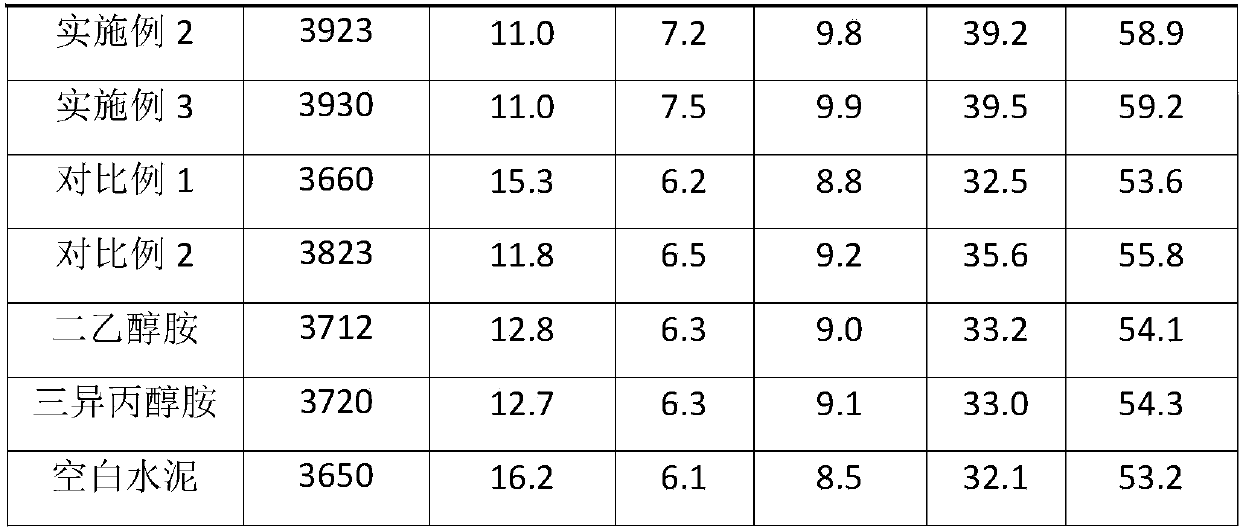

Examples

Embodiment 1

[0028] A cement grinding aid, which is prepared from the following raw materials in parts by weight: 10 parts of modified alcohol amine type grinding aid component, 5 parts of isooctyl phosphate, 0.5 part of thickening dispersant, and 0.5 part of surfactant , 0.1 part of defoamer, 10 parts of water; the modified alcohol amine type grinding aid component is prepared by the following steps:

[0029] (1) Add maleic anhydride and diethanolamine into a three-necked flask protected by nitrogen gas, stir and heat to 70°C, and keep a constant temperature to test the pH value of the system. When the pH value is 6-7, stop heating and lower the temperature. After reaching room temperature, obtain mother liquor;

[0030] (2) Mix initiator, chain transfer agent and deionized water according to the mass ratio of 1:2:3 to obtain liquid A;

[0031] (3) Mix acrylic acid, mother liquor obtained in step (1) and deionized water according to a mass ratio of 1:2:5 to obtain liquid B;

[0032] (4)...

Embodiment 2

[0046] A cement grinding aid, which is prepared from the following raw materials in parts by weight: 20 parts of modified alcohol amine type grinding aid components, 7 parts of isooctanyl phosphate, 0.8 parts of thickening and dispersing agent, and 0.8 parts of surfactant , 0.3 parts of defoamer, 13 parts of water; the modified alcohol amine type grinding aid component is prepared by the following steps:

[0047] (1) Add maleic anhydride and diethanolamine into a three-necked flask protected by nitrogen gas, stir and heat to 70°C, and keep a constant temperature to test the pH value of the system. When the pH value is 6-7, stop heating and lower the temperature. After reaching room temperature, obtain mother liquor;

[0048] (2) Mix initiator, chain transfer agent and deionized water according to the mass ratio of 1:2:3 to obtain liquid A;

[0049] (3) Mix acrylic acid, mother liquor obtained in step (1) and deionized water according to a mass ratio of 1:2:5 to obtain liquid ...

Embodiment 3

[0059] A cement grinding aid, which is prepared from the following raw materials in parts by weight: 30 parts of modified alcohol amine type grinding aid components, 8 parts of isooctanyl phosphate, 1 part of thickening and dispersing agent, and 1 part of surfactant , 0.5 parts of defoamer, 15 parts of water; the modified alcohol amine type grinding aid component is prepared by the following steps:

[0060] (1) Add maleic anhydride and diethanolamine into a three-necked flask protected by nitrogen gas, stir and heat to 70°C, and keep a constant temperature to test the pH value of the system. When the pH value is 6-7, stop heating and lower the temperature. After reaching room temperature, obtain mother liquor;

[0061] (2) Mix initiator, chain transfer agent and deionized water according to the mass ratio of 1:2:3 to obtain liquid A;

[0062] (3) Mix acrylic acid, mother liquor obtained in step (1) and deionized water according to a mass ratio of 1:2:5 to obtain liquid B;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com