Precise proppant placing method aiming at natural fracture development gas pool hydrofracture

A technology of natural fractures and hydraulic fracturing, which is applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of poor stimulation and reconstruction effect of oil and gas reservoirs, inability to transport proppant, and low communication efficiency of natural fractures. Achieve the effect of improving the effect of increasing production, improving the laying efficiency, and optimizing the thickness of the perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

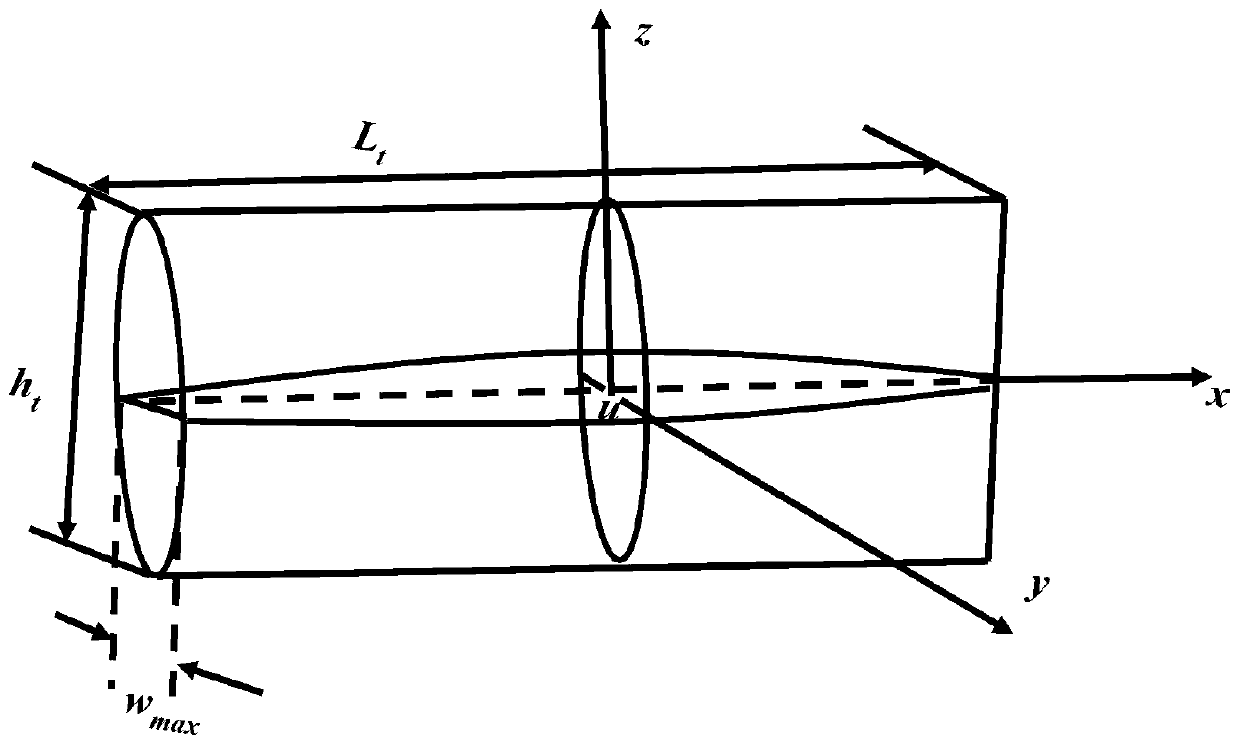

[0037] Taking single well C in an oilfield as an example, the well has developed natural fractures, the designed hydraulic fracturing interval has a burial depth of 3608.0-3625.0 m, an average formation temperature of 120 °C, and a formation closure pressure of 43 MPa.

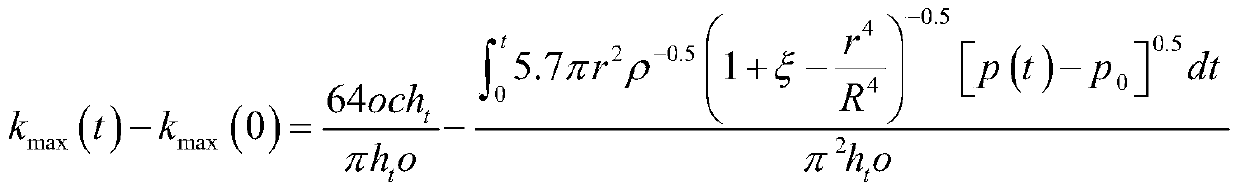

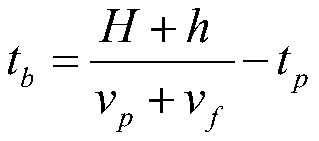

[0038] (1) According to the preliminary laboratory test results, the density of the fracturing fluid is 1250kg / m 3 , the fracturing fluid viscosity is 0.25Pa·s, the proppant particle diameter is 0.0006m, the sand ratio is 15% (that is, the volume fraction of liquid in the mixture of proppant and fracturing fluid is 89.7%), and the fracture closure time after stopping the pump 5000s, the vertical downward migration velocity of the sand-carrying fluid in the fracture is 0.002m / s, the casing fracturing wellbore radius is 39mm, the choke radius is 1.5mm, and the wellhead pressure during the flowback process is 2MPa;

[0039] (2) Since the formation closure pressure P=43MPaz 1500kg / m 3 ; The liquid density ρ of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com